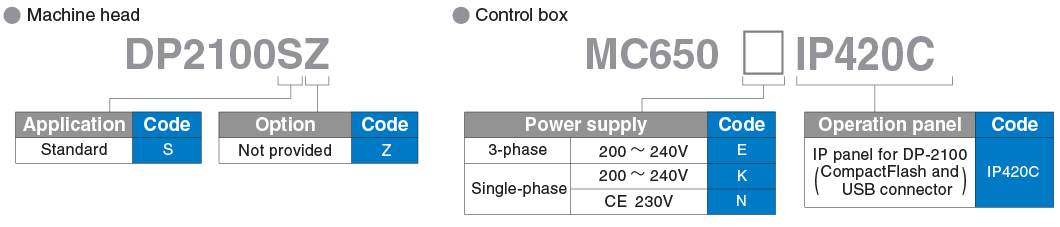

Computer-controlled, Dry-head, Lockstitch Sleeve

Setting Machine with Multi-programming Device

Easier operation, Higher quality.

Product features

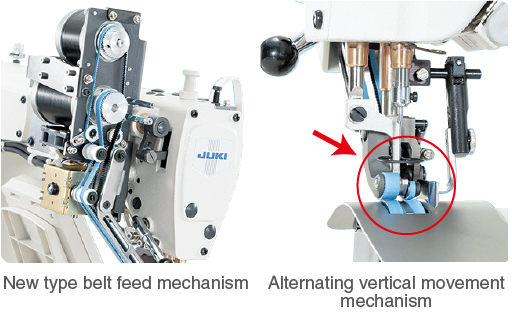

An excellent new type belt feed mechanism

- Thanks to JUKI's unique right-and-left independent drive system of the top feed belt, right and left feed amounts can be adjusted separately. This prevents the material from slipping out of position, thereby sewing sleeves with a consistent seam allowance.

- The machine comes provided with a mechanism for moving the belt feed and intermediate presser up and down alternately, enabling it to eliminate tucks produced at the sleep cap as well as irregular puckering produced in the neighborhood of the sleeve cap.

- By introducing the belt feed, the machine reduces scratches to the material made by the feed.

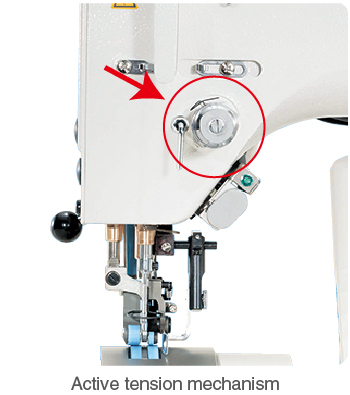

The machine has solved the problems of conventional sleeve-attaching machines

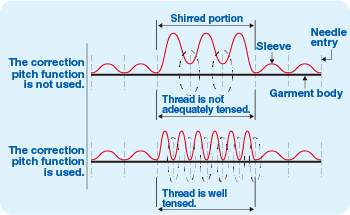

The introduction of active-tension enables the separate setting of suitable thread tensions for sewing sleeves on a portion-by-portion basis. This prevents an inadequate thread tension at a portion where the shirring amount is large or an excessive thread tension at a portion where the shirring amount is small. In addition, specified tension settings can be stored in the memory on a pattern-by-pattern basis and can be reproduced with ease.

Color panel, IP-420C, with upgraded operability

- Since the machine comes with a touch-sensitive operation panel with a color LCD, data required for sewing, such as the shirring amount, needle thread tension and stitch pitch can be entered with ease.

- In addition to the CompactFlash TM, the machine is provided as standard with a USB connector. As a result, the use of a USB flash drive or card reader enables the storage and transmission of sewing data by means of various kinds of media (such as a floppy disk, SmartMedia, CompactFlash and SD card) to enable sewing using the same sewing data among sewing machines in a plant or among subcontract plants.

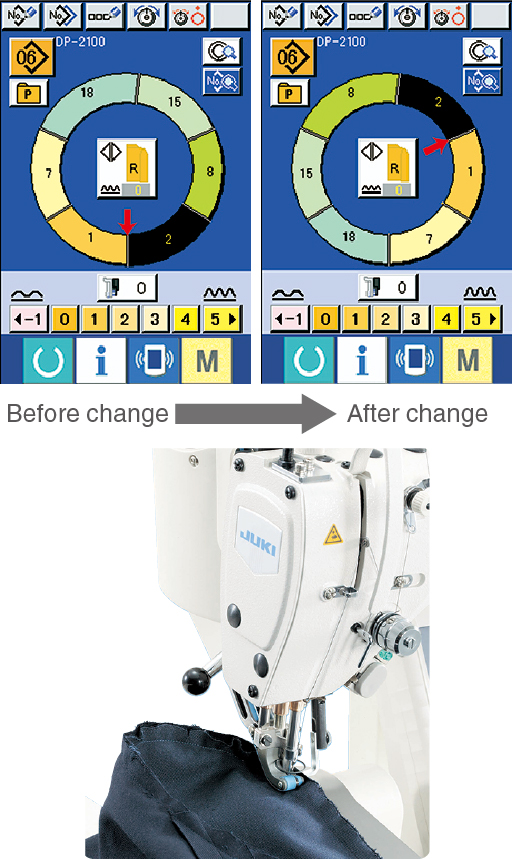

- The operating screen gives a graphic display of an armhole. The operator can, therefore, easily confirm the portion to be sewn and enter/edit data.

