1-needle, Needle-feed, Lockstitch Machine

With its needle feed mechanism, the machine supports the operator, promotes efficiency in production, and upgrades the quality of finished products.

Product features

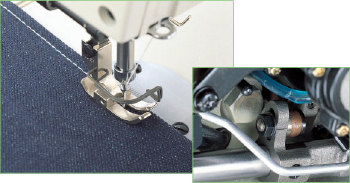

Sewing mechanism that demonstrates outstanding responsiveness to materials to be sewn

The machine head has been redesigned to improve the performance of each component. Thanks to the machine's low-tension sewing capability and the adjustment function for the needle feed amount (±15%), uneven material feeding and puckering rarely occur, thus enhancing the machine's ability to respond to any change in the material to be sewn.

The optimally balanced design of the machine head and the stronger frame structure significantly reduce machine vibration and noise while the machine is being operated.

Sure thread trimming mechanism

DLN-5410N-7 (with automatic thread trimmer)The moving knife has been designed so that it can be easily replaced, thus facilitating machine maintenance.

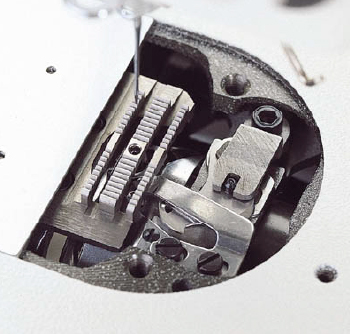

Durability and reliability of the machine are improved

It is designed to reinforce the feed components, lubrication components, and frame, and to seal hermetically the needle bar frame. As a result, durability and reliability of the machine are improved and economical efficiency will be remarkably enhanced.

The new model control box, which energy-saving mode is provided (SC-920C/M92)

The new model control box SC-920C has been newly developed. The control box is resistant to voltage fluctuations, noise and vibration.

The new model control box is provided with an energy-saving mode for the first time in a control box for sewing machines.

It reduces power consumption during standby time when the motor is not rotating by approximately 25 % (in comparison with the SC-910N).

In addition, the current DLN-5410N-7 is lavished with the latest energy-saving technologies, including the adoption of the latest compact servomotor M92, to be more friendly to theenvironment, as well as to provide the power reducing effect and to increase productivity.

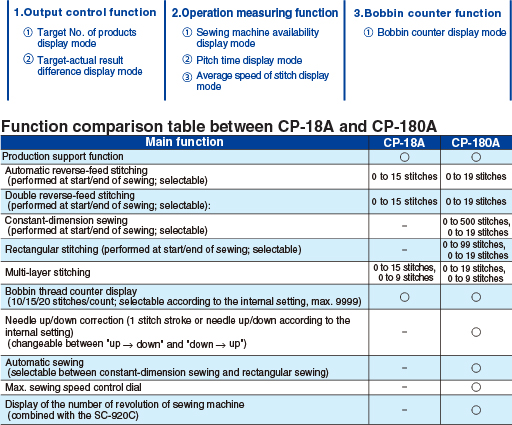

The operation panel can be selected according to the process (CP-18A, CP-180A)

Two different operation panels, the CP-18A and CP-180A are applicable to the DLN- 5410N-7. Both operation panels are provided with the production support function.

The production support function actually consists of three different functions (six different modes)

Basic performance

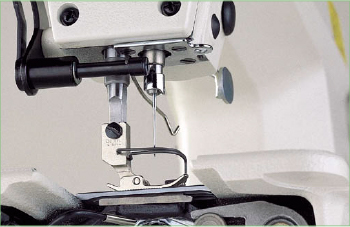

Higher lift of the presser foot

This machine is equipped with various devices that reduce the operator's fatigue and allow the operator to easily operate the machine. These devices include the following: The foot pedal needs only light pressure to be operated. The presser foot can be lifted as high as 13mm.

The shape of the machine arm has been designed to allow the operator to handle any material with ease.

