Computer-controlled, Eyelet Buttonholing Machine with Trimmer for Needle and Looper Thread with Gimp

The world's first machine that incorporating an active tension mechanism.

(computer-controlled thread tension mechanism)

Product features

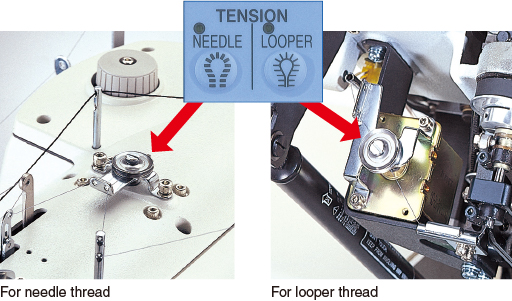

AN ACTIVE TENSION MECHANISM (COMPUTER-CONTROLLED THREAD TENSION MECHANISM) THAT ELECTRONICALLY CONTROLS THE NEEDLE AND LOOPER THREAD TENSIONSTHE FIRST IN THE WORLD!

Needle and looper thread tensions can be digitally established on the operation panel according to sewing conditions.

Data can be registered on a pattern-by-pattern basis to easily reproduce the same sewing conditions.

Using conventional machines, it's often quite difficult to reproduce the same sewing conditions. This machine does it with ease. With this capability, the MEB-3200 responds immediately to material changes, significantly reducing the time required for setup changes or adjustments. The machine also ensures the consistent production of high-quality seams.

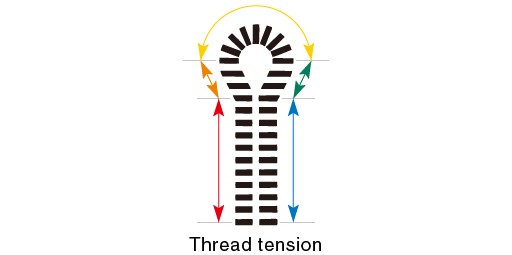

Thread tensions can be separately established for various sections of a buttonhole such as eyelet sections and parallel sectionsACTIVE TENSION

- The machine promises high-quality seams by smoothly responding to changes in stitch formation and allowing the operator to set a separate thread tension for the bartacking sections of buttonholes.

- Thread tensions for the beginning and end of sewing can also be separately established. This helps prevent loose stitches or slip-off or raveling of thread at the beginning of sewing.

Threading work can be more easilyACTIVE TENSION

Since fewer parts need to be threaded, the machine can be threaded more quickly and easily than conventional buttonholing machines.

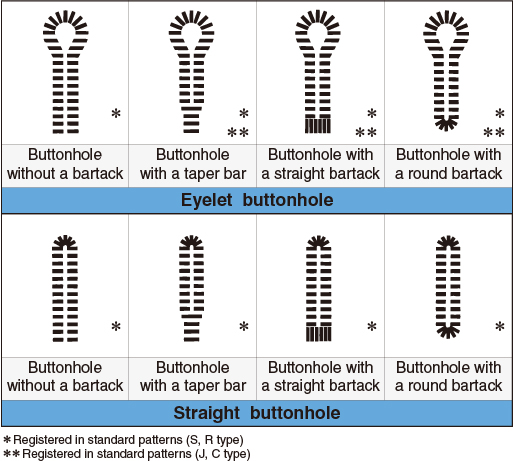

HIGHER FLEXIBILITY

Thanks to the computer control, many different eyelet shapes and straight buttonhole shapes can be selected or established on the operation panel.

The machine is provided as standard with 10 different stitching shape patterns. As many as 89 different patterns can be stored in memory and selected.

EASY-TO-OPERATE MULTI-FUNCTIONAL OPERATION PANEL

All pieces of data on sewing specifications can be established/selected on the operation panel.

