High-speed, high-quality line solution

Optimization

Before

Customer concerns

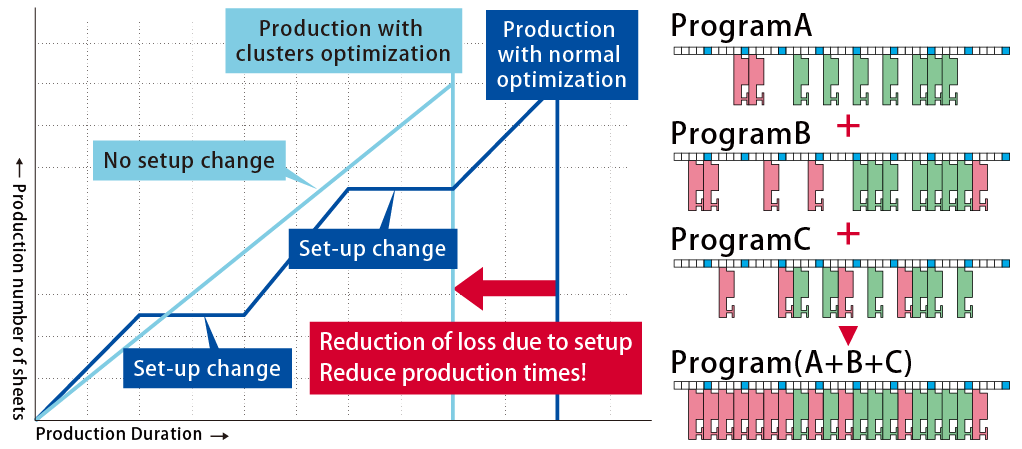

- Since it is a large variety of small quantity production, there are many setup changes, and the operation rate continues to be low.

- There is a lot of urgent interrupt production and production switching is taking longer.

- Estimation is desired because production finish times are not known.