Specification

| Model name | DLN-5410N | DLN-5410NH | DLN-5410NL |

|---|---|---|---|

| Application | For light- to medium-weight materials | For heavy-weight materials | For heavy-weight materials (long stitch length type) |

| Max. sewing speed | 5,000sti/min* | 4,000sti/min* | 3,000sti/min* |

| Max. stitch length | 4mm | 4.5mm | 6mm |

| Needle bar stroke | 30.7m | ||

| Lift of the presser foot | By hand: 5.5mm, By knee: 13mm | ||

| Needle (at the time of delivery) | DB×1 (#14) For JE: 134 (Nm90) | DB×1 (#21) For JE: 134 (Nm130) | DB×1 (#21) For JE: 134 (Nm130) |

| Hook | Automatic-lubricating full-rotary hook | ||

| Lubrication | Automatic | ||

| Lubricating oil | JUKI New Defrix Oil No.1 (equivalent to ISO VG7) | ||

| Model name | DLN-5410N-7 | DLN-5410NH-7 | DLN-5410NJ-7 |

|---|---|---|---|

| Application | For light- to medium-weight materials | For heavy-weight materials | For jeans |

| Max. sewing speed | 5,000sti/min* | 4,000sti/min* | |

| Max. stitch length | 4mm | 4.5mm | |

| Needle bar stroke | 30.7mm | 33mm | |

| Lift of the presser foot | By hand: 5.5mm, By knee: 13mm | ||

| Needle (at the time of delivery) | DB×1 (#14) For JE: 134 (Nm90) | DB×1 (#21) For JE: 134 (Nm130) | DB×1 (#21) For JE: 134 (Nm130) |

| Hook | Automatic-lubricating full-rotary hook | Automatic-lubricating double-capacity full-rotary hook | |

| Thread | - | #30~#8, B46~B92, Nm60/3~30/3 | |

| Lubrication | Automatic | ||

| Lubricating oil | JUKI New Defrix Oil No.1 (equivalent to ISO VG7) | ||

| Automatic reverse feed function | Provided as standard | ||

| Power requirement | Single-phase 100~120V, 200~240V, 3-phase 200~240V | ||

| Power consumption | 650VA | ||

| Total weight | 83kg | ||

*“sti/min”stands for“Stitches per Minute”

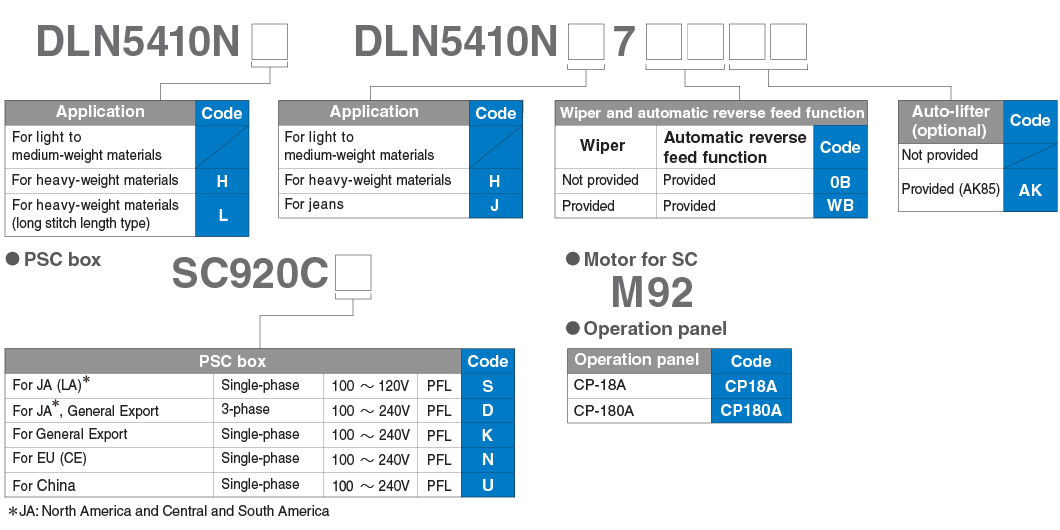

When you place orders

Gauge

DLN-5410N

| Guage | FEED DOG | THROAT PLATE | PRESSER FOOT | Features in sewing | |||||

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

||||||

| Application | P/N | Needle hole |

Pitch | Remarks | P/N | No. of grooves |

Thickness | P/N | |

| Standard For light to midium weight matelials |

D1609415B00 | 1.9 | 1.15 | 11300308 | 3 | 3.2 | D1524415BAA | Suited to the sewing of the material which is likely to cause slip-off of needle thread and stitch skipping. Pressure of the presser foot: Standard value. Needle: Standarad (#12~#18) Throat plate (11300308) provides higher durability than throat plate (B1109041F0B). |

|

| For light to midium weight matelials | B1609041B00 | 1.9 | 1.15 | B1109041B00 | 2 | 3.2 | B1524041A00 (B1524041EA0) (B15244120A0) (D1524415BAA) |

Suited to the sewing of curves and sharp curves. Widely used for overedging. Pressure of the presser foot: Standard value. Needle: Standarad (#12~#18) |

|

| For midium weight matelials | B1609041C00 | 1.9 | 1.25 | Provided with a thread path groove. | B1109041C00 | 1 | 3.2 | B15244120A0 (D1524415BAA) |