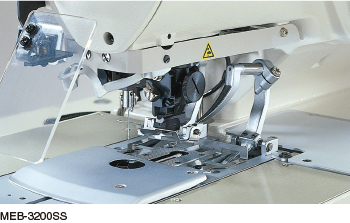

Newly developed machine head that efficiently sews longitudinal buttonholes

- JUKI has newly developed a machine head with a shallow recess. For the efficient sewing of longitudinal buttonholing.

*Use MEB-3200RS for combined use for lateral and longitudinal buttonholing. - The machine head has a wider space under the work clamps to permit easy placement of a sewing product, thereby improving workability.

- The semi-sunken machine head promises easy placement and smooth handling of sewing products.

- The amount of material opened can be easily adjusted using the screw mounted outside the machine head.

- JUKI has newly developed a machine head with a shallow recess. For the efficient sewing of longitudinal buttonholing.

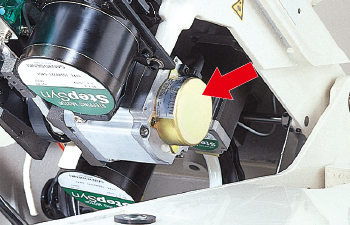

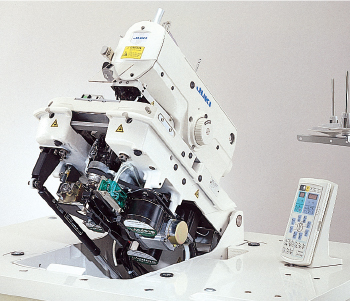

Direct-drive motor is adopted

The machine has adopted a direct-drive method that connects a compact AC servomotor directly to the hook-driving shaft. The quick startup and increased stopping accuracy obtained as a results guarantees outstanding responsiveness.

In addition, the direct-drive motor does not use a V-belt to reduce power consumption.

MEB-3200SS

M, provided with multi-cutting deviceSUBCLASS

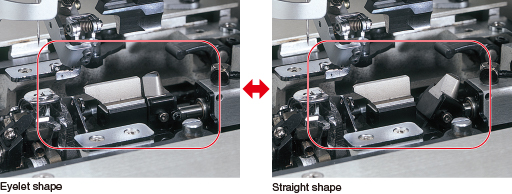

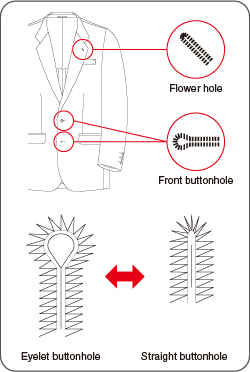

M, provided with multi-cutting deviceSUBCLASS- The multi-cutting device incorporates a separate cloth cutting knife with two sections of blade --- one intended for the eyelet sections of buttonholes and one intended for straight sections. When sewing men's wear, the machine can sew eyelet buttonholes on a front body and straight buttonholes on a lapel without changing the knife. Conventionally, two different types of buttonholing machines are required for these processes. By performing two different kinds of buttonholing, the MEB-3200

M halves the time required for the setup procedure, including color thread changing. The end result is increased productivity.

M halves the time required for the setup procedure, including color thread changing. The end result is increased productivity. - By dropping the knife two or more times per cycle, the machine can sew buttonholes of various sizes without changing the knife guard (18mm to 38mm for eyelet buttonholes and 10mm to 38mm for straight buttonholes). The machine is best suited for small-lot production of ladies' wear subject to frequent design changes.

The machine is equipped as standard with a needle thread clamp device.

