Super-high-speed, Overlock / Safety Stitch Machine

High-quality machine with easier operation and increased reliability. The MO-6900S Series is a new and powerful overlock/safety stitch machine that has been developed to offer increased reliability and ease-of-use, while upgrading seam quality at higher sewing speeds. It responds to a wider range of materials and processes to finish high-quality soft-feeling seams. With the operating noise having been reduced and increased durability ensured, the cost-effective MO-6900S Series is a leading machine in the new era.

PEGASUS : EX series

Product features

The machine ensures both beautiful and upgraded seam quality at higher speeds

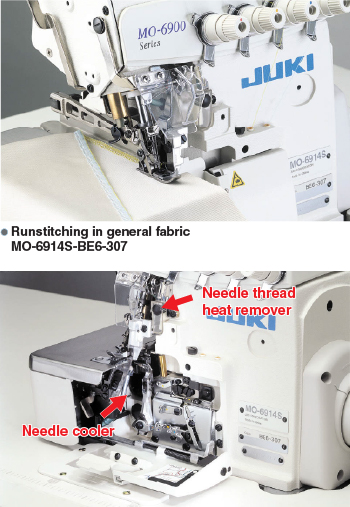

Since the machine comes with a needle-thread take-up mechanism as well as a looper thread take-up mechanism, to offer upgraded responsiveness from light- to heavy-weight materials with a lower applied tension, it achieves well-tensed soft-feeling seams that flexibly correspond to the elasticity of the material at the maximum sewing speed of 8,000 to 8,500sti/min.

To offer improved sewing capabilities as well as to prevent stitching misshapes, the machine is equipped as standard with the needle thread heat remover and needle cooler.

Further increased reliability

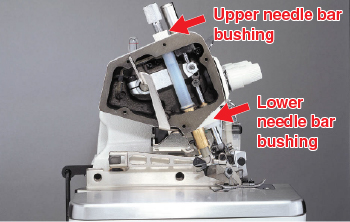

The introduction of a shield-structured needle bar mechanism and upper and lower needle bar bushings, contributes to increased durability and reliability.

Additionally, the machine incorporates an improved feed mechanism and upper looper unit as well as coming standard with a cartridge type oil filter and cooling fan, thereby ensuring enhanced reliability.

Devices intended for conventional JUKI machines are also interchangeable

Gauges and devices you have used with your existing JUKI machines are also interchangeable with no additional machining required (excluding the LB Series). This eliminates both the waste of resources and unwanted extra costs.

The machine has been developed with the intention of providing an extended service life

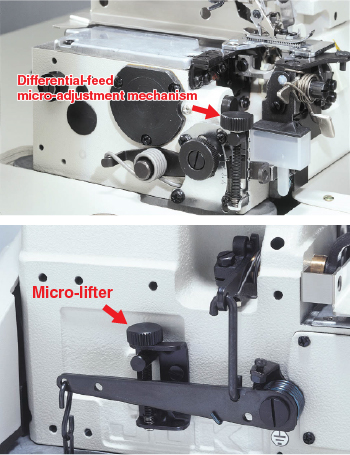

The machine incorporates various mechanisms as standard, such as a differential-feed micro-adjustment mechanism and an external adjustment mechanism for adjusting the feed dog inclination as well as increasing the differential feed ratio, which can be easily adjusted to finish seams that perfectly match the material to be used. Comfortable operation is all but guaranteed, by a wider area around the needle entry, the adoption as standard of a micro-lifter feature that offers improved responsiveness to materials and provides the operator with upgraded operability, and by the reduction of operating noise and vibration, which has been achieved by designing an optimally balanced machine.

