Computer-controlled, High-speed, Bartacking Sewing System

Inspire the Knowledge in Sewing Adjustment.

Epoch-making Sewing Systems in history.

Digital sewing system proposes the production process added with a computerized new value to all the people who engage in production.

Product overview

Product features

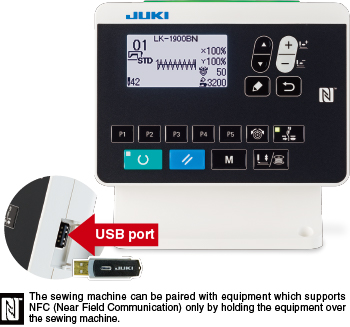

Machine is mounted with inbuilt NFC (Near Field Communication) and communication devices capable of a 2-way data transmission

Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially- available Android tablet in contactless mode.

This enables quick check for uniform settings as well as confirmation of conditions of sewing machines in a sewing line, thereby facilitating setup changes.

The operation panel is also provided as standard with a USB port. Data management and software update can be carried out with ease using a USB thumb drive.

Data items of sewing can be numerically managed to ensure “stable quality” and “reduction in time required for setup changes”. Quantified sewing data can be externally taken from the sewing machine using an Android tablet or USB thumb drive.

*Android OS Version 6.0 is recommended to use JUKI Smart APP.

(Operation is confirmed with respect to Versions 5.0 and later.)

Contact JUKI distributor in your area for how to use the application software.

Basic performance

Higher productivity

The machine achieves sewing speed of 3,200sti/min. The machine's starting, stopping, thread-trimming and automatic presser lifting speeds have been increased to significantly shorten total cycle time.

Excellent workability and operability

(Low-noise and low-vibration)- The direct-drive head (with no belt), which is directly connected to a compact AC servomotor, achieves outstanding. This head helps create a comfortable working environment with reduced vibration and noise.

- The arm section of the machine head is fitted with a hand pulley. This allows the operator to visually check the needle entry points.

Excellent seam quality

Needle thread grasping mechanism helps produce consistent knot tying at the beginning of sewing. (This device has been factory-set to “invoking prohibited” status at the time of delivery.)

The sewing starting point can be corrected

In cases where the needle entry point for button sewing is to be corrected, the sewing starting point can be corrected without the adjustment of the relevant mechanism.

Auto-lifter mechanism utilizing a system

- The machine is provided as standard with auto-lifter that uses a stepping-motor system. This helps reduce operator fatigue.

- It is also possible to change over the stroke of the auto-lifter from a onestep stroke to a double-step stroke, which offers easier positioning of a material on the machine. For the double-step stroke, an intermediate stopping height can be established on the operation panel.

- The work clamp foot lift can be set to a maximum of 17mm. (Standard 14mm)

Oil stains are eliminated

- Thanks to our advanced dry-head technology, the frame (needle bar and thread take-up) no longer requires lubrication. This prevents the material from being stained with lubricating oil.

- Just a small quantity of clean oil is supplied from the oil tank to the hook.

Eco-friendly power saving

An encoder is installed in the pulse motor, thereby achieving substantially improved power-consumption saving.

LED Light

The LED light can adjust the light intensity to 5 levels, and Off setting is also possible.

The operator can set the brightness which is easy to work, improving work efficiency.

Optimal specifications are available according to the material

Since the H specification has enhanced needle penetration, the ability to handle thick materials has been further improved.

