Electronically Controlled Pattern Sewing Machines

Sewing area 600 x 400mm

Product features

Basic performance

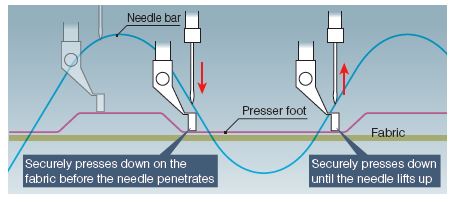

Fabric presser with optimal pressure

A new motion control allows the presser foot to press down on various types of fabric, from thin to thick materials, with optimal pressure.

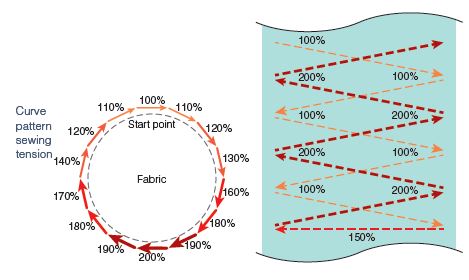

Optimizes thread tightness in all stitching directions

This function reduces variation in tightness according to the stitching direction and improve quality.

Faster and more attractive

The world’s highest class of actual sewing speed is achieved (as of April 2020).

Curves and large seams can be sewn quickly and beautifully.

* 3.0mm pitch: 2,300 sti/min*1 (PLK-J6040R intermittent feed)

Automatic checking of setting mistakes

The sewing machine checks the thickness of the fabric and detects setting mistakes prior to sewing.

The oiling timing of the hook is digitized to ensure proper oiling and prevent excessive oil use.

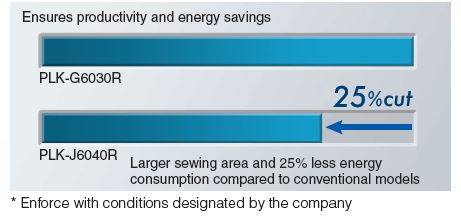

Excellent energy-saving effects

The new arm bed structure and new XY feed control realize low vibration and low sound, and thereby realize energy savings.

Stable thread interlocking from the first stitch

“Stitch interlock faults” are resolved by minimizing the flapping of fabric at the start of stitching.

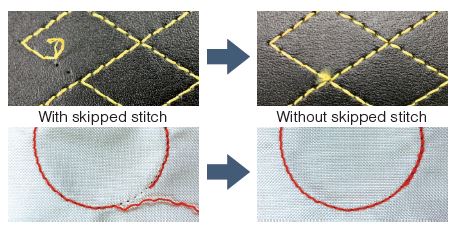

Detects stitching errors

In addition to visual detection by the operator, stitch errors (skipped stitches, thread breaks) are detected by the machine to help discover defective items.

*This function does not warranty all abnormal stitch detections. Depending on the sewing conditions, there may be undetected or false detection.

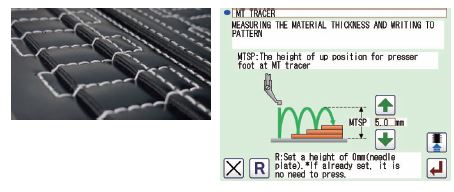

Faster adjustment of presser foot height

The height of the presser foot is adjusted after automatically measuring the overall fabric thickness along the stitching pattern.

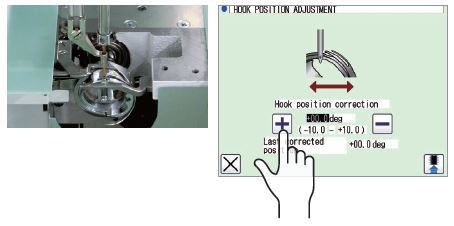

Faster adjustment and reproduction of past adjustments

The hook, presser foot, and thread trimmer are digitally adjusted.

Open/close window for bobbin exchange

Unlike conventional large models which required the operator to get under the sliding plate to replace the bobbin, the J series models have an open/close window on the sliding plate so that the bobbin can be easily exchanged. This greatly reduces the operator’s work.

Specification

| Model | PLK-J6040 | PLK-J6040R | PLK-J6040R3 | ||

|---|---|---|---|---|---|

| Stitching style | Single-needle lockstitch | ||||

| Hook | Double-size shuttle hook | Double-size rotary hook | Triple-size rotary hook | ||

| Needle | DP x 17 #18 | ||||

| Max. speed (Note 1) | Intermittent: 2,000 sti/min* Continuous: 2,000 sti/min* |

Intermittent: 2,300 sti/min* Continuous: 2,500 sti/min* |

|||

| Feeding system | Intermittent or continuous (switchover method) | ||||

| Stitch length | 0.1 to 20.0mm (min. resolution 0.1mm) | ||||

| Max. stitches | 20,000 stitches/pattern | ||||

| Max. patterns (Note 2) | 9,000 | ||||

| Memory medium | USB flash memory | ||||

| Work holder | Chucking system | ||||

| Thread break detection, skipped stitch detection (Note 3) | Standard equipment | ||||

| Outline dimensions | 1,350 x 1,570 x 1,205mm (WxDxH) | ||||

| Mass | 440kg | ||||

| Power supply | 200 to 240V single-phase/three-phase | ||||

*sti/min is the abbreviation for “stitches per minute”

Note 1: Sewing speed may be limited by the type of sewing material, presser weight, stitch length, etc.

Note 2: Max. patterns may be limited depending on the number of stitches per pattern in the memory.

Note 3: Detection of all stitch errors is not guaranteed. Always complete adjustments according to the stitching conditions before use.