Automatic 2-needle Belt-Loop Attaching Machine

The MOL-254N feeds, cuts, and sews belt loops automatically at high speeds with high-quality output.

Product features

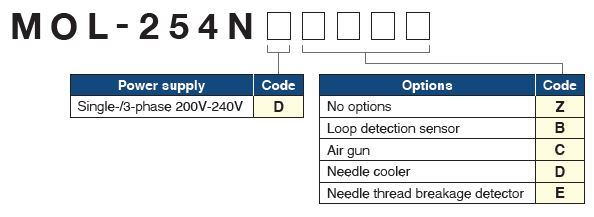

The folding fork and gate-shaped presser ensure the sewing of quality belt loops with no dog ears

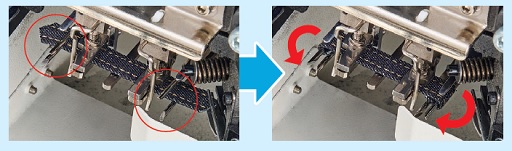

The folding fork pinches the fabric according to the thickness of the belt loop, eliminating fabric misalignment within the fork and ensuring secure loop bending. The newly adopted gate-shaped presser securely fastens and sews belt loops and helps to prevent dog ears and stitch skipping.

Folding fork

Gate-shaped presser

The gate-shaped presser surrounds belt loops to be sewn from all sides to stop the fabric from shifting during sewing.

New fullness mechanism provided as standard equipment

The new fullness mechanism provided as standard firmly holds the belt loop and loosens it (fullness) in a swift and stable motion according to the selected quality specifications.

Basic performance

With its machine head exclusively developed for sewing belt loops and its belt loop supply unit

Equipped with a direct drive system. High work efficiency is achieved with the improved start-up performance and sewing speed. The belt loop supply device has a halfway standby function for the next batch of belt loops. Automatic resupply after supply failure reduces downtime.

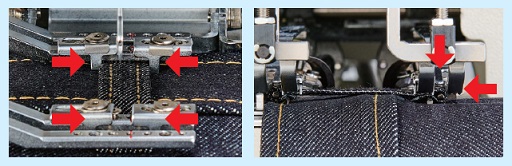

The computer-controlled X-Y linear feed system lets you program the number of stitches and bartacking size

Change the bartacking size and stitch number for belt loop sewing with a few easy taps on the operation panel.

You can switch between cross cut and straight cut, as well as switch the cut length. Since the cut length is shortened, cutting work in the next process can be omitted.

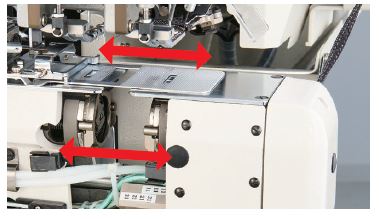

The motorized back-and-forth movement of the hook shaft during needle-width adjustment eliminates the need for feed plate replacement

Move the hook shaft back and forth by motor when changing the needle width. Simply loosen a screw to adjust the feed plate. These simple features spare you the effort and cost of parts replacement.

Specification

| Model name | MOL-254N |

|---|---|

| Machine head | Computer-controlled, 2-needle, lockstitch bartacking machine |

| Max. sewing speed | 2,500sti/min* |

| Thread take up | Spun thread, cotton thread #50~#30, B33~B46, Nm=120/3~60/3 |

| Needle (at the time of delivery) | DP×17 (#21) #19~#21 |

| Hook | Horizontal-axis 1.8 fold-capacity shuttle hook |

| Lift of the presser foot | 21mm |

| Number of stitches | 28, 36, 42 (selectable on the operating panel) |

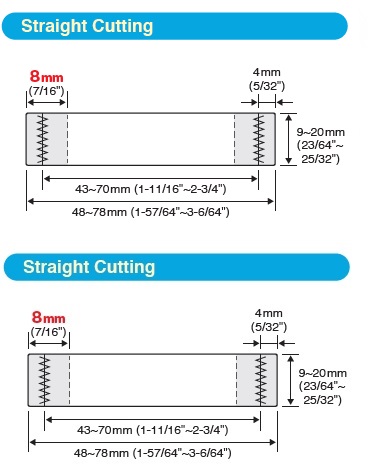

| Needle gauge | 43~70mm (1-11/16"~2-3/4") |

| Bartacking length | 7~22mm (9/32"~55/64") ‹adjustable in increments of 0.1mm› |

| Bartacking width | 1~3.2mm (3/64"~1/8") ‹adjustable in increments of 0.1mm› |

| Number of pieces of bartacking data that can be stored in memory | 9 (99 patterns if optional EP-ROM is added) |

| Belt-loop width | 9~20mm (23/64"~25/32") |

| Finished length of belt-loop | 48~78mm (1-57/64"~3-5/64") |

| Machine time | 1.2 sec./belt-loop (28 stitch) |

| Positioning of the front hook | Driven by motor (the distance between the hook can be established in increments of 0.01mm) |

| Bobbin winder | Electric type (provided as standard) |

| Lubrication | Centralized oil wick lubrication (machine head) |

| Lubricating oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) |

| Power requirement and power consumption | Single-phase, 3-phase 200~240V/350VA |

| Compressed air and air consumption | 0.5MPa (5kgf/cm²), 32Nl/min |

| Total weight | 230kg |

| Dimensions | 1,200mm (W)×800mm (D)×1,350mm (H: in its lowest end) |

| Height of the top surface of the throat plate as from the floor surface | 920~1,250mm (provided with the adjustable stand capability) |

*"sti/min" stands for "Stitches per Minute."