High-speed, high-quality line solution

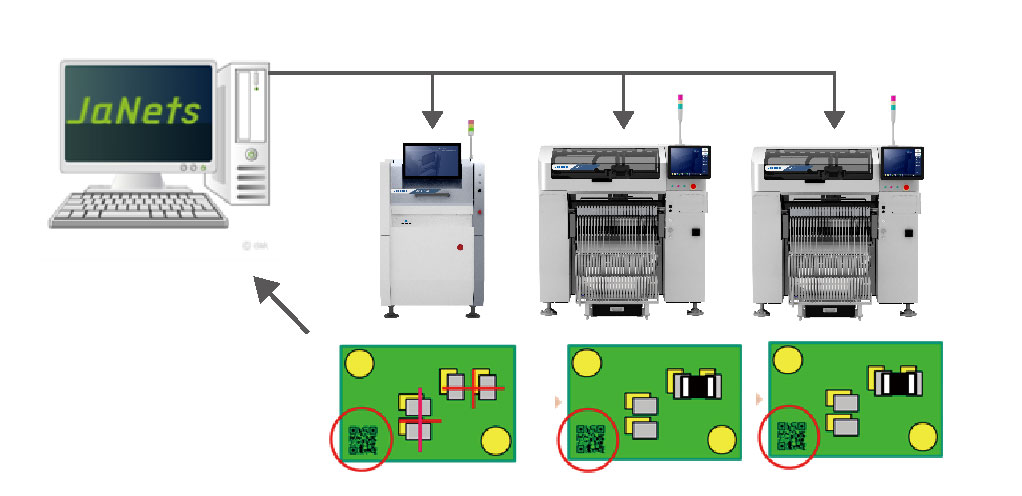

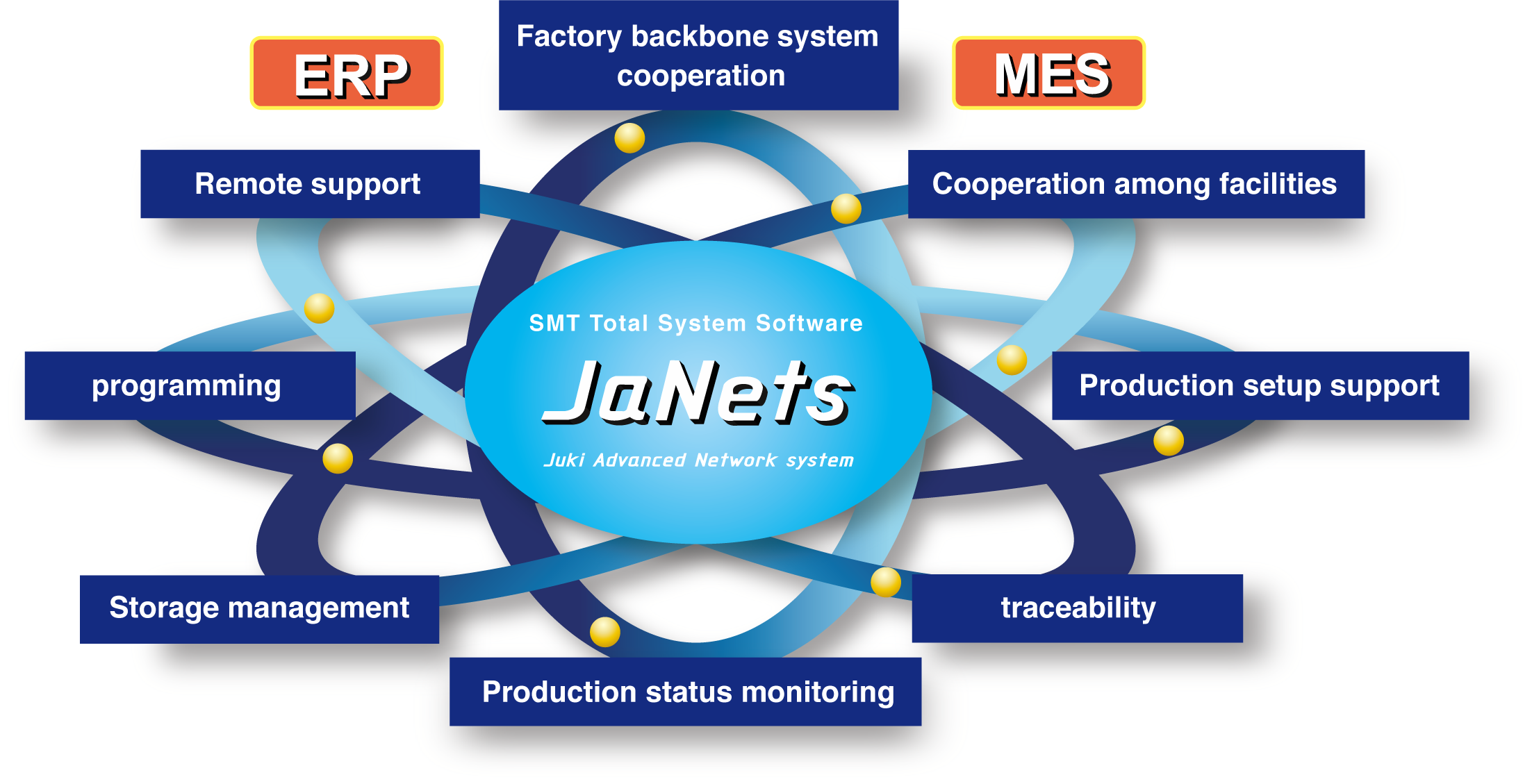

Cooperation among facilities

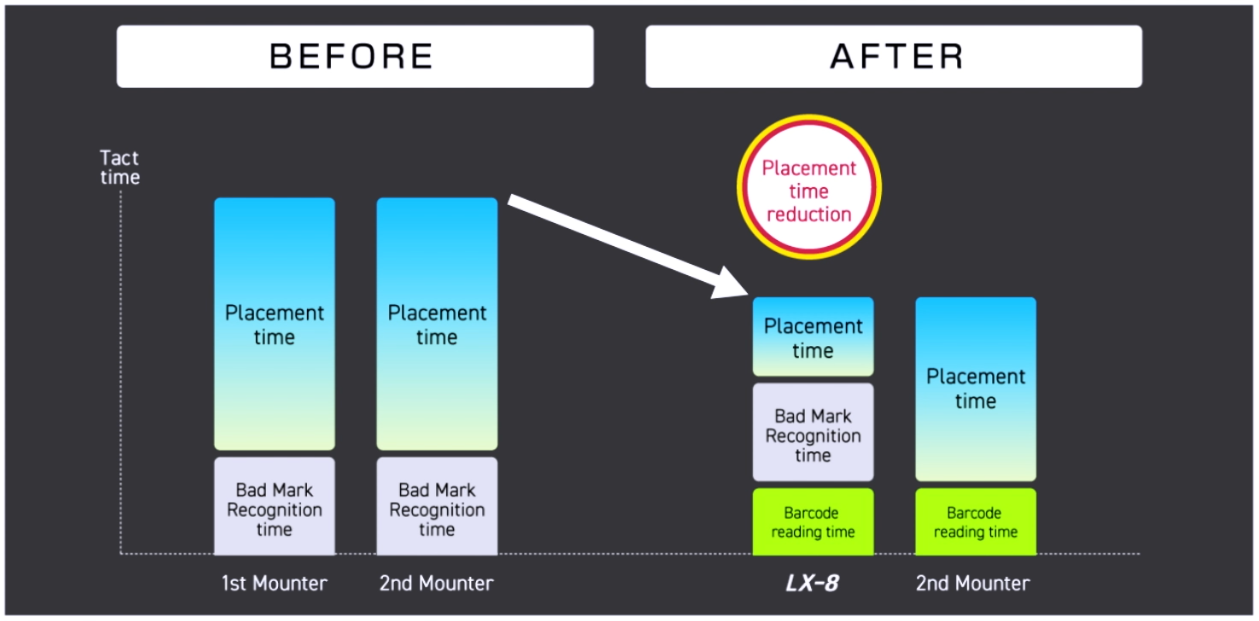

Before

Customer concerns

- When printing or mounting bad occurs, information is not transmitted between machines, and the countermeasure takes time.

- Bads after reflow do not fit

- Take time to recognize the bad mark

After

Customer feedback after introduction

- Printing misalignment in the inspection machine (SPI) can be corrected by transmitting the printing misalignment results to the printing machine, and it was possible to reduce the printing misalignment from the next board (Feedback) Stop

