1-needle, Top & Bottom Feed, Lockstitch Machine

The basic sewing machine equipped to sew heavy-weight materials promises consistent seam quality and outstanding operability.

Product features

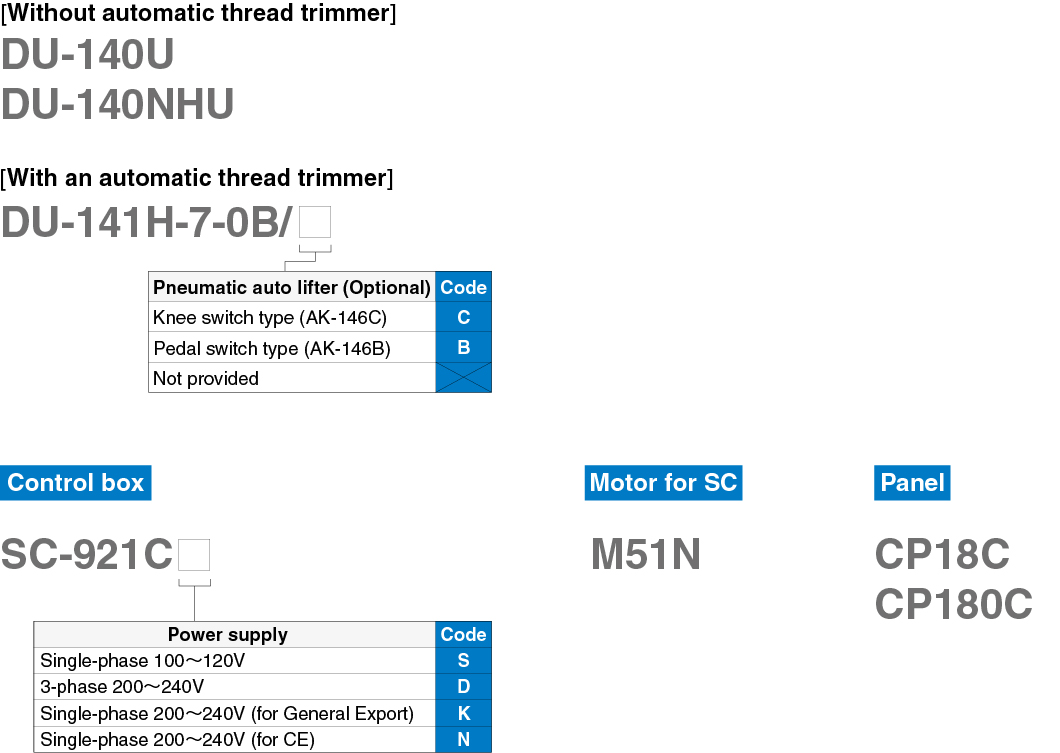

Higher lift of the presser foot

The presser foot can be pushed up as high as 15 mm using the knee lifter. This feature is especially effective for sewing processes that require a higher lift of the presser foot such as piping, binding-tape sewing, and sponge-cloth sewing.

Maximum stitch length of 9 mm

The stitch length is adjusted in the range of 0 to 9 mm both in the normal and reverse directions by operating the stitch dial. This feature allows the machine to be used in wider applications such as decorative stitching, which requires a larger pitch and sewing of tent sheets.

The reverse-feed sewing length is also adjustable.

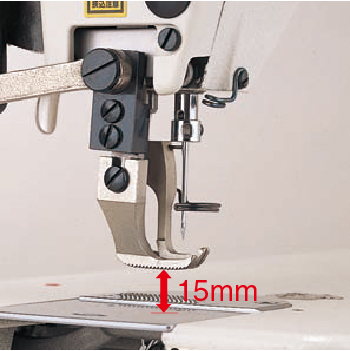

Frequency of bobbin thread replacement has been reduced

(DU-141NH, DU-141H-7)The machine incorporates a horizontal-axis, double-capacity hook. By reducing the frequency of bobbin thread replacement, this type of hook further upgrades efficiency in operation.

