Features

Speed

High speed of 50,000CPH

By positioning the laser sensor closer to the board and reducing travel time from pick-up to placement, the one-head mounter achieves an optimal speed of 50,000 CPH in its ideal conditions.

*Optimum condition

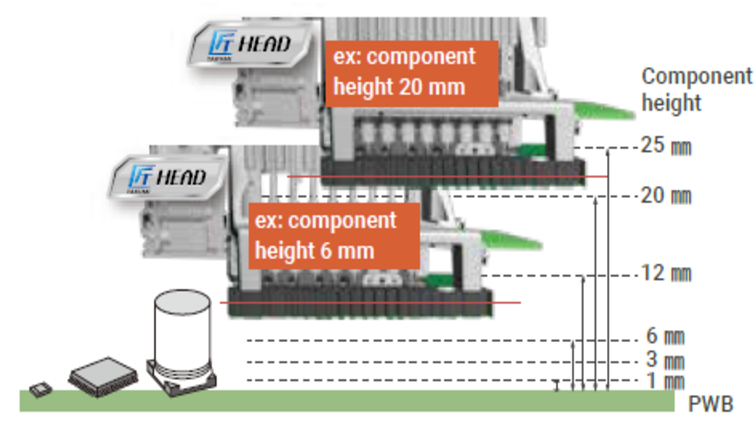

“TAKUMI Head” with adaptive sensor height

The height of the laser sensor on the “TAKUMI Head” automatically adjusts based on the height of each component being placed,

allowing precise pick-up and placement.

This 8-nozzle “TAKUMI Head” accommodates components of varying heights, from the smallest to the largest, ensuring optimal

speed and accuracy.

Component height can be selected from six levels: 1, 3, 6, 12, 20, and 25 mm.

“TAKUMI Head” which changes with the height of the sensor

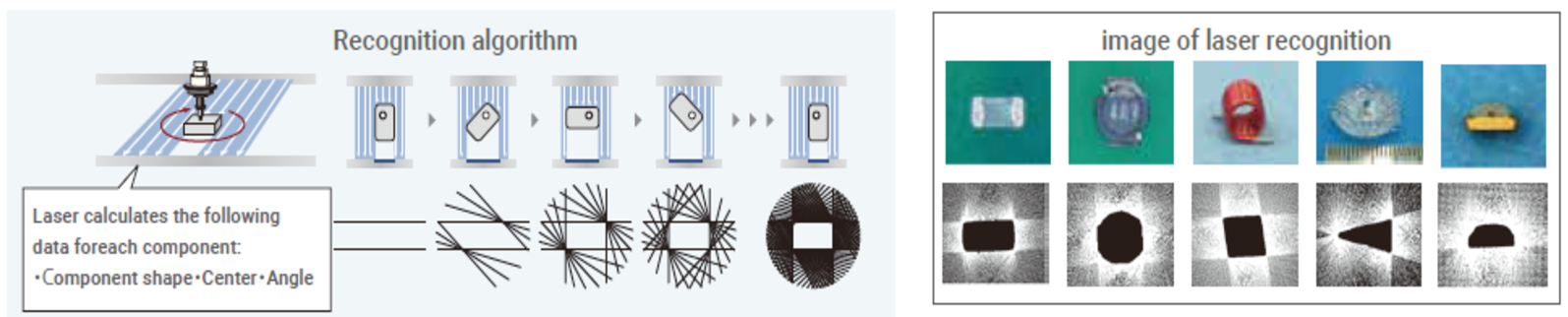

Realizes high-speed, high-precision recognition with JUKI’s proud laser-recognition technique

