Variable Top-feed, Overlock / Safety Stitch Machine for Extra Heavy-weight Materials

An advanced full-featured machine that is ideally suited to the sewing of extra heavy-weight materials.

The machine incorporates a mechanism and parts that are optimum for the sewing of extra heavy-weight materials, such as an extra high-lift type upper looper, tractor foot and coarse type feed dog.

It demonstrates an excellent performance ability in the sewing of various kinds of heavy-weight materials such as jeans, raised fabric materials, mats and carpets.

PEGASUS : EXT series

Product features

An advanced full-featured machine that is ideally suited to the sewing of extra heavy-weight materials

The MO-6900J Series comes with a newly-developed feed mechanism that moves the top and bottom feeds separately.

With its improved feeding capacity and stronger cloth-biting force, the feed mechanism prevents uneven material feed when sewing extra heavy-weight materials.

- The machine incorporates mechanisms that are both durable and reliable, such as the needle bar mechanism, utilyzing the upper and lower bushings, a cartridge type oil filter and cooling fan.

- The machine is equipped as standard with a micro-lifter that helps reduce operator fatigue. The micro-lifter is designed to achieve optimum balance, not only reducing noise and vibration but also ensuring comfortable operation.

- Needle thread heat remover and needle cooler prevent stitching troubles during times of high-speed sewing, thereby contributing to upgraded seam quality.

- The machine comes standard with various adjusting mechanisms, such as a micro-adjusting mechanism, all of which can be easily adjusted to enable the machine to perform sewing under the best-suited conditions for any kind of material.

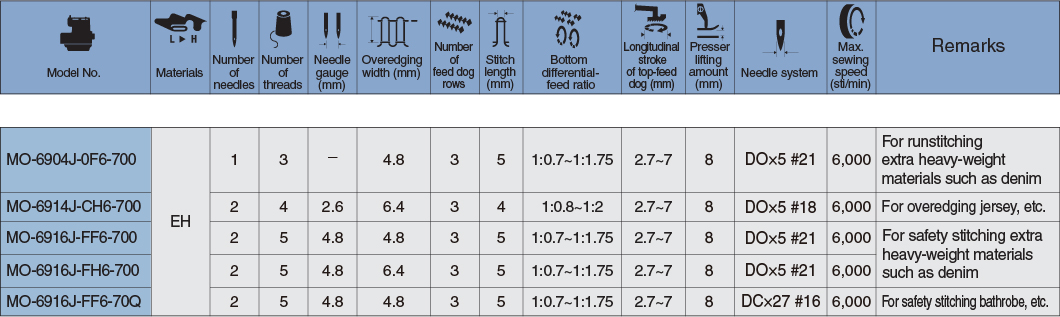

Specification

| Model name | MO-6904J | MO-6914J | MO-6916J | |

|---|---|---|---|---|

| Stitch type | 1-needle overlock | 2-needle overlock | Safety stitching | |

| Stitch style in the U.S.A. | 504 | 514 | 516 | |

| Max. sewing speed | 6,000sti/min* | |||

| Stitch length | 2.5~5mm | 2.5~4mm | 2.5~5mm | |

| Needle gauge (mm) | - | 2.6 | 4.8 | |

| Overedging width (mm) | 4.8 | 6.4 | 4.8, 6.4 | |

| Bottom differential feed ratio | For gathering 1:1.75 (max. 1:3.8) For stretching 1:0.7 (max. 1:0.6) |

For gathering 1:2 (max. 1:3.8) For stretching 1:0.8 (max. 1:0.6) |

For gathering 1:1.75 (max. 1:3.8) For stretching 1:0.7 (max. 1:0.6) |

|

| Needle bar stroke | 28.8mm | |||

| Inclination angle of the needle | 20° | |||

| Needle bar bushing | Upper/lower bushing method | |||

| Needle | DO×5 (excluding some subclass model) | |||

| Vertical stroke of top feed dog | 8.5mm | |||

| Longitudinal stroke of top feed dog | 2.7~7mm (it differs with the machine's specifications.) | |||

| Max. lift of the presser foot | 8mm (excluding some subclass model) | |||

| Max. presser foot pressure | 63.7N (6.5kgf) | |||

| Stitch adjusting method | By push-button | |||

| Bottom differential feed adjusting method | By lever (with micro-adjustment) | |||

| Top differential feed adjusting method | By lever (with micro-adjustment) | |||

| Weight of the machine head | 29kg | |||

| Lubrication | Automatic | |||

| Lubricating oil | JUKI Machine Oil 18 (equivalent to ISO VG18) | |||

| Needle cooler | Provided as standard | |||

| Needle thread heat remover | Provided as standard | |||

| Micro-lifter | Provided as standard | |||

* "sti/min" stands for "Stitches per Minute"