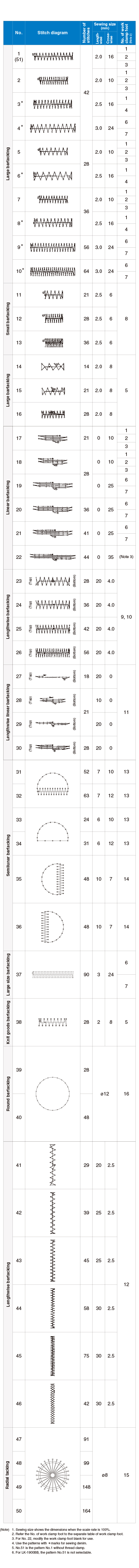

With the W specification, the use of a cauldron reduces the frequency of bobbin thread replacement, enabling efficient work.TABLE OF THE STANDARD PATTERNS

Specification

| Model name | LK-1900BN-HS | LK-1900BN-WS | ||

|---|---|---|---|---|

| Application | For heavy-weight materials | With large hook for heavy-weight materials | ||

| Max. sewing speed | 3,200sti/min* | 2,700sti/min* | ||

| Sewing area | 30mm (L) × 40mm (W) | |||

| Stitch length | 0.1~10mm (0.1mm step) | |||

| Needle bar stroke | 41.2mm | |||

| Lift of the work clamp foot | Standard 14mm (17mm when the reverse-rotation needle-up function) | |||

| Auto-lifter | Provided as standard (stepping motor type) | |||

| Needle thread tension | Active tension (electronic thread tension control system) | |||

| Needle (at the time of delivery) | DP×17 (#21) | |||

| Hook | Standard shuttle hook | Large shuttle hook | ||

| Number of stitches that can be stored in memory |

Max. 20,000 stitches | |||

| Number of standard patterns | 51 patterns | |||

| Number of data that can be input | 200 patterns (for up to 150 patterns, sewing data can be added.) | |||

| Enlarging/Reducing facility | 20~200% (1% step), Pattern enlargement/reduction can be done by increasing/decreasing the stitch length |

|||

| Memory method | Internal-organs memory | |||

| Bobbin thread counter | Provided as standard (up/down method) | |||

| Lubrication | Hook: minute-quantity lubrication | |||

| Lubricating oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) | |||

| Sewing machine motor | 450W compact AC servomotor (direct-drive system) | |||

| Power consumption | 250VA | |||

| Weight | Machine head (include motor) 42kg, Control box 5.6kg | |||

*sti/min is the abbreviation for “stitches per minute”