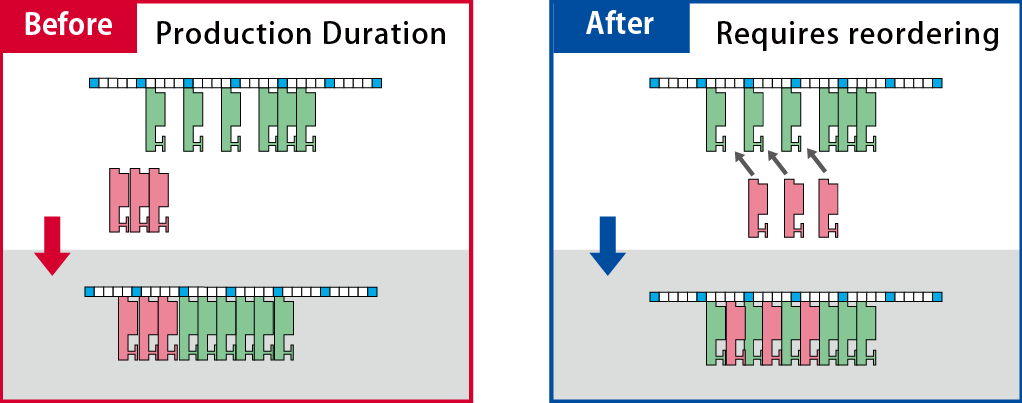

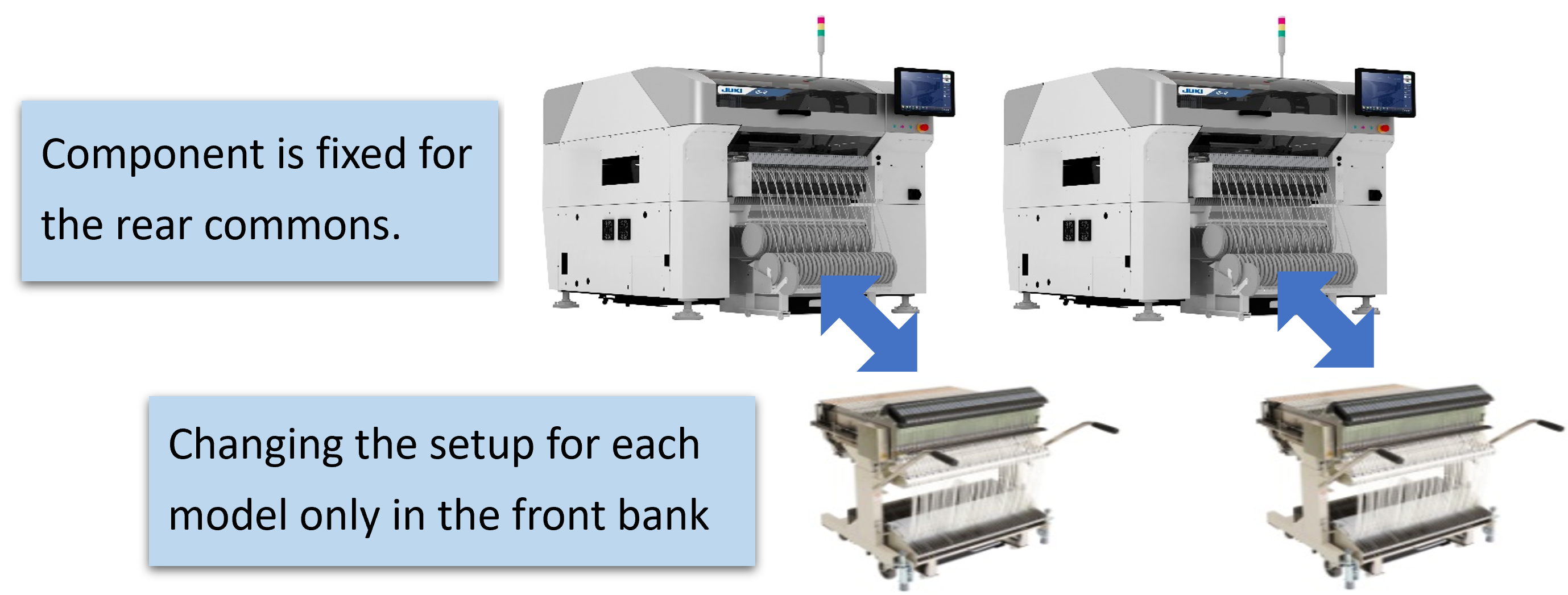

- Place and fix frequently used component together.