- The multi-cutting device incorporates a separate cloth cutting knife with two sections of blade --- one intended for the eyelet sections of buttonholes and one intended for straight sections. When sewing men's wear, the machine can sew eyelet buttonholes on a front body and straight buttonholes on a lapel without changing the knife. Conventionally, two different types of buttonholing machines are required for these processes. By performing two different kinds of buttonholing, the MEB-3200

MEB-3200

A, provided with needlle tthrread cllamp deviceSUBCLASS

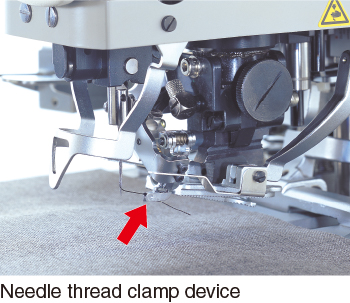

A, provided with needlle tthrread cllamp deviceSUBCLASS- The needle thread clamp device eliminates the thread securing procedure by tucking the needle thread in the finished seams.

- The needle thread clamp device retains the needle thread to ensure neat seam formation from the very first stitch.

*The needle thread clamp device can be retrofitted to the machine. Optional part: Part No.: 320-24481

Basic performance

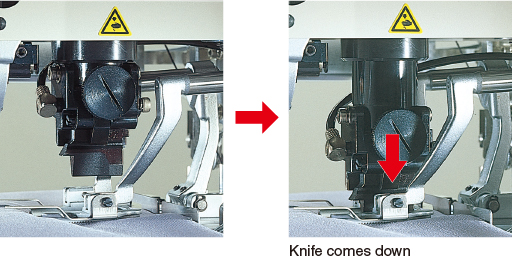

Vertically driven cloth cutting knife controlled by a stepping motor

- The knife is controlled by a stepping motor. This enables easy adjustment of the knife pressure on the operation panel to suit the material to be used, thereby preventing irregular cutting.

- Data on knife pressure can be registered on pattern-by-pattern basis to establish the best-suited knife pressure according to sewing specifications. Adequate knife pressure improves durability of cloth-cutting knife and knife guard.

- Selection between the cut-before knife and cut-after knife can be made on the operation panel.

- The stepping-motor-controlled cloth-cutting knife is free from the troubles likely to affect air-driven knives, including dull cutting and the breakage of parts such as the knife-driving arm.

In addition, a large-capacity compressor is no longer required since the machine uses less compressed air.

Separately driven right and left work clamps

The right and left work clamps are separately driven by independent air cylinders. With this mechanism, the work clamps reliably clamp materials of different thicknesses to prevent the materials from flopping.

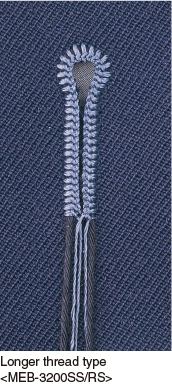

Reliable overall thread-trimming mechanism

The MEB-3200SS/RS for men's and ladies' wear cuts needle threads, looper threads and gimps to leave longer threads on the material. The thread trimmer cuts the thread on the material to lengths that allow the machine to easily retain the thread ends. This facilitates the subsequent bartacking process.

Excellent maintainability

- The computer controlled design eliminates most of the complicated mechanisms. This dramatically improves maintainability.

- The machine head is supported by a gas-spring that makes it easy to raise for smoother cleaning and threading.

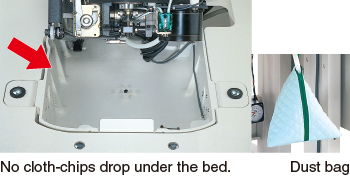

Improvements of working environment

- Designed without a clutch mechanism or stop-motion mechanism, the machine produces no stop-motion noise.

- The machine automatically reclaims cloth chips after cloth cutting action to keep the working environment cleaner.

