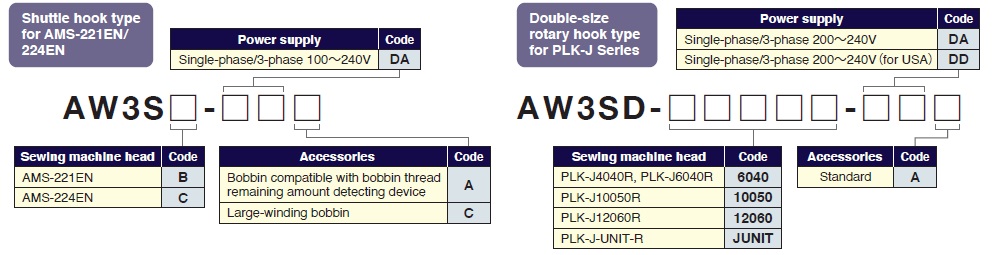

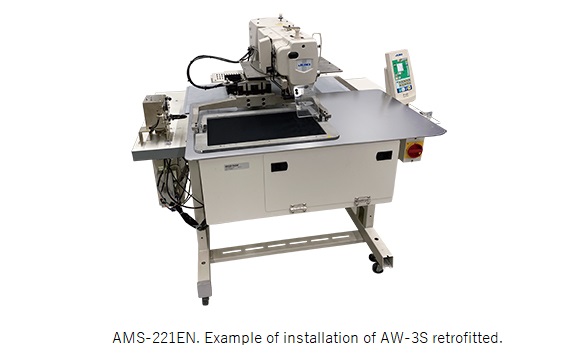

Automatic Bobbin Thread Wind-and-Feed Device

(Retrofit Kit for AMS-EN Series Shuttle Hook Type / PLK-J Series Double-size Rotary Hook Type)

Computer-controlled cycle machines with input functions can be fitted with a retrofitted automatic bobbin thread wind-and-feed device to achieve high sewing quality,

productivity, and ease of operation.

Product overview

Product features

Supported models

・AMS-221EN Series(Shuttle hook type)

・AMS-224EN Series(Shuttle hook type)

・PLK-J Series(Double-size rotary hook type)Increasing productivity !

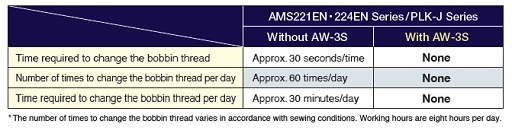

In case of AMS-22*EN /PLK-J Series without AW-3S, approximately 30 seconds are generally required every time the operator changes the bobbin thread manually. On the other hand, In case of AMS-22*EN /PLK-J Series installed with AW-3S, the bobbin thread is automatically changed while the operator picks up the sewn product and places a new material to be sewn on the sewing machine, thereby eliminating the downtime due to manual replacement of the bobbin thread. As a result, productivity is increased. Considering that bobbin thread replacement has always been an obstacle to automatization, AW-3S opens up further possibilities for automatization.

Basic performance

Consistent seam quality !

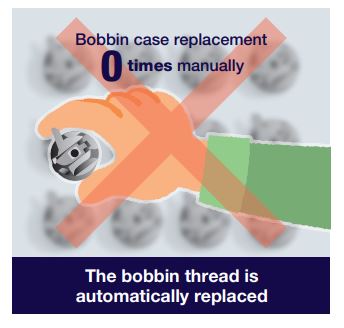

Bobbin thread replacement is carried out frequently. In general, the operator manually changes the bobbin.By retrofitting AW-3S to the sewing machine, not only the bobbin can be automatically changed before it runs out of thread, but also an empty bobbin can be wound with thread during sewing.

The operator is able to concentrate on sewing without worrying about the remaining amount of the bobbin thread.

In addition, the operator neither need to worry about the timing of changing the bobbin nor have to replace the bobbins by himself/herself.

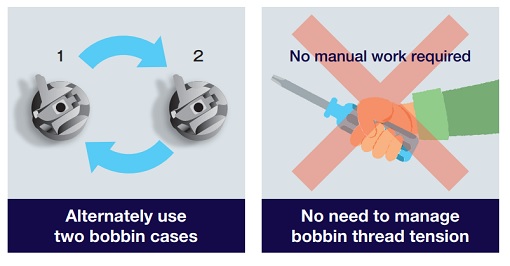

Moreover, only two bobbin cases are used alternately in repetition. It means that uniform bobbin thread tension and consistent seam quality are achieved without requiring

additional adjustment of the bobbin thread tension.Reduction of the bobbin thread consumption (Number of stitches memory mode: Automatic)

When loading a sewing pattern, AW-3S automatically calculates the bobbin thread amount to be consumed to sew the next sewing pattern and determines whether the sewing machine can complete the sewing of the pattern with the bobbin thread amount remaining before the start of sewing. If the remaining amount of the bobbin thread is not enough for sewing the loaded sewing pattern, AW-3S will automatically change the bobbin to another bobbin that is fully wound with thread. (AW-3S is able to automatically wind the preset amount of thread on a bobbin.) In addition, AW-3S gradually adjusts the length of thread remaining on the bobbin that has to be removed to an appropriate length.

High operability and workability

Since AW-3S automatically feeds the bobbin thread, it is no longer necessary for the operator to get under the machine to manually change the bobbin thread. This contributes to the reduction of the operator’s fatigue. With AW-3S, the operator is able to concentrate on sewing work without worrying about the remaining amount of the bobbin thread. In addition, AW-3S allows even a new operator who has just joined the company to carry out sewing work immediately.

Specification

| Device | AW-3S | ||

|---|---|---|---|

| Sewing machine head to which the device is installed | AMS-221EN / AMS-224EN | PLK-J Series | |

| Applicable bobbin and bobbin case | Bobbins and bobbin cases for shuttle hook | Bobbins and bobbin cases for double-size rotary hook | |

| Thread | #5~#30, 135~45(TEX), 020~060(TKT) | ||

| Applicable types of thread | Tetoron thread, nylon thread | ||

| Remaining thread removal operation, bobbin winding and threading operations |

Automatic(while the sewing machine is in operation) | ||

| Input device | IP-420(for AMS-221EN / AMS-224EN) | PAL(for PLK-J) | |

| Power requirement | Single-phase/3-phase 100~240V | Single-phase/3-phase 200~240V | |

| Power consumption | 100 VA | ||

| Compressed air | 0.5 Mpa | ||

| Max air consumption | 156dm3(ANR)/min | ||

When you place orders