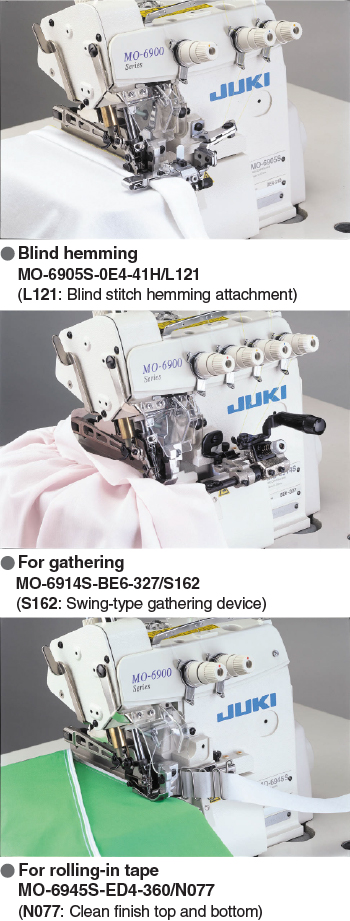

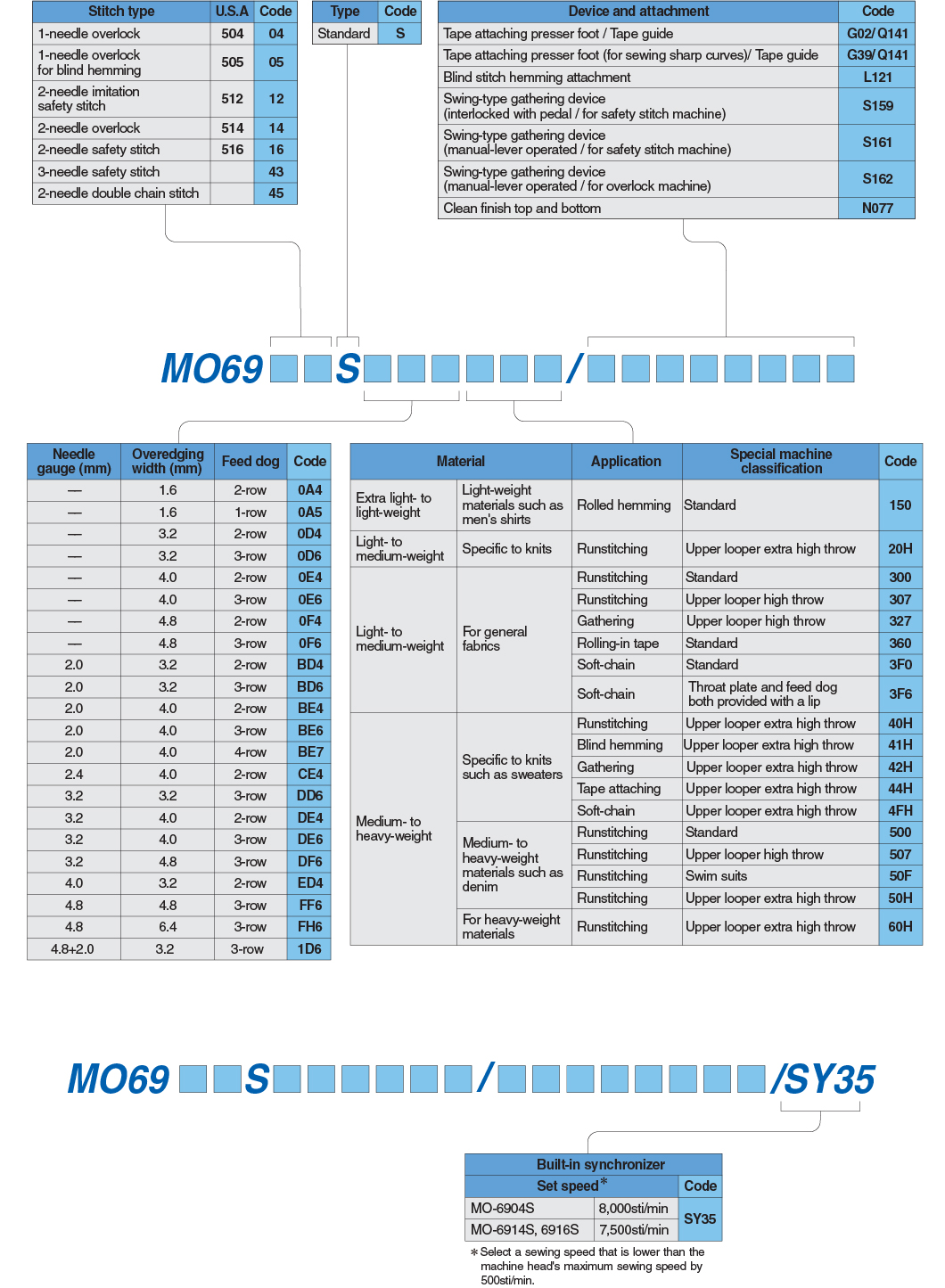

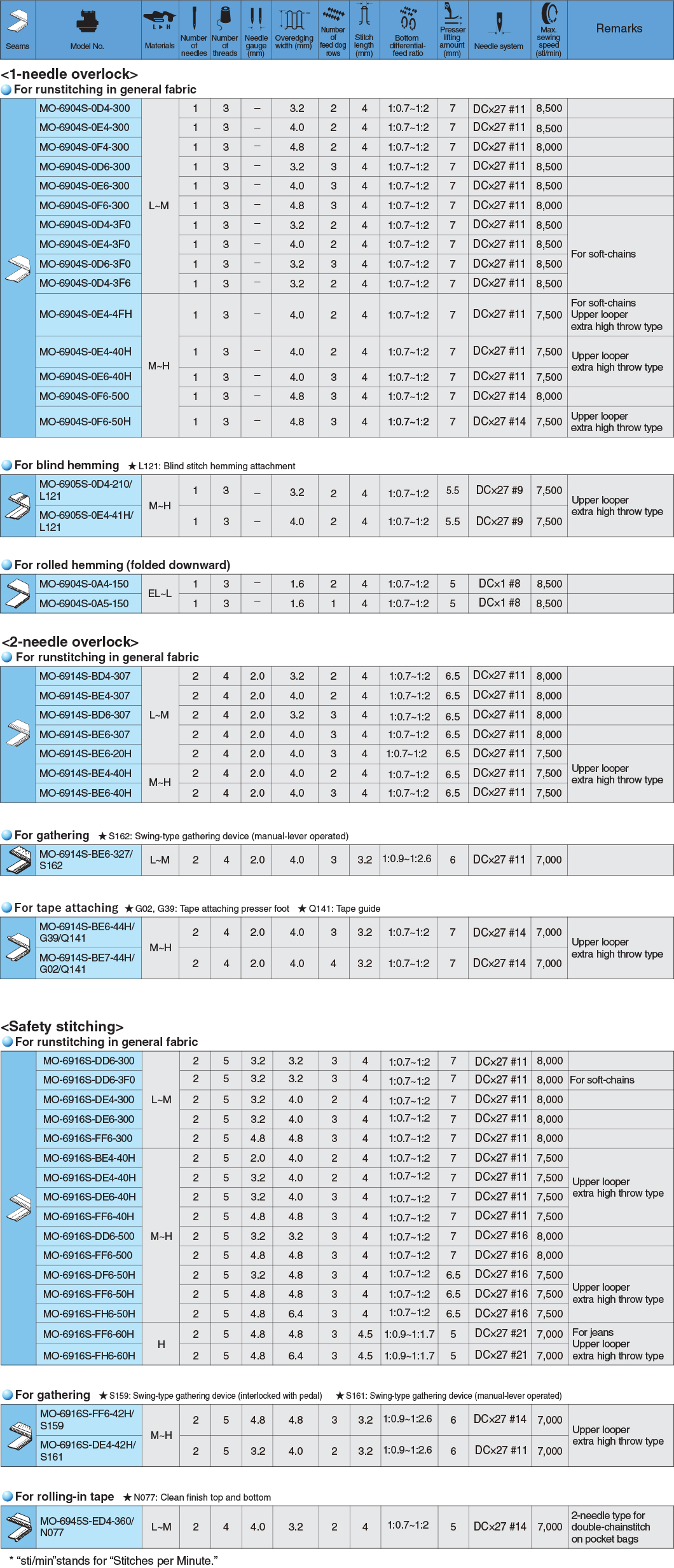

A variety of subclass machines is available

Specification

| Model name | MO-6904S | MO-6914S | MO-6916S | |

|---|---|---|---|---|

| Stitch type | 1-needle overlock | 2-needle overlock | Safety stitching | |

| Stitch style in the U.S.A. | 504 | 514 | 516 | |

| Max. sewing speed | 8,500sti/min* | 8,000sti/min* | ||

| Stitch length | 0.8~4mm | 1.5~4mm | ||

| Needle gauge (mm) | - | 2.0, 2.4, 3.2 | 2.0, 3.2, 4.0, 4.8, 4.8+2.0 | |

| Overedging width (mm) | 1.6, 3.2, 4.0, 4.8 | 3.2, 4.0, 4.8 | 3.2, 4.0, 4.8, 6.4 | |

| Differential feed ratio | For gathering 1:2 (max. 1:4), For stretching 1:0.7 (max. 1:0.6) | |||

| Needle bar stroke | 24.5mm | |||

| Inclination angle of the needle | 20° | |||

| Needle bar bushing | Upper/lower bushing method | |||

| Needle | DC×27(excluding some subclass model) | |||

| Max. lift of the presser foot | 7mm(excluding some subclass model) | |||

| Max. presser foot pressure | 63.7N (6.5kgf) | |||

| Stitch adjusting method | By push-button | |||

| Differential-feed adjusting method | By lever (with micro-adjustment) | |||

| Weight of the machine head | 28kg | |||

| Lubrication | Automatic | |||