Suited to the sewing of sharp curves. Suited to the sewing which requires to be carried out using a binder in combmation wlth the gauge set. Widely used for overedging. Pressure of the presser foot: Standard value, or a slightly lower value. Needle: Standarad (#12~#18) |

| For light to midium weight matelials | B1609041D00 | 1.9 | 1.15 | Provided with a thread path groove. | B1109041D00 | 1 | 3.2 | B15244120A0 (D1524415BAA) |

When compared with B1609041C00, straight-feeding capability is improved. Suited to the sewlng of comparatlvely resilient materials. Widely used for overedging. Pressure of the presser foot: Standard value, or a slightly lower value. Needle: Standarad (#12~#18) |

| For light to midium weight matelials | B1609041F00 | 1.9 | 1.15 | Provided with a thread path groove. | B1109041F00 | 3 | 3.2 | B15244120A0 (D1524415BAA) |

Pressure of the presser foot: Standard value Needle: Standarad (#12~#18) |

| For light weight matelials | B1609415B00 | 1.6 | 1.15 | B1109415B00 | 3 | 2.6 | B15244120A0 (D1524415BAA) |

Suited to the sewing of the materiai that needs to be fed forward at the start of sewing. Suited to the sewing process where the overlapped section of the material shouid be sewn at the end of sewing or the material which is iikely to cause stitch skipping. Stitch length should not exceed 2.5 mm. Pressure of the presser foot: Slightly lower value. Needle: Thin (#8~#11) |

|

| For extra light weight materials (JE) | B1609415C00 | 1.3 | 1.15 | B1109415B00 | 3 | 2.6 | B15244120A0 (D1524415BAA) |

Suited to the sewing of the materiai that needs to be fed forward at the start of sewing. Suited to the sewing process where the overlapped section of the material shouid be sewn at the end of sewing or the material which is iikely to cause stitch skipping. Stitch length should not exceed 2.5 mm. Pressure of the presser foot: Slightly lower value. Needle: Thin (#7~#10) |

|

| For light weight materials for attaching collar bands | B1609415E00 | 1.6*2 | 1.15/1.2 | B1109415E00 | 2 | 2 | B15244120A0 | Stitch length should not exceed 2.5 mm. Needle: Thin (#8~#11) |

|

DLN-5410NH

| Guage | FEED DOG | THROAT PLATE | PRESSER FOOT | Features in sewing | |||||

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

||||||

| Application | P/N | Needle hole |

Pitch | Remarks | P/N | No. of grooves |

Thickness | P/N | |

| Standard For heavy weight materials | 11322203 | 2.4 | 1.7 | Provided with a thread path groove. | B1109415H0B | 3 | 3.2 | B1524041EA0 | Pressure of the presser foot: Slightly increase. Needle: Thick (#19~#23) |

| For medium weight materials (for JE) | B1609415D00 | 2*3.5 | 1.7 | Provided with a thread path groove. | B1109041A00 | 2 | 3.2 | B1524041AA0 | Suited to the sewmg of sharp curves. Widely used for overedging. Pressure of the presser foot: Slightly increase. Needle: (#14~#18) |

| For medium weight materials (for Hong Kong) | B1609415G00 | 1.9 | 1.7 | Provided with a thread path groove. | B1109415G00 | 5 | 3.2 | B15244120A0 | Efficlency of feed is increased. Needle: (#14~#18) |

| For heavy weight materials | B1509415H00 | 2.4 | 1.7 | Provided with a thread path groove. | B1109415H0B | 3 | 3.2 | B1524041EA0 | Pressure of the presser foot: Slightly increase. Needle: Thick (#19~#23) |

| For extra heavy weight materials | B1609415H0A | 2.4 | 2 | Provided with a thread path groove. | B1109415H0B | 3 | 3.2 | B1524041EA0 | Pressure of the presser foot: Slightly increase. Needle: Thick (#19~#23) |

| For medium weight materials | B1609041A00 | 1.9 | 1.7 | Provided with a thread path groove. | B1109041A00 | 2 | 3.2 | B1524041AA0 | Suited to the sewmg of sharp curves. Widely used for overedging. Pressure of the presser foot: Slightly increase. Needle: (#14~#18) |

| For medium weight materials | B1609041E00 | 1.9 | 1.7 | Provided with a thread path groove. | B1109041E00 | 3 | 3.2 | B1524041EA0 | Pressure of the presser foot: Slightly increase. Needle: Standard (#12~#18) |

