Edge Control Seamer

This is an edge control seamer which automatically produces beautiful "seams" on materials in diversified designs.

With JUKI's unique material end control technique, the sewing machine joins materials with delicate and high-quality seams.

Product features

High-quality joining of materials

The sewing machine is applicable to the sewing of materials with different curves and different-in-kind materials.

It is necessary for the joining of materials with beautiful textures added to carry out sewing of the materials and aligning their ends with notches simultaneously.

The AE-200A allows, through by its unique techniques, inexperienced operators to perform this difficult and skill-requiring process simply by placing the materials on the sewing machine. The sewing machine enables control of shirring and stretching of materials on a section-by-section basis by dividing the sewing length into ten different sections at the maximum. As a result, high-quality and consistent joining of materials is enabled even if the materials have complicated curves.

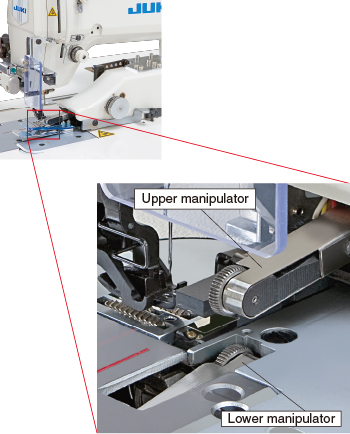

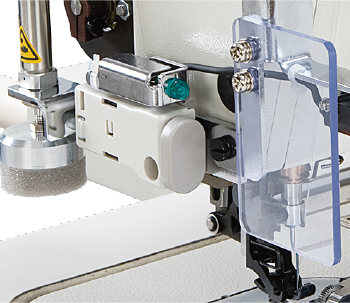

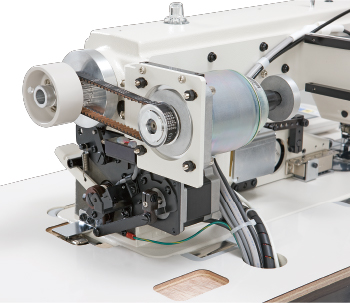

The manipulator is a JUKI unique device which enables accurate joining of materials by active pressure and rotation of the rollers.

* "Active pressure" (AP) is a JUKI unique new function that controls the pressures of the upper and lower manipulators separately according to the material and sewing specifications. (The manipulator pressures can be controlled in 10 different sections in one pattern.)

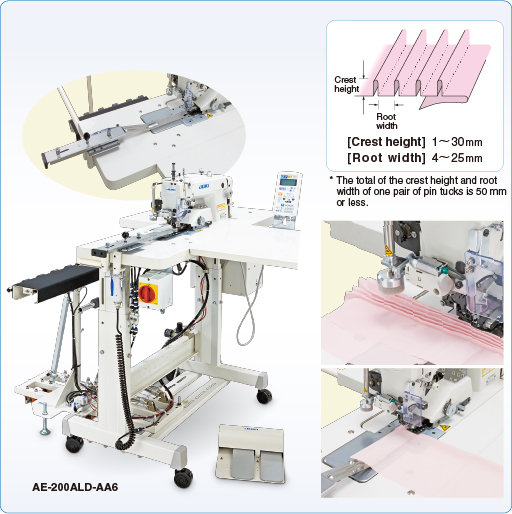

AE-200ALD Pin tuck type

The sewing machine is able to produce beautiful and equally-spaced pin tucks by installing the pin tuck device (40088621).

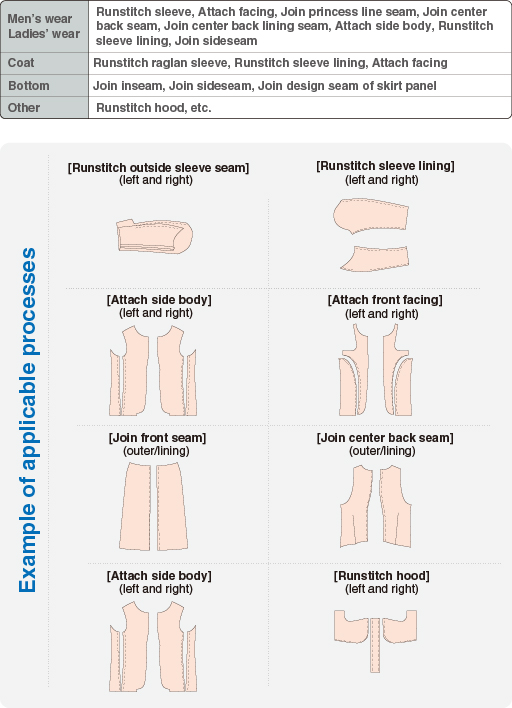

Applications

The sewing machine is applicable to many different processes such as sewing the center of the back and joining the sides of garment bodies of men's and ladies jackets and ladies skirts.

Simple operation of the operation panel

Sewing data can be input and programmed with ease on the operation panelThe number of pieces of sewing data that can be stored in its memory is 99 at the maximum.

Setting and selection of all sewing data can be done on the operation panel. Data items are displayed in easy-to-understand pictographs on the LCD. As many as 99 different patterns of sewing data can be stored in its memory. One sewing pattern can be divided into 10 sections. For the respective sections, the number of stitches, top and bottom differential feed, and upper and lower manipulator pressures can be numerically input.Cycle sewing

The sewing machine is able to continuously carry out different processes such as joining the sides of right and left garment bodies and sewing the center of the back by means of the cycle function.

*As many as 15 patterns can be carried out in one cycle and as many as 20 cycles can be stored in its memory.

