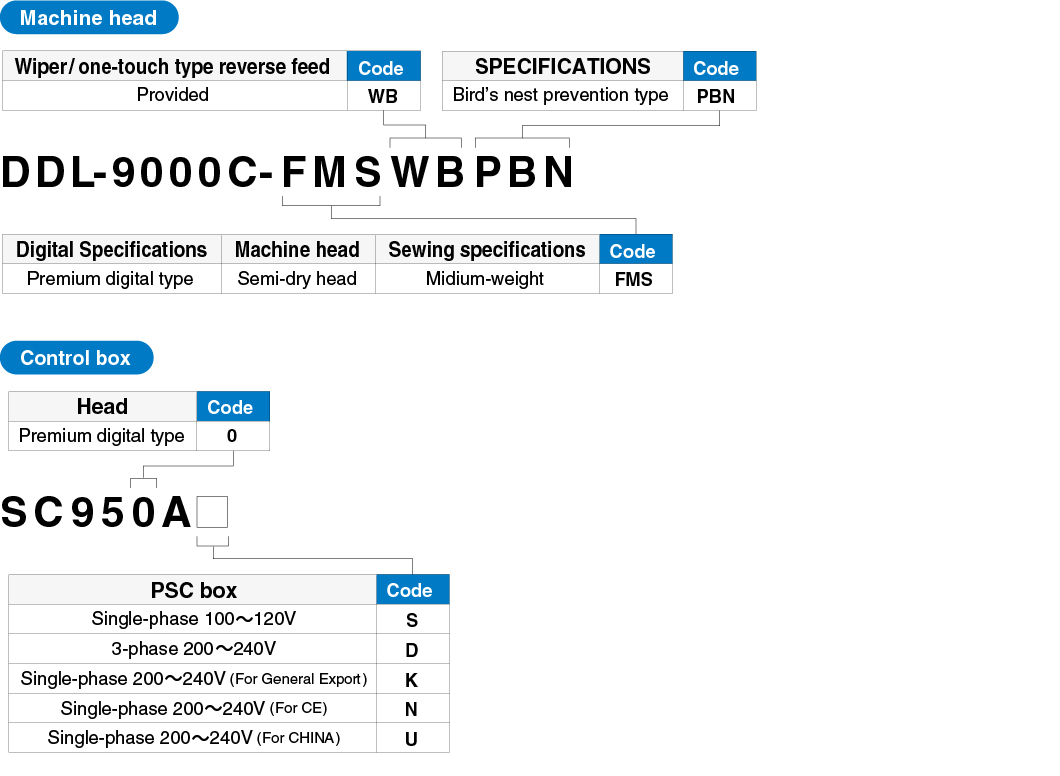

Semi-dry head, Direct-drive, 1-needle Lockstitch Sewing System with Automatic Thread Trimmer (Bird’s nest prevention type)

DDL-9000C/PBN digitalizes the machine adjustment used to be handled based on personal hunches and experience. The machine comes with bird’s nest prevention that commits to “seam quality”. The newly-developed model totally eliminates bird's nests at the starting of sewing, which have been a conventionally inevitable factor when using machines with a thread trimmer. The length of thread remaining at the end of sewing is shortened.

Product features

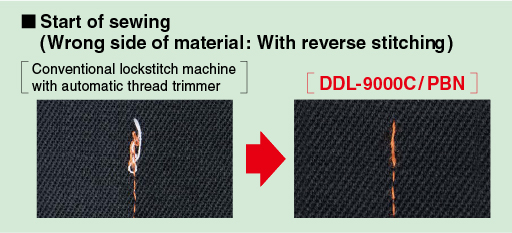

The machine eliminates the “bird’s nest” at the starting of sewing

The machine starts sewing with the needle thread clamped and held with its unique air & ball type clamp. High-quality seams, thereby, are promised without leaving bird’s nests (thread tangling) on the wrong side of the material.