DLN-5410NL

| Guage | FEED DOG | THROAT PLATE | PRESSER FOOT | Features in sewing | |||||

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

||||||

| Application | P/N | Needle hole |

Pitch | Remarks | P/N | No. of grooves |

Thickness | P/N | |

| Standard For heavy weight materials |

11322203 | 2.4 | 1.7 | Provided with a thread path groove. | B1109415H0B | 3 | 3.2 | B1524415LA0 | Pressure of the presser foot: Slightly increase. Needle: Standard (#19~#23) Stitch length: should not exceed 6mm. |

| For extra heavy weight materials | B1609415L00 | 2.4*3.4 | 1.7 | Provided with a thread path groove. | B1109415H0B | 3 | 3.2 | B1524415LA0 | Pressure of the presser foot: Slightly increase. Needle: Standard (#19~#23) Stitch length: should not exceed 6mm. |

DLN-5410N-7

| Guage | FEED DOG | THROAT PLATE | PRESSER FOOT | Features in sewing | |||||

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

||||||

| Application | P/N | Needle hole |

Pitch | Remarks | P/N | No. of grooves |

Thickness | P/N | |

| Standard For light to medium weight materials |

D1609415B00 | 1.9 | 1.15 | 11300308 | 3 | 3.2 | D1524415BAA | Suited to the sewing of the material which is likely to cause slip-off of needle thread and stitch skipping. Pressure of the presser foot: Standard value. Needle: Standarad (#12~#18) Throat plate (11300308) provides higher durability than throat plate (B1109041 FOB). |

|

| For light weight materials, ASAHI type | B1609415A00 | 1.6 | 1.15 | Provided with a thread path groove. | B1109415B0A | 3 | 2.6 | B15244120A0 | Needle: Thin (#8~#11) |

| For light to medium weight materials | B1609041F00 | 1.9 | 1.15 | Provided with a thread path groove. | B1109041F0B | 3 | 3.2 | D1524415BAA | Pressure of the presser foot: Standard value Needle: Standarad (#12~#18) |

| For light to medium weight materials | D1609415B00 | 1.9 | 1.15 | B1109041F0B | 3 | 3.2 | D1524415BAA (B15244120A0) |

Pressure of the presser foot: Standard value Needle: Standarad (#12~#18) Throat plate (B1109041F0B) provides higher durability than throat plate (B1109041F00). |

|

| For extra light weight materials | D1609415B0A | 1.2 | 1.15 | 11300308 | 3 | 3.2 | D1524415BAB | Needle: Thin (#7~#10) | |

DLN-5410NH-7

DLN-5410NJ-7

| Guage | FEED DOG | THROAT PLATE | PRESSER FOOT | Features in sewing | |||||

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

||||||

| Application | P/N | Needle hole |

Pitch | Remarks | P/N | No. of grooves |

Thickness | P/N | |

| Standard For heavy weight materials |

11322203 | 2.4 | 1.7 | Provided with a thread path groove. | B1109415H0B | 3 | 3.2 | B152404EA0 | Pressure of the presser foot: Slightly increase. Needle: Thick (#19~#23) |

| For heavy weight materials | 11321908 | 2*2.9 | 2 | A slot shaped needle hole | B1109415H0B | 3 | 3.2 | B1524041EA0 | Pressure of the presser foot: Slightly increase. Needle: Thick (#19~#23) |

| For extra heavy weight materials | 11322005 | 2.4*3.4 | 1.7 | Provided with a thread path groove. A slot shaped needle hole | B1109415H0B | 3 | 3.2 | B1524041EA0 | Effective when sewing the material which needs highlu tensed seams. Pressure of the presser foot: Slightly increase. Needle: Thick (#19~#23) |

| For heavy weight materials | 11322104 | 2 | 1.7 | B1109415H0B | 3 | 3.2 | B1524041EA0 | Pressure of the presser foot: Slightly increase. Needle: Thick (#19~#23) |

|

| For extra heavy weight materials | D1609415B0H | 2.4*3.4 | 1.7 | Provided with a thread path groove. A slot shaped needle hole | B1109415H0B | 3 | 3.2 | B1524041EA0 | Effective when sewing the material which needs highlu tensed seams. Pressure of the presser foot: Slightly increase. Needle: Thick (#19~#23) |

| For heavy weight materials | D1609415D0H | 2*2.9 | 2 | A slot shaped needle hole | D1109415D0H | 3 | 3.2 | B1524041EA0 | Pressure of the presser foot: Slightly increase. Needle: Thick (#19~#23) |