Machine operation management system

Future-oriented IoT (Internet of Things) enables real-time visualization of operation status of the production site!

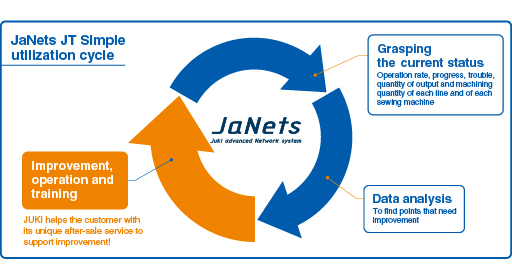

JaNets is JUKI-provided IoT service to help customers increase productivity.

Product overview

Effects/benefits

JaNets achieves reduction in management man-hours and improvement of productivity at the same time

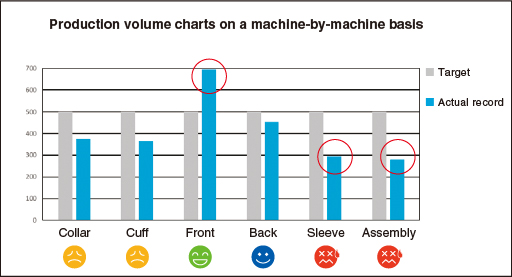

Real-time comparison of production volume in processes facilitates the consideration of measures for improving productivity.

Conventionally, productivity of a factory is measured with the number of finished products or the production volume on a process-by-process is reflected on the operators' wages. It is difficult to use those discretely grasped productivity-related figures for improvement of productivity.

Easy comparison of production volumes on a process-by-process basis by means of charts allows at-a-glance identification of bottleneck processes that disrupt the smooth flow of the production line, thereby contributing to quick consideration of improvement measures.

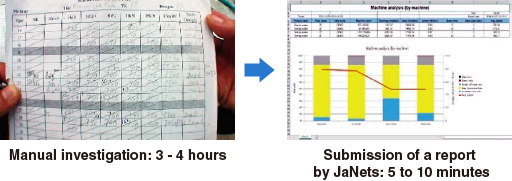

Information for the purpose of analysis can also be collected and analyzed with ease

Data on sewing machine operations are automatically accumulated during production. This means reports can be prepared easily without additional investigation.

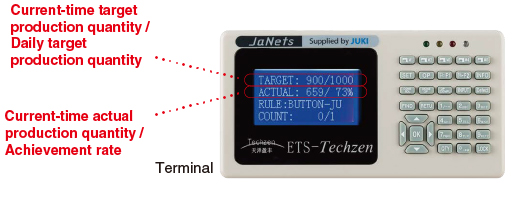

Change in the mind-set of operators

JaNets provides the operator with both the daily target production quantity and the real-time number of pieces produced, thereby helping improve the operator's motivation.

Product features

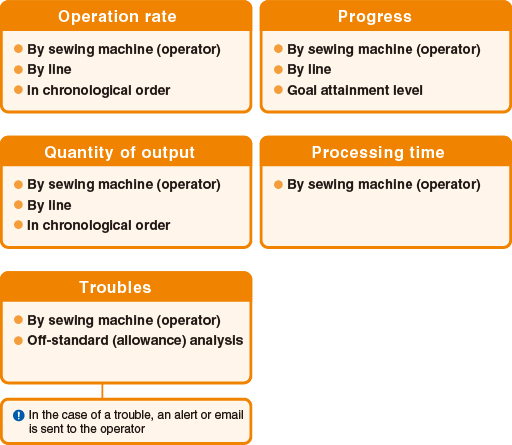

Visualization with the JaNets!

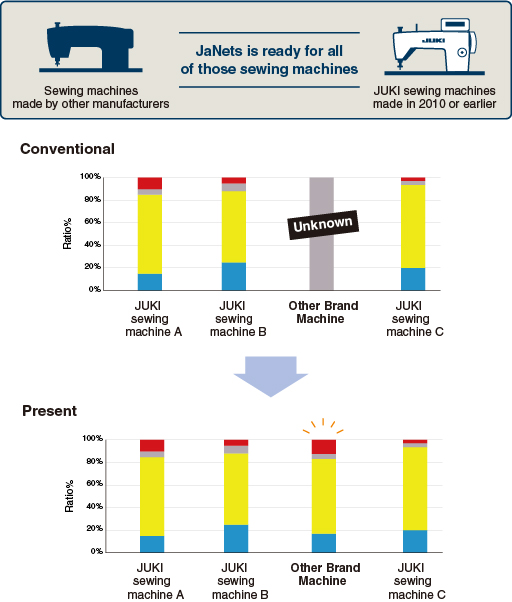

Accurate and real-time information on all of the sewing machines* in use becomes visible from remote places.

*Including the sewing machines made by JUKI and other manufacturers

Connection with the JaNets!

The use of the JaNets leads to various improvements that contribute to increased productivity of each operator.

Security is provided after the introduction of the JaNets !

JUKI’s unique after-sale service to provide continued support for improvementJUKI support the JaNets system and train your factory personnel in charge.

Remote training program

JUKI has the remote training programs on production management, maintenance, diagnosis, etc. for customers’ personnel. Please contact JUKI for details.

- How to reduce the quantity in progress?

- What is the best quantity in progress?

- How to reduce wastes in the factory?

Site remediation support by a PE staff

Our PE staff firstly checks the production line in the customer’s factory to find where the waste is. Then, the staff supports improvement activities of the customer.

Remote follow-up service

JUKI provides follow-up service in the case of a trouble to remotely check the customer’s system.

Provision of the latest software that responds to the customer’s needs

The JaNets is an evolving machine operation management system. Newly developed functions are periodically added to give new added value to the JaNets installed in the customer’s factory.

Basic performance

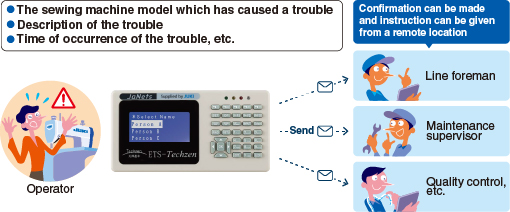

Information on troubles can be shared quickly

Operators are able to send information to administratorsThe operator is allowed to provide information on troubles to administrators by e-mail using the terminal.

Destination address of the e-mail can be selected from several ones such as a maintenance supervisor.

Information on the sewing machines of other manufacturers can also be acquired!

The JaNets enables collective management of all of the sewing machines in the factoryBy attaching the sensor, data can be acquired from sewing machines made by other companies and old JUKI sewing machines before 2010.