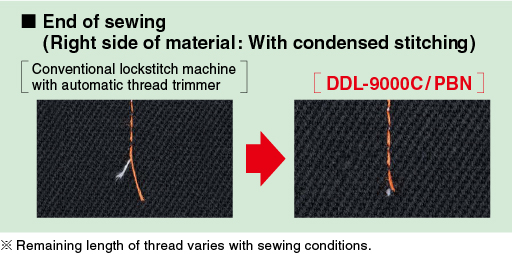

Only 3 mm long thread is left on the material at the end of sewing

The machine adopts a new thread trimming method where the newly-developed thread trimming mechanism trims the thread directly below the throat plate while the last stitch (or two stitches) at the end of sewing is (are) sewn with a smaller stitch length using condensation stitching.

As a result, the length of thread remaining on the material is shortened, thereby eliminating thread nipping work.

Management of sewing performance and sewing machine by the utilization of IoT

(Internet of Things)Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially-available Android tablet in contactless mode. This enables quick check for uniform settings as well as confirmation of conditions of sewing machines in a sewing line, thereby facilitating setup changes.

The operation panel is also provided as standard with a USB port.

Data management and software update can be carried out with ease using a USB thumb drive.Data items of sewing can be numerically managed to ensure “stable quality” and “reduction in time required for setup changes”. Quantified sewing data can be externally taken from the sewing machine using an Android tablet or USB thumb drive.

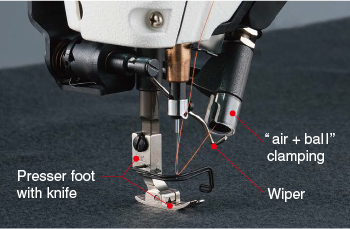

Reliable grasping of thread by the clamping method

The sewing machine has adopted the thread clamping system that pneumatically draws the needle thread which remains after thread trimming and clamps it with the ball. As a result, the needle thread is clamped without fail while requiring no additional adjustment even when the type and count of thread is changed.

JUKI’s unique “air + ball” clamping system

Not only the reliable thread clamping mechanism but also downsized needle-surrounding portion of the machine head are achieved by the thread clamp mechanism that combines the air cylinder with the ball. Due to its strong thread clamping force, the needle thread can also be trimmed without fail.

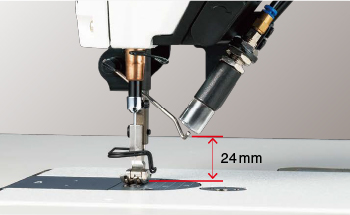

Operability is given priority with respect to the area that surrounds the presser foot

The thread clamp device and the wiper are located as far as possible from the needle entry area. This simple arrangement of the area around the presser foot allows the operator to handle the material with ease and ensures smooth operation.

This sewing machine can also be used as the standard sewing machine provided with the thread trimmer

For sewing processes that do not require the “bird's nest preventing function”, the sewing machine can be used as the standard sewing machine with the thread trimmer by disabling the air cylinder through the operation panel.

Basic performance

Commitment to seam quality “Reverse-feed stitching function by means of the reverse feed lever” is provided as standard

The operator carries out fine adjustment of correction sewing (within the stitch length of 1 pitch) using the reverse feed lever, thereby achieving “further improved seam quality”.

LED light

The LED light illuminates the needle entry area in the just-under direction from the right and left sides of the needle bar. In comparison with the single-direction illumination, this LED light helps the operator carry out sewing more easily.

Illuminance of the LED light is adjustable in five levels. It can also be used as an auxiliary lamp for working.

Specification

| Model name | DDL-9000C-FMS/PBN |

|---|---|

| Type | Premium Digital Type |

| Application | Medium-weight |

| Lubrication system | Semi-dry |

| Max. sewing speed | 4,000sti/min* |

| Max. stitch length | 4mm |

| Thread trimming method | Double-edge rotary system |

| Lift of the presser foot | Auto: 1st stage 5.0 mm (*0.1~8.5mm), 2nd stage 8.5 mm (*8.5mm~13.5mm) *Adjustable on the operation panel |

| Needle | DB×1, DP×5 (Standard #11) #9~18 (Nm65~110) |

| Lubricating oil | JUKI New Defrix Oil No. 1 or JUKI CORPORATION GENUINE OIL 7 (equivalent to ISO VG7) |

*sti/min is the abbreviation for "stitches per minute"

When you place orders