| Lubricating oil | JUKI Machine Oil 18 (equivalent to ISO VG18) | |||

| Needle cooler | Provided as standard | |||

| Needle thread heat remover | Provided as standard | |||

| Micro-lifter | Provided as standard | |||

* “sti/min”stands for “Stitches per Minute.”

When you place orders

Subclass machine list

Gauge

MO-6904S-0D4-300

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2 | R4200J6DD00 | 13191606 | 13191309 | 13192802 | 11876166 | 11872009 | B1507804C00 | B1509804C00 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 3.2 | 13131057 | 40015637 |

MO-6904S-0E4-300

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | R4200J6ED00 | 13191606 | 13191309 | 13192802 | 11876166 | 11872009 | B1507804C00 | B1509804C00 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 4.0 | 13131057 | 40015637 |

MO-6904S-0F4-300

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8 | R4200J6FD00 | 13191606 | 13191309 | 13192802 | 11876257 | 11872009 | B150781400P | B1509804C0A | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 4.8 | 13131057 | 40015637 |

MO-6904S-0D6-300

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2 | R4300J6DE00 | 11882206 | 13191309 | 11885100 | 11876356 | 11872009 | 11873007 | B1509804C00 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 3.2 | 13131057 | 40015637 |

MO-6904S-0E6-300

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | R4300J6EE00 | 11882206 | 13191309 | 11885100 | 11876356 | 11872009 | 11873007 | B1509804C00 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 4.0 | 13131057 | 40015637 |

MO-6904S-0F6-300

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8 | R4300J6FE0B | 11882206 | 13191309 | 11885100 | 11876455 | 11872009 | 11873007 | B1509804C0A | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 4.8 | 13131057 | 40015637 |

MO-6904S-0D4-3F0

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2 | R4200J6DD0A | 13191606 | 13191309 | 13192802 | 11876158 | 11872009 | B1507804C00 | B1509804C00 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 3.2 | 13131057 | 40015637 |

MO-6904S-0E4-3F0

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | R4200J6ED0A | 13191606 | 13191309 | 13192802 | 11876158 | 11872009 | B1507804C00 | B1509804C00 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 4.0 | 13131057 | 40015637 |

MO-6904S-0D6-3F0

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2 | R4300J6DE0A | 11882206 | 13191309 | 11885100 | 11876356 | 11872009 | 11873007 | B1509804C00 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 3.2 | 13131057 | 40015637 |