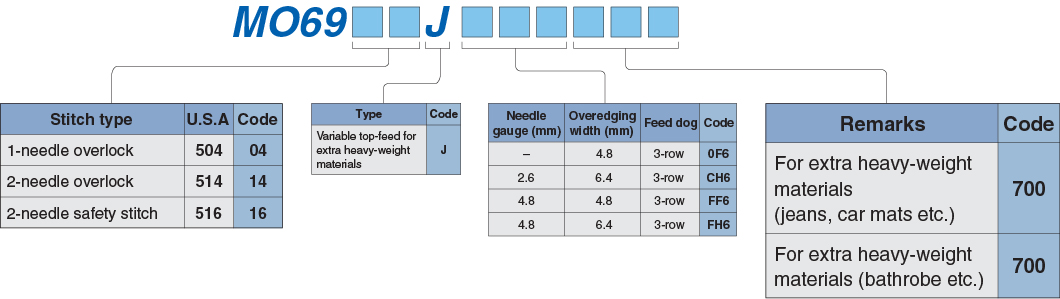

When you place orders

Subclass machine list

Gauge

MO-6904J-0F6-700

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | UPPER FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8 | R4300J6FL00 | 11701604 | 11651809 | 11700507 | 12388807 | 12022950 | 11925104 | 12022901 | 13255005 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8 | 12384202 | 12382402 | 13104104 | B411180400E | 11566502 | 12015509 | 11890001 | 11545100 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Overedging width | P/N | P/N |

| 4.8 | 13221304 | 40026021 |

MO-6914J-CH6-700

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | UPPER FEED DOG | PRESSER FOOT ASM. | PRESSER FOOT HINGE | PRESSER FOOT | NEEDLE CLAMP |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2.6*6.4 | R4306J6HJ00 | 12013306 | 11651809 | 12013405 | 12388906 | 12012555 | 11925104 | 12012506 | 13255104 |

| Guage | UPPER LOOPER | LOWER LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE |

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 2.6*6.4 | 12383600 | 12384202 | 31200900 | B411180400E | 11566502 | 12015509 | 11890001 | 11545100 |

| Guage | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|

| Figure |  |

|

| Overedging width | P/N | P/N |

| 2.6*6.4 | 13221304 | 40026021 |

MO-6916J-FF6-700

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | UPPER FEED DOG | HINGING PRESSER ASM. | PRESSER FOOT HINGE | FRONT PRESSER | REAR PRESSER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | R4612J6FL00 | 12382503 | 11528502 | 11528403 | 12389003 | 12023255 | 12024402 | 12023206 | 12023305 |

| Guage | CHAIN LOOPER NEEDLE CLAMP | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE |

|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 13255203 | 12383501 | 12384202 | 12384400 | 13105507 | 11565900 | 11566502 |

| Guage | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 12384509 | 12015400 | 12015301 | 11890001 | 11545100 | 13221304 | 40026021 |

MO-6916J-FH6-700

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | UPPER FEED DOG | HINGING PRESSER ASM. | PRESSER FOOT HINGE | FRONT PRESSER | REAR PRESSER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*6.4 | R4612J6HL00 | 12382503 | 11528502 | 11528403 | 12389003 | 12023255 | 12024402 | 12023206 | 12023305 |

| Guage | CHAIN LOOPER NEEDLE CLAMP | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE |

|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*6.4 | 13255203 | 12383501 | 12384202 | 12384400 | 13105507 | 11565900 | 11566502 |

| Guage | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*6.4 | 12384509 | 12015400 | 12015301 | 11890001 | 11545100 | 13221304 | 40026021 |

MO-6916J-FF6-70Q

| Guage | THROAT PLATE | MAIN FEED DOG | AUXILIARY FEED DOG | DIFFERENTIAL FEED DOG | UPPER FEED DOG | HINGING PRESSER ASM. | PRESSER FOOT HINGE | FRONT PRESSER | REAR PRESSER |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | R4612J6FG0A | 12382503 | 40014688 | 11528403 | 12389003 | 12023255 | 12024402 | 12023206 | 12023305 |

| Guage | CHAIN LOOPER NEEDLE CLAMP | UPPER LOOPER | LOWER LOOPER | CHAIN LOOPER | CHIP GUARD COVER | UPPER KNIFE | LOWER KNIFE |

|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 40012200 | 11993656 | 12384202 | 12384400 | 13105507 | 11565900 | 11566502 |

| Guage | NEEDLE HOLDER | NEEDLE HOLDER | NEEDLE HOLDER | TRAVELING NEEDLE GUARD | GUIDE SUPPORT GAUGE | UPPER LOOPER ARM | UPPER LOOPER GUIDE |

|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

| Overedging width | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 4.8*4.8 | 12384509 | 40014687 | 12015301 | 11890001 | 11545100 | 13221304 | 40026021 |