Specification

| Model name | MEB-3200SS | MEB-3200RS | MEB-3200JS | MEB-3200CS | MEB-3200TS |

|---|---|---|---|---|---|

| Application | Men's and ladies' wear | Combined use for lateral and longitudinal buttonholing: for men's and ladies' wear | Jeans | Cotton pants and working wear | Trousers |

| Thread trimming style | Longer remaining thread | Shorter remaining thread | Shorter thread cutting without gimp | ||

| Stitch system | 1-needle, double chainstitch (with gimp) | 1-needle, double chainstitch (without gimp) | |||

| Max. sewing speed | 400~2,200sti/min*1 (100sti/min*1 step) | ||||

| Sewing length | 10~38mm (with thread trimmer) 10~50mm (in case looper thread trimming device is removed)*2 |

Work clamp type S 16~24 (26)mm: optional Work clamp type M 24~32 (34)mm: standard Work clamp type L 32~40 (42)mm: optional |

Work clamp type S 16~24 (26)mm: standard Work clamp type M 24~32 (34)mm: optional Work clamp type L 32~40 (42)mm: optional |

10~34mm Compensating work clamp S, 24mm for eyelet buttonholes: standard |

|

| Needle throwing width (at the time of delivery) |

2.0~3.2mm*2 | 2.6~4.0mm*3 | 2.0~3.2mm*3 | 2.0~3.2mm | |

| (2.3mm) | (2.5mm) | (2.5mm) | (2.3mm) | ||

| Taper bar length | 0mm, 3~15mm | ||||

| Work clamp height | 13mm (max. 16mm) | ||||

| Method for changing stitch shape | By selecting a program | ||||

| Buttonhole cutting method | By cut-before knife or cut-after or without buttonhole cutting | ||||

| Feed system | Intermittent feed by stepping motor | ||||

| Cloth cutting knife drive system | Vertically driven by stepping motor | ||||

| Needle (at the time of delivery) |

DO×558 (Nm100) Nm90~Nm110 |

DO×558 (Nm120) Nm110~Nm120 |

DO×558 (Nm110) Nm110~Nm130 |

DO×558 (Nm100) Nm100~Nm110 |

|

| Lubrication | Automatic (looper and spreader: by an oiler) | ||||

| Lubricating oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) | ||||

| Compressed air and air consumption | 0.5MPa 6dm³/min (ANR) [8cycle/min] | ||||

| Power requirement and power consumption | Single-/3-phase, 550VA | ||||

| Dimensions | 1,060mm (W)×790mm (D)×1,230mm (H) | ||||

| Total weight | 185kg | ||||

*1 "sti/min" stands for "Stitches per Minute."

*2 When the sewing length of 38~50mm without thread trimmer is selected, the work clamp can be provided by placing special order.Please use the Multi-cutting device when you cut the cloth.

*3 By selecting the left looper and left spreader, the range of stitch bite can be changed to 2.6~4.0mm from 2.0~3.2mm (TS model is excluded)