MO-6904S-0D4-3F6

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2 | R4200J6DD0C | 11597101 | 13191309 | 11886207 | 11876158 | 11872009 | B1507804C00 | B1509804C00 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 3.2 | 13131057 | 40015637 |

MO-6904S-0E4-4FH

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 1.6 | R4200J6ED0A | 13191606 | 13191309 | 13192802 | 11876059 | 11872009 | B1507804C00 | B1509804C00 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 1.6 | 11991908 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 1.6 | 13131156 | 40015637 |

MO-6904S-0E4-40H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | R4200J6ED00 | 13191606 | 13191309 | 13192802 | 11876158 | 11872009 | B1507804C00 | B1509804C00 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | 11991908 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 4.0 | 13131156 | 40015637 |

MO-6904S-0E6-40H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | R4300J6EE00 | 11882206 | 13191309 | 11885100 | 11876356 | 11872009 | 11873007 | B1509804C00 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | 11991908 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 4.0 | 13131156 | 40015637 |

MO-6904S-0F6-500

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8 | B4300J6FE0B | 11883303 | 13191309 | 11885605 | 11876455 | 11872009 | 11873007 | B1509804C0A | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 4.8 | 13131057 | 40015637 |

MO-6904S-0F6-50H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | B4300J6FE0B | 11883303 | 13191309 | 11885605 | 11876455 | 11872009 | 11873007 | B1509804C0A | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | 11991908 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 4.0 | 13131156 | 40015637 |

MO-6905S-0D4-210/L121

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| R4200J6DD00 | 13191606 | 13191309 | 13192802 | 11912153 | 11872009 | 11992104 | 11874807 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 11888104 | 11999307 | 13104104 | 13150602 | 13150701 | 11890100 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 13131057 | 40015637 |

MO-6905S-0E4-41H/L121

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | R4200J6ED00 | 13191606 | 13191309 | 13192802 | 11992153 | 11872009 | 11992104 | 11874807 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.0 | 11991908 | 11999307 | 13104104 | 13150602 | 13150701 | 11890100 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 4.0 | 13131156 | 40015637 |

MO-6904S-0A4-150

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 1.6 | R4200J6AC00 | 11898905 | 11887007 | 11899002 | 11876059 | 11872009 | B1507804C00 | 11792900 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 1.6 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 1.6 | 13131057 | 40015637 |

MO-6904S-0A5-150

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 1.6 | R4100J6AC00 | 11882008 | 11887007 | 11885001 | 11876059 | 11872009 | B1507804C00 | 11792900 | 13175005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 1.6 | 11888104 | 11999307 | 13104104 | 13150503 | 13150701 | 11890100 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 1.6 | 13131057 | 40015637 |

MO-6914S-BD4-307

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*3.2 | R4205J6DE00 | 11597101 | 13191309 | B1657814B0E | 11876851 | 11872009 | B150781400P | B150981400P | 12256905 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*3.2 | 12176004 | 11999307 | 13104104 | 13150503 | 13150701 | 11890308 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 2*3.2 | 13131156 | 40016841 |

MO-6914S-BE4-307

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | R4205J6EE00 | 11597101 | 13191309 | B1657814B0E | 11876851 | 11872009 | B150781400P | B150981400P | 12256905 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | 12176004 | 11999307 | 13104104 | 13150503 | 13150701 | 11890308 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 2*4 | 13131156 | 40016841 |

MO-6914S-BE6-20H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | R4305J6EE00 | 12171500 | 13191309 | 12172003 | 11876851 | 11872009 | B150781400P | B150981400P | 12256905 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | 12176103 | 11999307 | 13104104 | 13150503 | 13150701 | 11890308 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 2*4 | 13131156 | 40015637 |

MO-6914S-BE4-40H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | R4205J6EE00 | 11597101 | 13191309 | B1657814B0E | 11876851 | 11872009 | B150781400P | B150981400P | 12256905 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | 12176103 | 11999307 | 13104104 | 13150503 | 13150701 | 11890308 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 2*4 | 13131156 | 40015637 |