/Warning display/Cleaning/Printing position correction

- The inspection machine (AOI) feed back function minimizes the creation of defective boards.

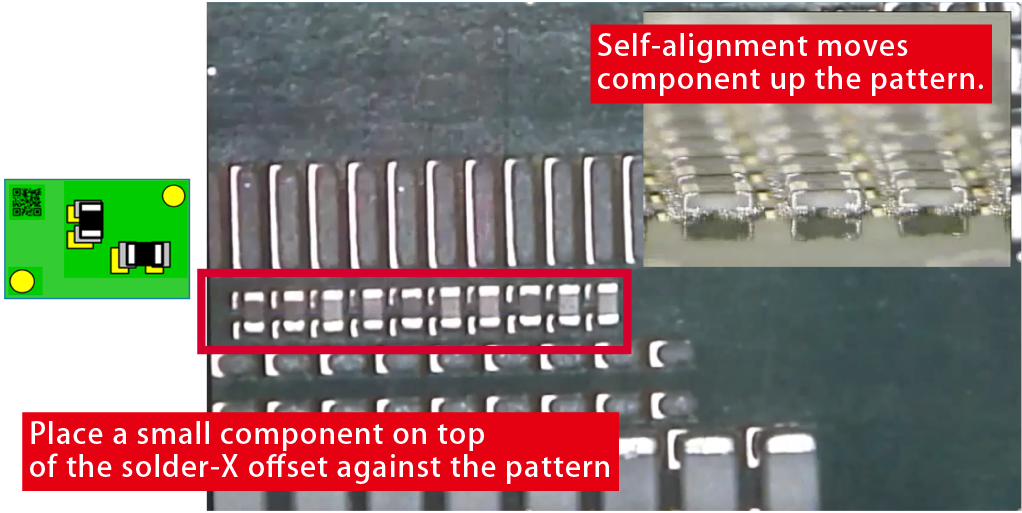

- Defects were reduced by feeding the misalignment in SPI to the mounter and place the solder position (Feed forward).

- The bad mark data of the pre-process equipment was linked to the post-process equipment to shorten the bad mark reading time. (Bad mark propagation)

Introduction of related products

JaNets

SMT Total System Software