Single Needle Lock-stitch Machine with Automatic Under trimmer

(Upper and Lower Feed type)

Our proven vertical feed mechanism and servo motor improve ease of use and increase productivity.

Product features

Basic performance

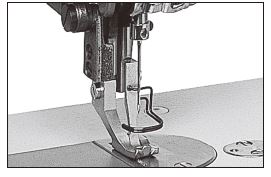

Vertical feed mechanism for reliable feeding

Uses vertical feed to clamp and reliably feed material that is difficult to feed.

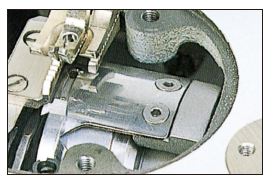

Stable thread cutting performance from thin to thick threads

Our proven left female rotating and right female fixed meshing system enables excellent cutting of thread from fine to thick threads (#6).

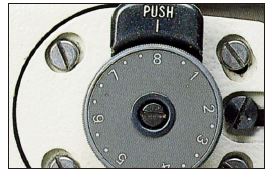

Stitch adjustment dial with simple forward/backward seam pitch adjustment lock

Adjustments can be easily made by turning the dial pin on the front of the arm.

Built-in detector that detects the position with high accuracy

Upper and lower needle stop positions can be separately adjusted with a single operation. The display lamp shows the power status at a single glance.

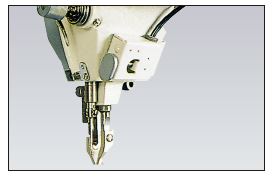

Hold-up lever on the front of the arm

The hold-up lever is equipped on the front of the arm for improved operability.

Touchback switch

Light touch for quick response. Enables needle raising and correction stitches.

Powerful and highperformanceLimiservo X G Series

・Comes with a simple sequence function.

・The reverse needle raising function enables easy insertion and removal of materials.

・The fabric stop function ensures proper needle drop location

Specification

| Mode | LY2-3750-B1T | ||

|---|---|---|---|

| Stitching styl | Single-needle lockstitch | ||

| Application | Thick items | ||

| Max. speed | 2,000sti/min* | ||

| Max. stitch length | 8mm | ||

| Holder lift stroke (manual) | 6mm | ||

| Holder lift stroke (knee) | 16mm | ||

| Needle | DP x 17 #22( DB x 1 #22) | ||

| Hook | Horizontal-axis 2.0 fold-capacity hook | ||

| Needle bar stroke | 38mm | ||

| Thread cutting equipment | Available | ||

| Touchback equipment | Available | ||

| Oil lubrication | Automatic oil lubrication system | ||

| Upper feed foot alternate amount | 2 to 5mm (dial system) | ||

| Bed shape | Flat bed system | ||

| Throat length | 335mm | ||

| Bed dimensions | 517 x 178mm | ||

| Mass | 34kg | ||

Note: Mass includes the mass of the sewing machine only.

Note: An operation caution sticker is attached to the sewing machine unit.

* sti/min is the abbreviation for “stitches per minute”