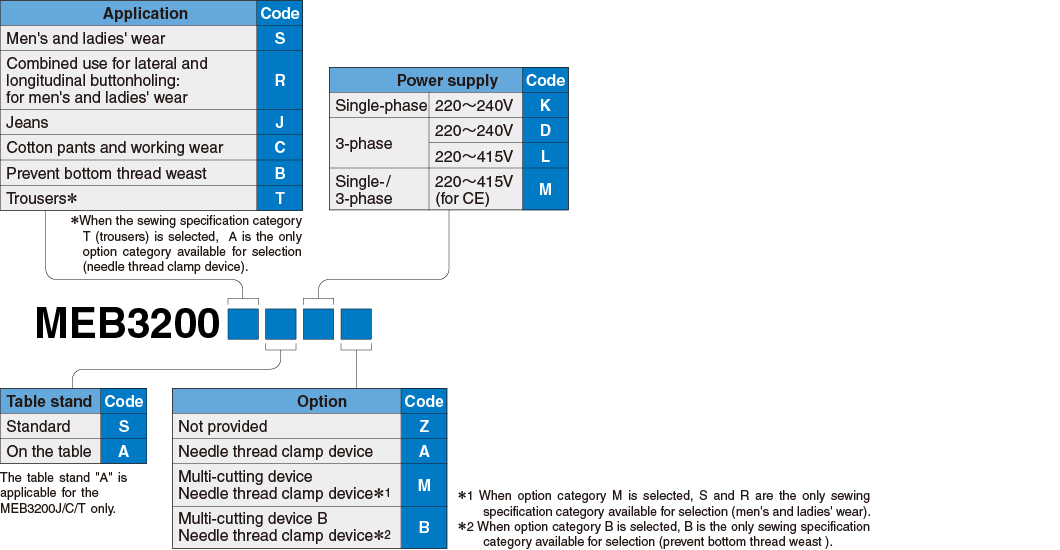

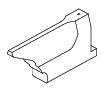

When you place orders

Gauge

MEB-3200SS

MEB-3200RS

MEB-3200JS

MEB-3200CS

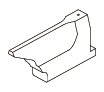

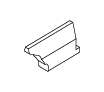

| Item | KNIFE SUPPORT | |||

|---|---|---|---|---|

| Application | For eyelet buttonhole | For decorative buttonhole | For hard eyelet buttonhole | |

| Figure |  |

|

|

|

| Length of knife(mm) | P/N | P/N | P/N | P/N |

| 40 | - | 14042501 | - | |

| 38 | 32062101 | - | 32067209 | |

| 36 | 32062200 | 32064404 | 32067308 | |

| 34 | 32062309 | 32064503 | 32067407 | |

| 32 | 32062408 | 14042600 | 32067506 | |

| 30 | 32062507 | 32064602 | 32067605 | |

| 28 | 32062606 | 32064701 | 32067704 | |

| 26 | 32062705 | 14042808 | 32067803 | |

| 24 | 32062804 | 32064800 | 32067902 | |

| 22 | 32062903 | 14042907 | 32068009 | |

| 20 | 32063000 | 32064909 | 32068108 | |

| 18 | 32063109 | 32065005 | 32068207 | |

| 16 | 32063208 | 14043103 | 32068306 | |

| 14 | 32063307 | 32065104 | 32068405 | |

| 12 | 32063406 | 32065203 | 32068504 | |

| 10 | 32063505 | 14043301 | 32068603 | |

| Item | CLOTH CUTTING KNIFE | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Application | For eyelet buttonhole | |||||||||

| Figure |  |

|

|

|

|

|

|

|

|

|

| P/N | 32063604 | 32063802 | 32063901 | 32064008 | 32064107 | 32064206 | 32064305 | 32066904 | 14041206 | 32063703 |

| Mark | 3S | 5 | 1S | 1M | 5 | 5S | 5M | 6 | 3 | 3M |

| Item | CLOTH CUTTING KNIFE | ||

|---|---|---|---|

| Application | For decorative buttonhole | ||

| Figure |  |

|

|

| P/N | 32065302 | 32065401 | 14041404 |

| Mark | OS | OM | O |

| Item | WORK CLAMP_LEFT | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Application | For eyelet buttonhole | For eyelet buttonhole | For decorative buttonhole | For eyelet buttonhole | For eyelet buttonhole | For eyelet buttonhole | For eyelet buttonhole | For eyelet buttonhole | For eyelet buttonhole |

| mm | 32 | 22 | 40 | 40 | 32 | 22 | 40 | 32 | 22 |

| Figure |  |

|

|

|

|

|

|

|

|

| P/N | 14059604 | 14059802 | 14010102 | 14010102 | 32028706 | 32028300 | 14058903 | 40035239 | 40039844 |

| Item | WORK CLAMP_RIGHT | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Application | For eyelet buttonhole | For eyelet buttonhole | For decorative buttonhole | For eyelet buttonhole | For eyelet buttonhole | For eyelet buttonhole | For eyelet buttonhole | For eyelet buttonhole | For eyelet buttonhole |

| mm | 32 | 22 | 40 | 40 | 32 | 22 | 40 | 32 | 22 |

| Figure |  |

|

|

|

|

|

|

|

|

| P/N | 14059505 | 14059703 | 14013809 | 14010003 | 32028607 | 32028201 | 14058804 | 40035238 | 40039843 |