After

Customer feedback after introduction

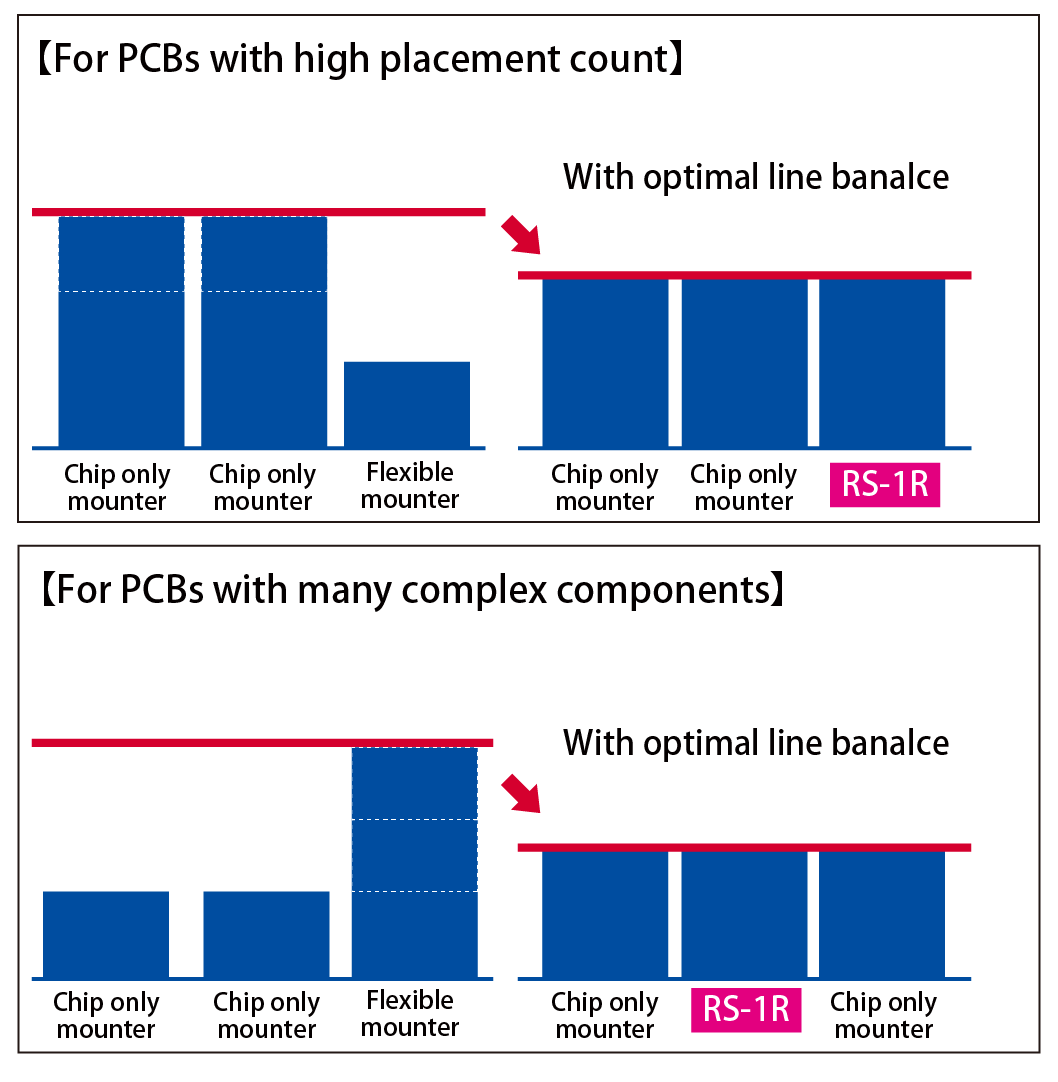

- Even when production item is changed, it is possible to respond by simply changing the program. Therefore, the line balancing is easy and the largest performance can be obtained.

- Production is improved by reducing the number of setup changes or creating a grouping with no setup changes.

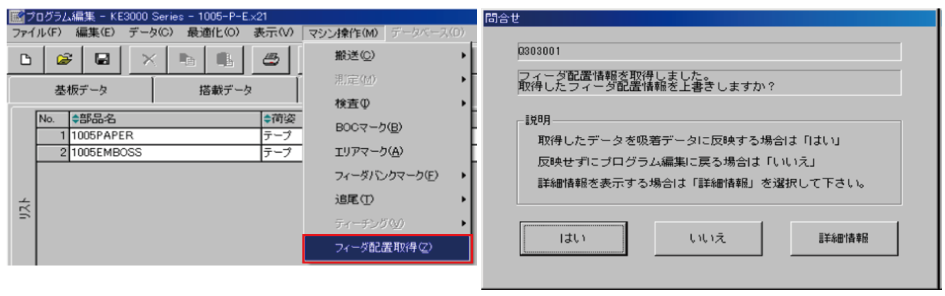

- The random feeder setup enabled feeder to be set to a vacant place and immediately started production.

- Production can be switched and production can be started in a short time.

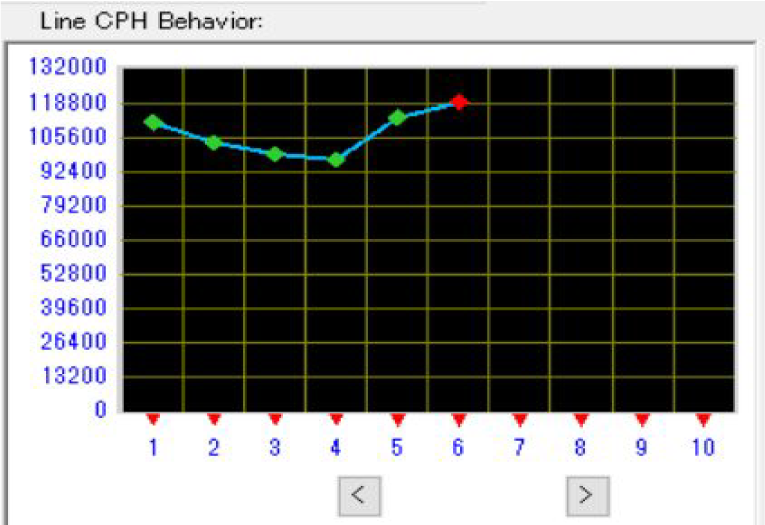

- The simulated function now allows you to estimate production endtimes.

