1-needle, Unison-feed, Lockstitch Machine with Double-capacity Hook

With its reliable feed and consistent seam quality, the machine responds outstandingly to the sewing of heavy materials.

With its larger needlebar stroke, higher presser foot lift, and newly adopted double-tension mechanism, the machine offers excellent sewing capabilities and responsiveness.

Product features

Excellent sewing capabilities and feed performance

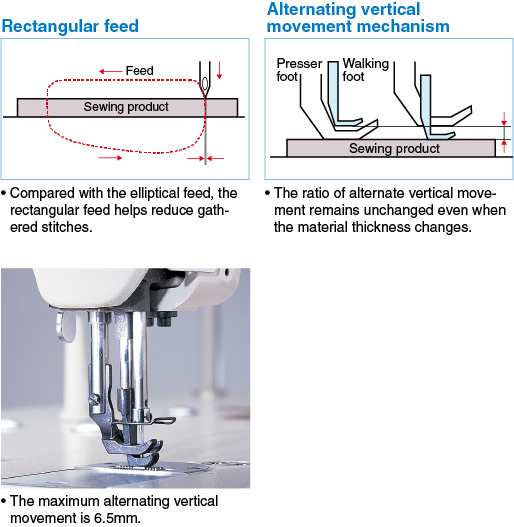

The alternating vertical movements of the walking foot and presser foot are as large as 6.5mm.

In addition, the ratio between alternating vertical movements of the walking foot and presser foot remains unchanged even when the material thickness changes. Thanks to this feature and the adoption of a new method of rectangular feed that prevents needle from fraying, the machine sews multi-layered parts of a material with consistent stitching pitch while preventing stitch gathering.

High-speed performance increases productivity

The machine delivers increased productivity at sewingspeeds as high as 2,500sti/min (DNU-1541, -1541S) or 3,000sti/min (DNU-1541-7).

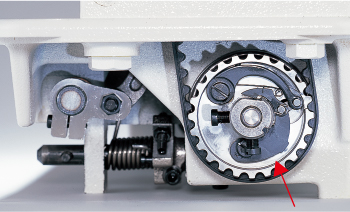

Safety mechanism (DNU-1541S)

When the thread is caught in the hook or any other sewing trouble occurs, the safety mechanism will automatically operate to prevent the machine from being damaged.

The vertical stroke of the walking foot and presser foot can be easily set and changed

The vertical stroke of the presser foot and walking foot (amount of alternating vertical movement) can be easily changed with the large dial mounted on the top of the machine head. The sewing speed is automatically regulated based on the vertical stroke setting. This ensures ideal sewing conditions at all times.

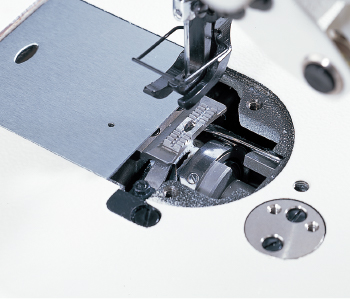

Thread trimming without fail (DNU-1541-7)

Consisting only of a moving knife and counter knife, the simple and well-balanced thread trimming mechanism is capable of cutting thick thread up to without fail.

A helpful automatic reverse feed function is provided as standard

With just a light press on the one-touch type reverse feed button, reverse feed stitching is actuated. Furthermore, if a suspended ruler is attached on the machine or a 3-dimensional sewing product is sewn, the button can be shifted upward to prevent interruption.

Basic performance

Excellent operability and maintainability

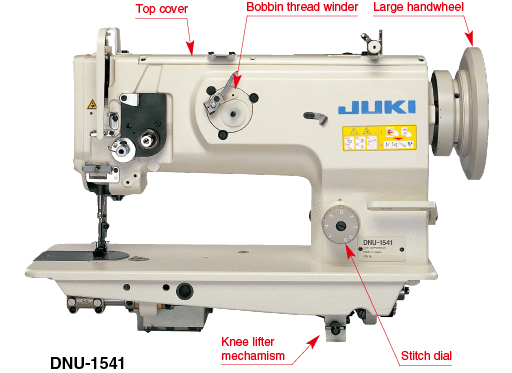

The stitch length can be easily selected by the stitch dial.

The machine's enhanced operability features include a clear view of the area around the needle, placement of the bobbin thread winder on the front face of the machine arm, and a large handwheel (φ160mm).

A knee-lifter mechanism is built in the bed. This reduces the pressure required to operate the knee-lifter and facilitates setup.

The machine’s full-open-type top cover design makes adjusting works easier.

The machine comes with a lubricating mechanism that uses a centralized oil wick. This substantially reduces the time and trouble required for oiling the machine. (Hook : automatic.)

