Pinpoint Saddle Stitching Machine

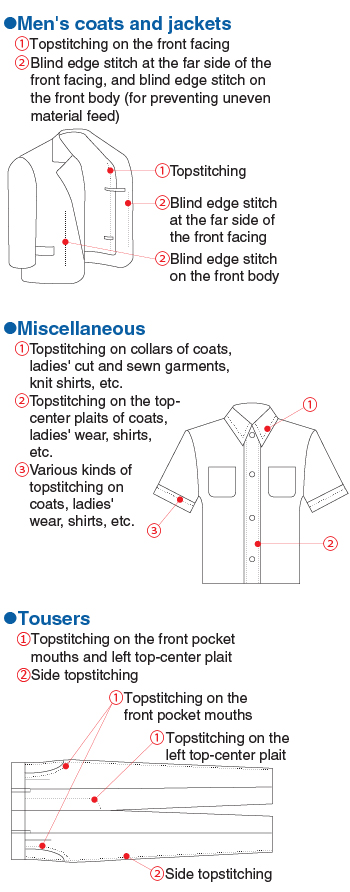

This pinpoint stitch machine is used for topstitching on the front facing of men's wear, as well as front flies, pocket mouths and trouser sides, as a cost-effective topstitching machine that offers increased productivity.

Product features

Excellent seam quality

In addition to balloon-stitching (to produce seams with a hand-stitched touch), smooth sewing of chain-off stitches, and having other outstanding seam quality features of the highly regarded Columbia 100, the MP-200N achieves more improved sewing capabilities and a wider adjustment range.

Responding to the sewing of various types of materials

The machine comes with a box type feed that permits a split adjustment in both horizontal and vertical directions, thereby responding to the sewing of various types of materials. Additionally, the inclination of the feed dog is also adjustable in accordance to the material.

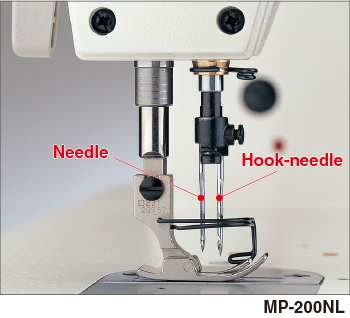

Positioning of needles with increased accuracy

Gauges that are determined by the combination of needles and spacers are of the Columbia type.

This improves the accuracy of the installation of needle positions, which determines the seam quality.

Wider range of applicable needle gauges and yarn counts

- Needle gauges support, using replacement parts, stitch widths from as narrow as 1.2mm to as wide as 5.0mm.

- The applicable range of yarn counts has been widened from #60 to #8 (B33, Nm = 120/3) for both Tetron and spun thread. This allows the machine to be used for topstitching a wider range of items.

Basic performance

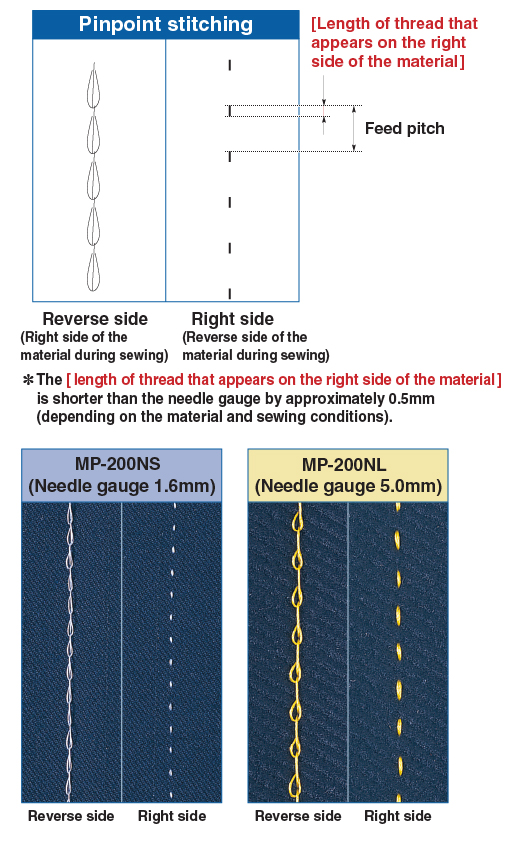

Uses of pinpoint stitching

It can be used for a wider range of applications requiring narrower to wider stitch widths.