- Since Feeder arrangement was registered and fixed in the database, production was enabled with the minimum set-up change. For example…

Introduction of related products

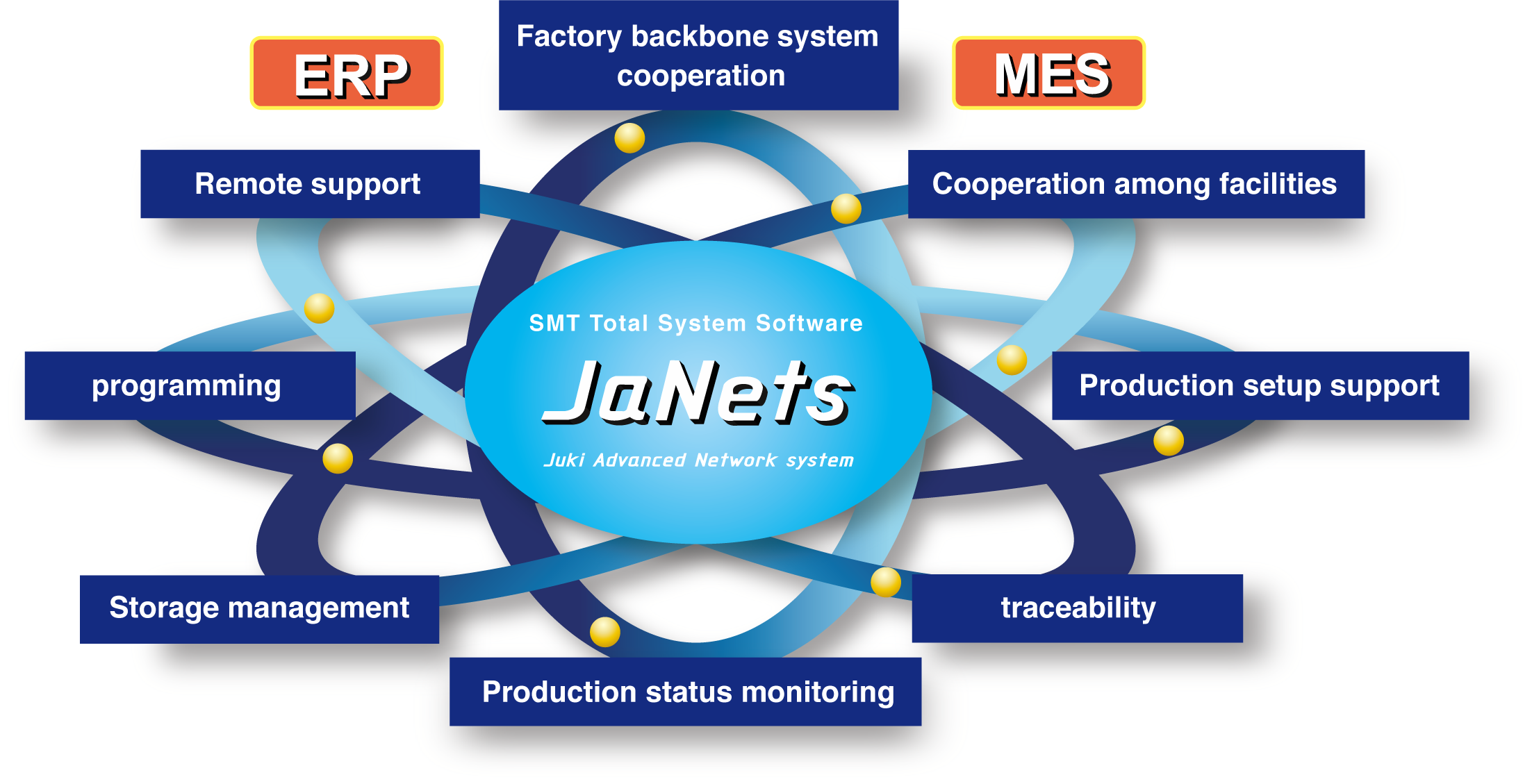

JaNets

SMT Total System Software