A walking foot mechanism is built into the machine arm to prevent oil from scattering

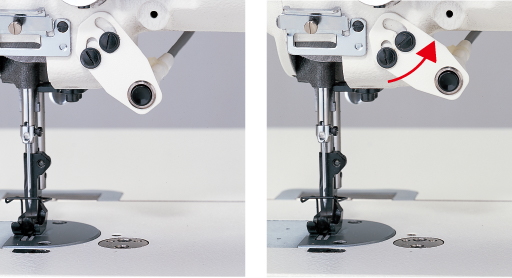

The area around the needle entry is designed to be easilyobserved

Since the needle thread tension-release solenoid is fitted on the rear face of the machine head, the area around the needle entry and one-touch type reverse feed button is easily viewable. This substantially contributes to improved operability.

Specification

| Model name | DNU-1541 | DNU-1541S | DNU-1541-7 |

|---|---|---|---|

| Max. sewing speed | 2,500sti/min* | 3,000sti/min* | |

| Max. stitch length | 9mm (forward / backward) | ||

| Needle bar stroke | 36mm | ||

| Lift of the presser foot | By hand: 9mm, By knee: 16mm | ||

| Thread take-up | Slide type | ||

| Amount of alternating vertical movement | 2.5~6.5mm | 1~6.5mm | |

| Dial for adjustment of alternating vertical movement |

- | Provided as standard | |

| Bottom-feed adjusting mechanism | - | Provided as standard | |

| Hook | Horizontal-axis full-rotary double-capacity hook | ||

| Needle (at the time of delivery) | 135×17 (Nm160) Nm125~Nm180 | ||

| Thread | #30~#5, B46~B138, Nm=60/3~15/3 | ||

| Pitch changing method | By dial | ||

| Bobbin thread winder | Provided as standard | ||

| Knee-lifter mechanism | Provided as standard | ||

| Safety mechanism | - | Provided as standard | - |

| Lubrication | Centralized oil wick lubrication (hook: automatic) | ||

| Lubricating oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) | ||

| Distance from needle to machine arm | 264mm | ||

| Bed size | 477mm×178mm | ||

| Automatic reverse feed function | Option | Provided as standard | |

| Compressed air and air consumption | - | 0.5MPa (5kgf/cm²), 0.3Nl/min | |

| Motor output | 750W | ||

| Power requirement | - | Single-phase 100~120V, 200~240V 3-phase 200~240V |

|

| Weight of the machine head | 36.5kg | 42.5kg | |

*"sti/min" stands for "Stitches per Minute."

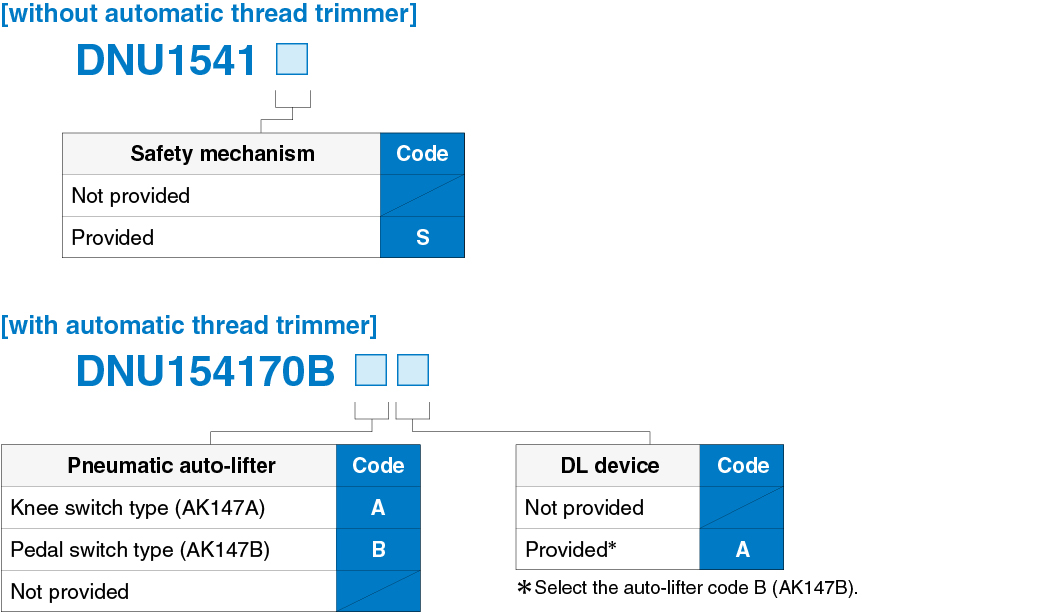

When you place orders