MO-6914S-BE6-40H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | R4305J6EE00 | 11949807 | 13191309 | 13193206 | 11876851 | 11872009 | B150781400P | B150981400P | 12256905 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | 12176103 | 11999307 | 13104104 | 13150503 | 13150701 | 11890308 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 2*4 | 13131156 | 40015637 |

MO-6914S-BE6-327/S162

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | R4305J6EE0A | 11883402 | 13191309 | 12171807 | 11879350 | 11872009 | 11974102 | B150981400P | 12256905 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | 12176004 | 11999307 | 13104104 | 13150503 | 13150701 | 11890308 | 11890001 | 13131909 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 2*4 | 13131156 | 40016841 |

MO-6914S-BE6-44H/G39/Q141

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | R4305J6EE00 | 11949807 | 13191309 | 13193206 | 12152955 | 11872009 | 12158002 | 12160305 | 12256905 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | 12176103 | 11999307 | 13104104 | 13150503 | 13150701 | 11890308 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 2*4 | 13131156 | 40015637 |

MO-6914S-BE7-44H/G02/Q141

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | R4405J6EE00 | 11883501 | 13191309 | B1657814B0F | 11879251 | 11872009 | B1507814B0B | B1509814B0B | 12256905 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | 12176103 | 11999307 | 13104104 | 13150503 | 13150701 | 11890308 | 11890001 | 13132006 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Needle width * Overedging width | P/N | P/N |

| 2*4 | 13131156 | 40015637 |

MO-6916S-DD6-300

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*3.2 | R4608J6DD00 | 11882909 | 13191408 | 12173209 | 12153755 | 12156907 | 12162202/ 12164802 |

- | 12257002 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*3.2 | 11888104 | 11999307 | 12120705 | 13104203 | 13150503 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 3.2*3.2 | 11890001 | 13132006 | 13131057 | 40015637 |

MO-6916S-DD6-3F0

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*3.2 | R4608J6DD00 | 11882909 | 13191408 | 12173209 | 12153755 | 12156907 | 12162202, 12164802 | - | 12257002 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*3.2 | 11888104 | 11999307 | 12120705 | 13104203 | 13150503 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 3.2*3.2 | 11890001 | 13132006 | 13131057 | 40015637 |

MO-6916S-DE4-300

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*4 | R4508J6ED00 | 13192406 | 13191408 | 13193602 | 12153755 | 12156907 | 12162202, 12164802 | - | 12257002 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*4 | 11888104 | 11999307 | 12120705 | 13104203 | 13150602 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 3.2*4 | 11890001 | 13132006 | 13131057 | 40015637 |

MO-6916S-DE6-300

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*4 | R4608J6ED00 | 11882909 | 13191408 | 12173209 | 12153755 | 12156907 | 12162202, 12164802 | - | 12257002 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*4 | 11888104 | 11999307 | 12120705 | 13104203 | 13150503 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 3.2*4 | 11890001 | 13132006 | 13131057 | 40015637 |

MO-6916S-FF6-300

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | R4612J6FD00 | 11884004 | 13191408 | 12173308 | 12154258 | 12157004 | 12162707, 12165304 | - | 12257507 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 11888104 | 11999307 | 12120705 | 13104203 | 13150503 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 11890001 | 13132006 | 13131057 | 40015637 |

MO-6916S-BE4-40H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | R4505J6ED00 | 11882602 | 11887304 | 13193602 | 12153953 | 12157202 | 12162400, 12165007 | - | 12275608 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2*4 | 11991908 | 11999307 | 12120705 | 13104203 | 13150602 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 2*4 | 11890001 | 13132006 | 13131156 | 40015637 |

MO-6916S-DE4-40H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*4 | R4508J6ED00 | 13192406 | 13191408 | 13193602 | 12153755 | 12156907 | 12162202/ 12164802 |

- | 12257002 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*4 | 11991908 | 11999307 | 12120705 | 13104203 | 13150602 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 3.2*4 | 11890001 | 13132006 | 13131156 | 40015637 |

MO-6916S-DE6-40H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*4 | R4608J6ED00 | 11882909 | 13191408 | 12173209 | 12153755 | 12156907 | 12162202/ 12164802 |