Operation mode selection is enabled

The operation mode of a single machine can be changed over between manual, semi-auto and full-auto according to the ease of use for each operator.

Many different data input features:

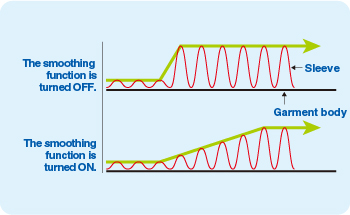

Smoothing functionThe machine prevents an abrupt change in the shirring amount at the sewing-step changing point by utilizing a smoothing function. This upgrades the finished quality of the seams.

Many different data input features:

Correction pitch setting functionThe stitch pitch can be changed on a portion-by-portion basis. Seam grinning can be prevented by decreasing the stitch length at a portion where the shirring amount is large.

Many different data input features:

The starting position of the shirring program can be changedIt is possible to change the starting position of the program entered. This enables the armhole display shown on the LCD to bear a close resemblance to the armholes of actual sewing products.

Many different data input features

In addition, the machine comes provided with various data inputting features, such as teaching, grading and mirroring for the easy programming of sewing data and for improved operating efficiency.

Basic performance

Dry-head sleeve sewing machine

The DP-2100 is the world's first sleeve sewing machine that has adopted the dry-head technology, which does not need oiling. The machine protects the sleeve sewing process, which determines the quality of men's and ladies' garments, from troubles such as oil stains. No need for lubrication facilitates maintenance.

Highly-reliable direct-drive system

The machine comes with the direct-drive system, in which a compact AC servomotor is directly joined to the main shaft. It offers a quick startup, increased stopping accuracy and excellent responsiveness.

Increased lift of the presser foot

An increase in the lift of the presser foot facilitates placement of the material under the presser foot as well as the removal of a finished portion.

Stitch length is increased

The maximum stitch length has been increased to 6 mm. With this large stitch length, an adequate shirring amount is ensured even when a heavy-weight material is used.

Specification

| Model name | DP-2100 | ||

|---|---|---|---|

| Max. sewing speed *1 | 3,500sti/min (feed pitch 1.5~4.0mm) | ||

| Feed system | Intermittent belt feed with the direct-driven stepping motor | ||

| Stitch length(both top and bottom) | 1.5~6.0mm | ||

| Needle bar stroke | 30.7mm | ||

| Needle | DP×17 #10~#14 | ||

| Thread take-up | Link type | ||

| Hook | Horizontal-axis full-rotary non-lubricated hook | ||

| Lift of the presser foot | By hand: 5.5mm, Auto: 10mm | ||

| Amount of the alternating vertical movement of the presser foot and walking foot | Max. 3.5mm | ||

| Adjustment of amount of the alternating vertical movement of the presser foot and walking foot | Adjustment of stopping position in slot | ||

| Bottom and variable top feed stitch adjusting method | Data entry through the operation panel, stepping motor | ||

| Minimum resolution of bottom and variable top feed adjustment | 0.1mm | ||

| Number of programs that can be input | 99 programs | ||

| Number of steps that can be input (for one program) | 30 steps | ||

| Lubrication | No lubrication | ||

| Needle thread tension | Active tension (electric thread tension control system) | ||

| Right and left alternating sewing | Possible | ||

| Automatic reverse feed function | Provided as standard | ||

| Soft-start function | Provided as standard | ||

| Auto-lifter | Provided as standard | ||

| Power requirement / Power consumption | Single-phase 200~240V, 3-phase 200~240V / 560VA | ||

| Total weight | 106kg | ||

*1 The maximum sewing speed is limited by the amount of the alternating vertical movement of the walking foot and presser foot and stitch length.

Programming device performance

| Operation mode | Manual | |

| Semi-auto | ||

| Full-auto | ||

| Detailed data on steps stored in memory | Shirring amount | |

| Needle thread tension | ||

| Number of stitches | ||

| Stitch pitch | ||

| Monitoring of shirring amounts and sewing positions | ||

| Teaching function | ||

| Grading function | ||

| Mirroring function | ||

| Program starting position changing | ||

When you place orders