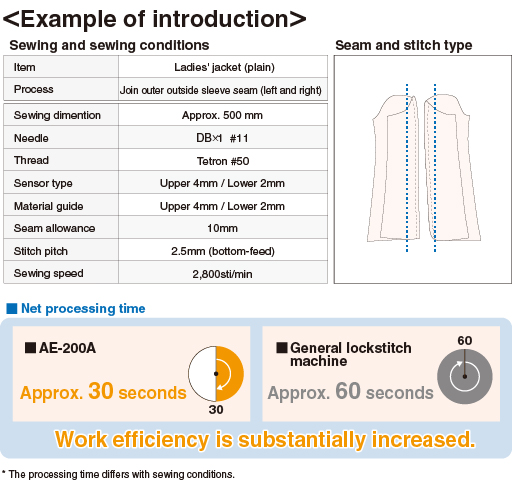

Productivity is substantially increased

The operator is only required to place materials on the sewing machine. The sewing machine automatically and continuously sews the materials while aligning the materials' ends until the sewing end is reached.

When comparing the length of time required to sew front-cloth sleeve arm top of ladies jackets by using the AE-200A with that by using a general lockstitch machine, the former requires only half the time required by the latter.

Basic performance

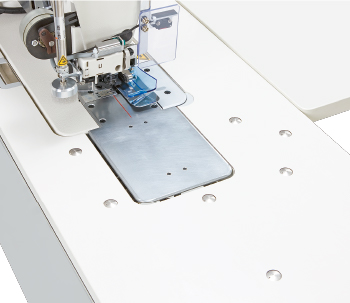

Air-blow table

The sewing machine is provided as standard with an air blower which helps feed the material, thereby improving workability.

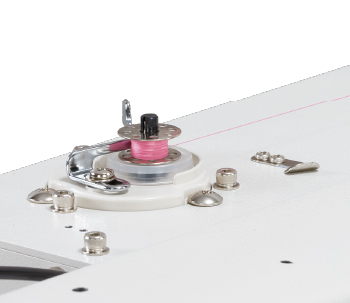

Bobbin winder

In order to improve the workability at bobbin thread changing, the bobbin winder is placed on the top of the main motor cover.

Handy switch

The start/pause switch is provided close at hand as standard. The switch is located near the position where the operator places the materials on the sewing machine, allowing the operator to carry out sewing in a responsive manner.

TBD system*

A timing belt drive system has been adopted for the AE-200A. This system allows the sewing machine to start sewing with no loss of the driving force.

*TBD stands for Timing Belt Drive.

Specification

| Model name | AE-200ALA | AE-200ALD |

|---|---|---|

| Application | Join materials type (medium-weight) | Pin tuck type |

| Machine head | DLU-5498N-7 (exclusive machine head for AE-200A) | |

| Sewing speed | 200~3,500sti/min* | |

| Max. stitch length | 4mm | |

| Max. top-feed amount | 8mm | |

| Lift of the presser foot | 10mm | |

| Needle | DB×1 (#11) #9~#18 | |

| Sewing condition | (Seam allowance) 1~30mm (Curve sewing) 100mmR or more (Number of plies) Two or one |

|

| Compressed air | 0.5MPa | |

| Power requirement Power consumption |

Single, 3-phase 200~240V/220W | |

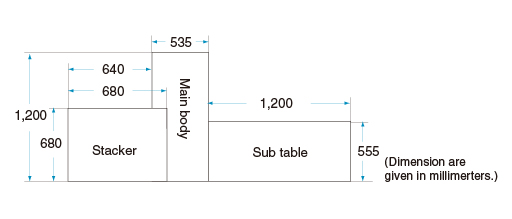

| Dimensions |  |

|

| Total weight | 135kg (when all options are installed) | |

*"sti/min" stands for "Stitches per Minute."

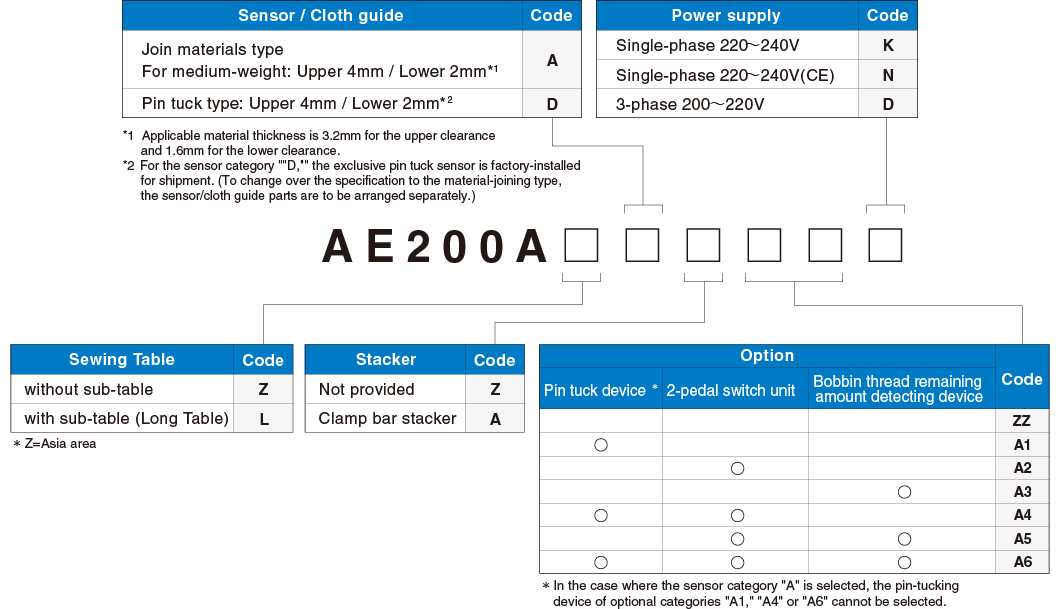

When you place orders