- | 12257002 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*4 | 11991908 | 11999307 | 12120705 | 13104203 | 13150503 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 3.2*4 | 11890001 | 13132006 | 13131156 | 40015637 |

MO-6916S-FF6-40H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | R4612J6FD00 | 11884004 | 13191408 | 12173308 | 12154258 | 12157004 | 12162707/ 12165304 |

- | 12257507 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 11991908 | 11999307 | 12120705 | 13104203 | 13150503 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 11890001 | 13132006 | 13131156 | 40015637 |

MO-6916S-DD6-500

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*3.2 | R4608J6DF00 | 11980802 | 13191408 | 12173902 | 12153755 | 12156907 | 12162202/ 12164802 |

- | 12257002 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*3.2 | 11999208 | 11999307 | 12120705 | 13104203 | 13150503 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 3.2*3.2 | 11890001 | 13132006 | 13131057 | 40015637 |

MO-6916S-FF6-500

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | R4612J6FG00 | 11883006 | 13191408 | 12173506 | 12154258 | 12157004 | 12162707/ 12165304 |

- | 12257507 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 11999208 | 11999307 | 12120705 | 13104203 | 13150503 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 11890001 | 13132006 | 13131057 | 40015637 |

MO-6916S-DF6-50H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| R4608J6FG00 | 11884400 | 13191408 | 12173506 | 12154464 | 12157103 | 12162905, 12165502 | - | 12257507 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 11991908 | 11999307 | 12120705 | 13104203 | 13150503 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 11890001 | 13132006 | 13131156 | 40015637 |

MO-6916S-FF6-50H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | R4612J6FF00 | 11883006 | 13191408 | 12173506 | 11991171 | 11991023 | 11991114/ 11991205 |

- | 12257507 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 11991908 | 11999307 | 12120705 | 13104203 | 13150503 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 11890001 | 13132006 | 13131156 | 40015637 |

MO-6916S-FH6-50H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*6.4 | R4612J6HG00 | 11883006 | 13191408 | 12173506 | 11991171 | 11991023 | 11991114/ 11991205 |

- | 12257507 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*6.4 | 11991908 | 11999307 | 12120705 | 13104203 | 13150503 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 4.8*6.4 | 11890001 | 13132006 | 13131156 | 40015637 |

MO-6916S-FF6-60H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | R4612J6FK00 | 12171104 | 13191408 | 12174207 | 12155552 | 12157319 | 12164000/ 12165908 |

- | 12150702 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 12176202 | 11999802 | 12120705 | 13104203 | 12004909 | 11566502 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 11890001 | 13132006 | 13131156 | 40015637 |

MO-6916S-FH6-60H

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*6.4 | R4612J6HK00 | 12171104 | 13191408 | 12174207 | 12155552 | 12157319 | 12164000/ 12165908 |

- | 12150702 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*6.4 | 12176202 | 11999802 | 12120705 | 13104203 | 12004909 | 11566502 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 4.8*6.4 | 11890001 | 13132006 | 13131156 | 40015637 |

MO-6916S-FF6-42H/S159

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | R4612J6FD0A | 12170908 | 13191408 | 12174504 | 12154852 | 11991023 | 12163309/ 11991205 |

- | 12257507 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 11991908 | 11999307 | 12120705 | 13104203 | 13150602 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 11890001 | 13132006 | 13131156 | 40015637 |

MO-6916S-DE4-42H/S161

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | STITCH TONGUE | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

- |  |

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*4 | R4508J6ED0B | 12170700 | 13191408 | 12172904 | 12154654 | 12157103 | 12163101/ 12165502 |

- | 12257002 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 3.2*4 | 11991908 | 11999307 | 12120705 | 13104203 | 13150602 | 13150701 | 12015301 | 12015400 | 12177903 |

| Guage | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|

| Figure |  |

|

|

|

| Needle width * Overedging width | P/N | P/N | P/N | P/N |

| 3.2*4 | 11890001 | 13132006 | 13131156 | 40015637 |