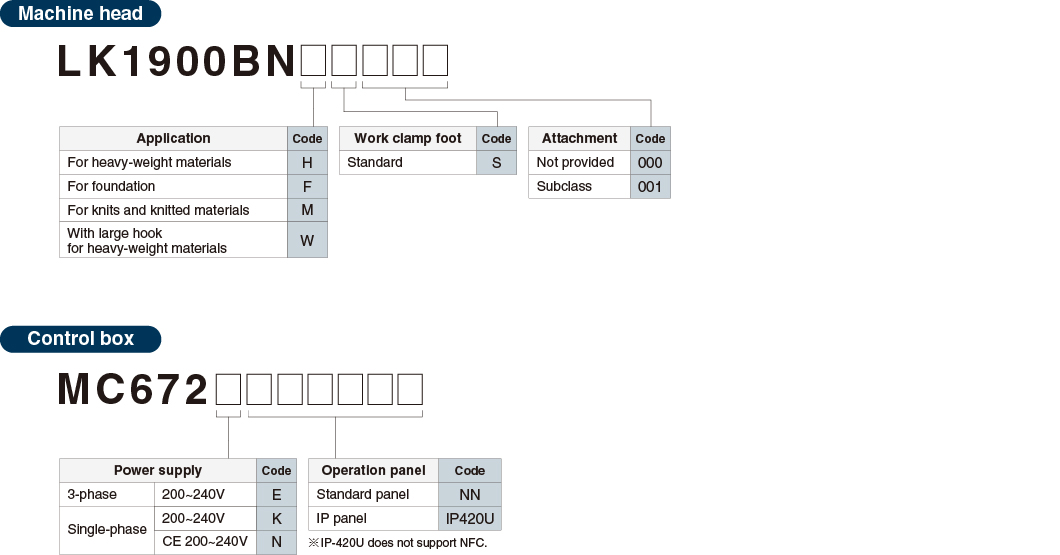

When you place orders

Gauge

LK-1900BN-HS

LK-1900BN-WS

| Guage: OP | WALK CLAMP FOOT ASM. | WALK CLAMP FOOT_RIGHT | WALK CLAMP FOOT_LEFT |

|---|---|---|---|

| Figure |  |

||

| Remarks | P/N | P/N | P/N |

| - | 13518659 | 13518600 | 13518709 |

| - | 13548557 | 13548508 | 13548607 |

| - | 13548151 | 13548102 | 13548201 |

| - | 13542451 | 13542402 | 13542501 |

| For knitted fabric | 13542964 | 13542915 | 13543012 |

| - | 13571955 | 13571955 | 13571955 |

| Guage: OP | FEED PLATE | CLOTH PRESSER LOWER PLATE | FEED PLATE BLANK | FEED PLATE | FEED PLATE |

|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

| - | P/N | P/N | P/N | P/N | P/N |

| A | 14116107 | 14137707 | 14120109 | 40021855 | - |

| B | 14116206 | - | 14120208 | 40021856 | - |

| C | 14116305 | - | 14120505 | 40021857 | - |

| D | 14116404 | - | 14120307 | - | 40021858 |

| E | 14116503 | - | 14120406 | - | 40021859 |

| F | 14116602 | - | - | - | - |

| G | 14116701 | - | - | - | - |

| H | 14116800 | - | - | - | - |

| I | 14116909 | - | - | - | - |

| - | 13548003 | - | - | - | - |

| - | 13554506 | - | - | - | - |

| D9-14 | 13554803 | - | - | - | 40021873 |

| 12 | - | - | - | 40021876 | |

| 10 | - | - | - | 40021879 | |

| 14 | - | - | - | 40021882 |

| Guage: OP | CLOTH PRESSER BLANK_RIGHT | CLOTH PRESSER BLANK_LEFT |

|---|---|---|

| Figure |  |

|

| Remarks | P/N | P/N |

| Plating | 14121701 | 14121800 |

| No plating | 14121909 | 14122006 |

| Plating | 40021851 | 40021852 |

| No plating | 40021853 | 40021854 |

| Guage: OP | INNER HOOK PRESSER ASM. | NEEDLE HOLE GUIDE | |

|---|---|---|---|

| Figure |  |

|

|

| - | P/N | P/N | Remarks |

| 14103253 | B2426280000 | - | |

| 14103352 | B242628000B | Thick needle | |

| 14103659 | 14109607 | - | |

| B1817210DAD | D2426282C00 | For knitted fabric | |

| - | D2426MMCK00 | - | |

| Guage: OP | FINGER GUARD | |||

|---|---|---|---|---|

| Figure |  |

|

|

|

| - | P/N | P/N | P/N | P/N |

| 26224204 | 13573407 | 14120000 | 14135305 | |

| 13548300 | - | |||

| Remarks | - | Vertical bar | - | - |

| Guage: OP | WALK CLAMP FOOT ASM. | WALK CLAMP FOOT ASM._RIGHT | WALK CLAMP FOOT ASM._LEFT |

|---|---|---|---|

| Figure |  |

|

|

| P/N | 14121263 | 14121255 | 14121354 |

| Guage: OP | WALK CLAMP FOOT A_LEFT | WALK CLAMP FOOT A ASM._RIGHT | CLOTH PRESSER FOOT B_LEFT | CLOTH PRESSER FOOT B_RIGHT | WOLK CLAMP FOOT BLANK_LEFT | WOLK CLAMP FOOT BLANK_RIGHT |

|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

| P/N | 14137608 | 14137509 | 14137905 | 14137806 | 40021870 | 40021869 |

| Guage | WOLK CLAMP FOOT_LEFT | WALK CLAMP FOOT_RIGHT |

|---|---|---|

| Figure |  |

|

| Remarks | P/N | P/N |

| D9-14 | 40021872 | 40021871 |

| 12 | 40021875 | 40021874 |

| 10 | 40021878 | 40021877 |

| 14 | 40021881 | 40021880 |