Specification

| Model name | MP-200NS | MP-200NL | |||

|---|---|---|---|---|---|

| Max. sewing speed | 2,000sti/min* (feed pitch 6mm or less) 1,500sti/min* (feed pitch 6~8mm) 1,200sti/min* (feed pitch 8~10mm) |

1,500sti/min* (feed pitch 6~8mm) 1,200sti/min* (feed pitch 8~10mm) |

|||

| Pinpoint stitch width (needle gauge) |

1.6mm (2.0mm: Spacer is required to be changed with the one supplied with the machine) |

5.0mm | |||

| Length of thread that appears on the right side of sewing product (reference) | 1.1mm | 4.5mm | |||

| Feed pitch | 3.5~10mm | 10mm (For the needle gauge of 5mm) | |||

| Recommended feed pitch | 3.5~10mm (feed pitch that is larger than double of needle gauge is recommended) | ||||

| Applicable range of gauges | 1.2~2.5mm (for 1.2 and 2.5mm, optional parts are required) |

3.0~5.0mm (for 3 and 4mm, optional parts are required) |

|||

| Needle (at the time of delivery) |

Needle | SCHMETZ 29C150 (Nm90) Nm80~Nm140 | ORGAN CP×1J (#22U) #18U~#22U | ||

| Hook-needle | SCHMETZ 29C151 (Nm100) Nm80~Nm140 | ORGAN CP×12J (#23) #19~#30 | |||

| Recommended thread | Tetron • Spun | Tetron • Spun | |||

| Recommended yarn count | #60~#30, B33~B46, Nm=120/3~60/3 | #30~#8, B46~B92, Nm=60/3~30/3 | |||

| Recommended material/process | Wool, lining/ facing-topstitching process | Flannel/ topstitching peripheries of collars and pockets | |||

| Lift of the presser foot | By hand: 5.5mm/By knee: 10.5mm | ||||

| Split adjustment of feed (vertical/horizontal direction) |

Possible | ||||

| Lubrication | By an oiler | ||||

| Lubricating oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) | ||||

* “sti/min” stands for “Stiches per Minute”

When you place orders

Gauge

MP-200NS

MP-200NL

| Guage | GUAGE SET | GUAGE SET | THROAT PLATE | NEEDLE CLAMP | SPACER | PRESSER FOOT ASM. | ||

|---|---|---|---|---|---|---|---|---|

| Figure | - | - |  |

|

|

|

||

| Needle width | P/N | P/N | P/N | P/N | P/N | P/N | ||

| mm | ||||||||

| 1.2 | 23124357 | 23124366 | 23123003 | 23124100 | 23124308 | 23122658 | ||

| 1.6 | - | 23124456 | 23123102 | 23124100 | 23124407 | 23122658 | ||

| 2.0 | - | 23124555 | 23123102 | 23124100 | 23124506 | 23122658 | ||

| 2.5 | 23124654 | 23124663 | 23123201 | 23124100 | 23124605 | 23122658 | ||

| 3.0 | 23124852 | 23124861 | 23123300 | 23124803 | - | 23122757 | ||

| 4.0 | 23124951 | 23124960 | 23123409 | 23124902 | - | 23122757 | ||

| 5.0 | 23125057 | - | 23123508 | 23125008 | - | 23122757 | ||

| Remarks | S Type | L Type | - | - | - | - | ||

| Guage | NEEDLE HOLDER | NEEDLE CLAMP HOOK | SPREADER MOUNTING TABLES (PAIRS) | SPREADER | LOOPER CRANK | ||

|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

||

| Needle width | P/N | P/N | P/N | P/N | P/N | ||

| mm | |||||||

| 1.2 | 23124209 | - | 23125750 | 23138209 | 23136104 | ||

| 1.6 | 23124209 | - | 23125750 | 23138209 | 23136104 | ||

| 2.0 | 23124209 | - | 23125750 | 23138209 | 23136104 | ||

| 2.5 | 23124209 | - | 23125750 | 23138209 | 23136104 | ||

| 3.0 | 23125107 | 23125404 | - | 23125800 | 23121502 | ||

| 4.0 | 23125206 | 23125404 | - | 23125909 | 23121502 | ||

| 5.0 | 23125305 | 23125404 | - | 23126006 | 23121502 | ||

| Guage | NEEDLE BAR CRANK | SYNCHRONIZER BOSS | SYNCHRONIZER MOUNTING POLE | SYNCHRONIZER MOUNTING POLE NUT | |||

|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|||

| Needle width | P/N | Thread take-up timing | P/N | P/N | P/N | ||

| mm | |||||||

| - | 23121205 | Standard±10° | 22622401 | 23141906 | NM6040001SC | ||

| - | 23121304 | Standard±10° | |||||

| - | 23121403 | Free configuration | |||||