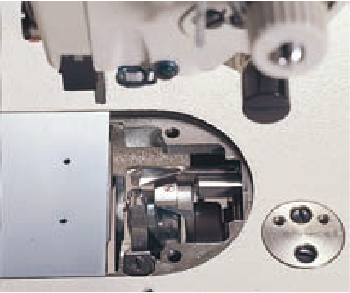

Thread trimmer cuts a thread sharp without fail

(DU-141H-7)The knife is driven by a thread trimming cam ideal for cutting thick threads at a sharp angle.

Automatic reverse feed function

(DU-141H-7)Reverse-feed stitching operation can be started simply by pressing the one-touch-type reverse-feed button.

Furthermore, if a suspended ruler is attached on the machine or a 3-dimensional sewing product is sewn, the button can be shifted upward to prevent interruption.

Newly developed control box/Compact-size servomotor (DU-141H-7)

The new model control box SC-921C has been newly developed.

The control box is resistant to voltage fluctuations, noise and vibration.

The new model control box is provided with an energy-saving mode for the first time in a control box for sewing machines.

In addition, the current DU-141H-7 is lavished with the latest energy-saving technologies, including the adoption of the latest compact servomotor M51N, to be more friendly to theenvironment, as well as to provide the power reducing effect and to increase productivity.The operation panel CP18C, CP180C can be selected according to the process

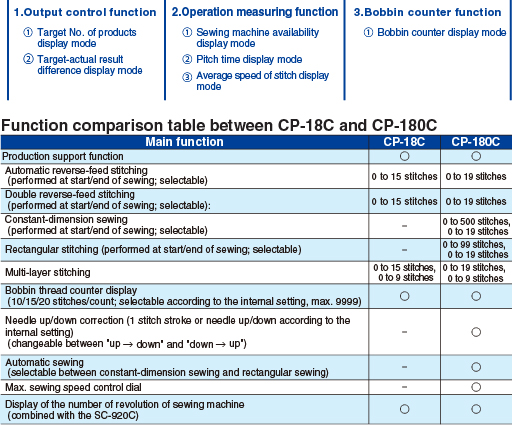

(DU-141H-7)Two different operation panels, the CP-18C and CP-180C are applicable to the DU-141H-7.

Both operation panels are provided with the production support function.

The production support function actually consists of three different functions (six different modes).

Basic performance

Consistent seam quality

With its unique thread take-up mechanism, feed mechanism, and hook, the machine feeds difficult-to-feed materials and multi-layered portions of material with great precision, thereby producing beautifully finished seams of consistent quality.

Specification

| Model name | DU-140 | DU-141NH | DU-141H-7 |

|---|---|---|---|

| Type | - | With an automatic thread trimmer | |

| Max. sewing speed | 2,000 rpm | ||

| Max. stitch length | 9 mm (Normal/Reverse feed) | ||

| Needle bar stroke | 35 mm | 37 mm | |

| Lift of the presser foot | By knee lifter: 15 mm/By hand lifter: 7 mm | By knee lifter: 15 mm/By hand lifter: 6 mm | |

| Thread take-up | Link type | ||

| Alternating vertical movement | 2~5 mm | ||

| Hook | Horizontal-axis full-rotary hook | Horizontal-axis full-rotary double-capacity hook | |

| Needle | DB×1 (DP×17) #14~#23 (Standard #21) | DB×1 (DP×17) #20~#23 (Standard #21) | |

| Thread | #40~#8 (Japanese yarn count) | ||

| Lubrication | Automatic | ||

| Free space for sewing | 265 mm | 270 mm | |

| Bed size | 477 mm×178 mm | ||

| Weight of the machine head | 32 kg | 34 kg | |

| Automatic reverse feed function | - | Provided as standard | |

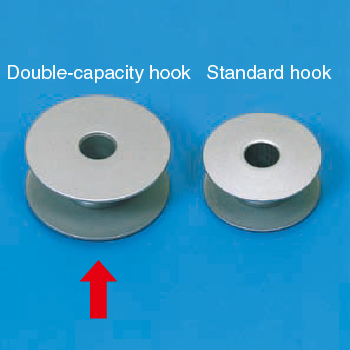

When you place orders