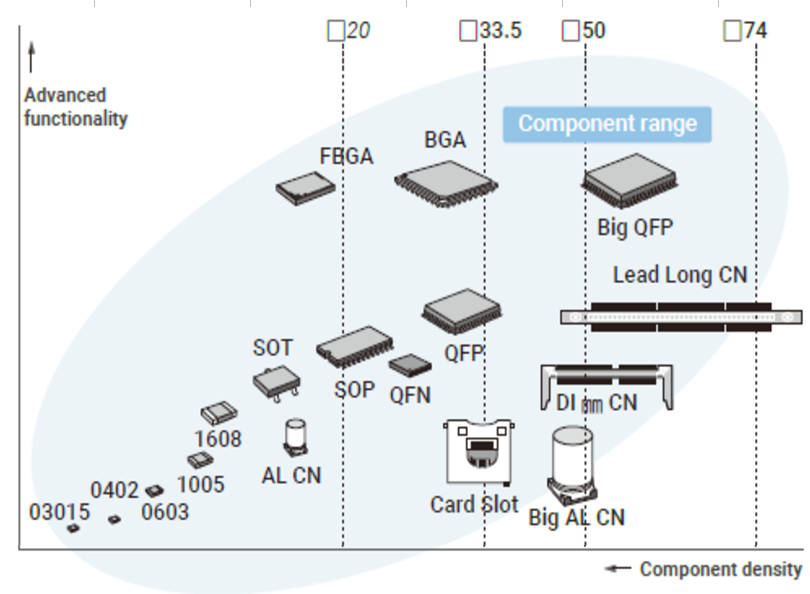

JUKI’s laser-recognition technology enables fast, accurate identification of various component shapes, including BGA, SOP, and QFP, ranging from as small as 03015 to sizes up to 50 mm square. This laser-recognition system ensures stable recognition and placement, unaffected by variations in electrode shape or surface gloss. Additionally, creating component data is simplified, allowing for quick integration of new components.

Flexibility

Wide component range

Supports components from sizes as small as 03015 up to 74 mm square or 50 mm x 150 mm, with placement heights accommodating components up to 25 mm.

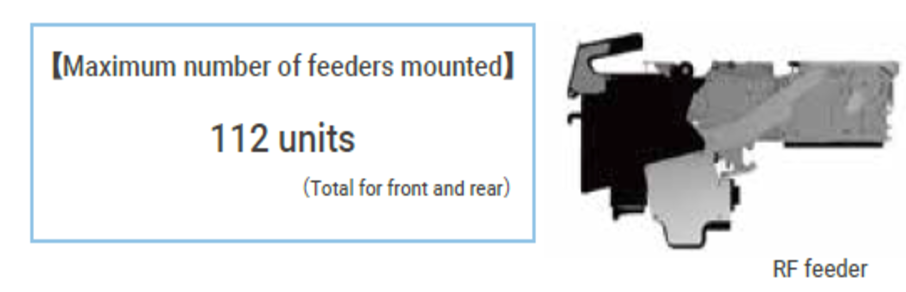

Up to 112 feeder mounting for flexible and efficient production

The compact, lightweight, and slim design of the RF feeder supports up to 112 feeder units (front and rear combined),

enabling high-efficiency production.

This setup is ideal for multi-product, small-lot production with minimized setup times.

* When RF feeder (RF08AS) is used.

Quality

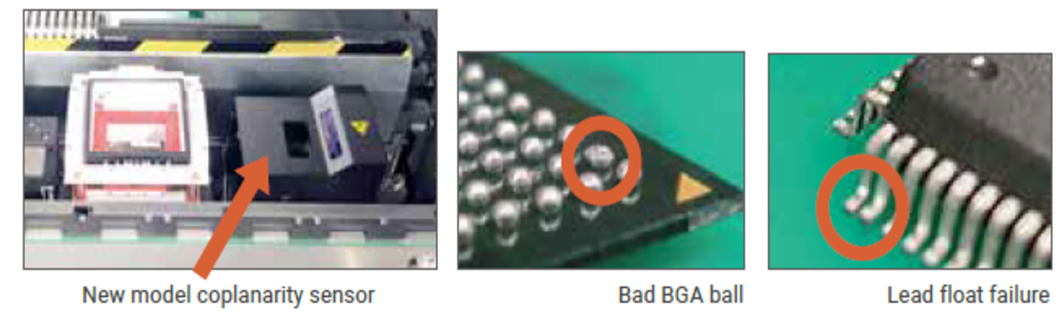

NEWAdvanced high-precision coplanarity new model

Detects lead floating and BGA ball deformation to prevent the placement of defective components. High-precision coplanarity checks enhance product reliability.

Specification

| Fast Smart Modular Mounter RS-2 | |||

|---|---|---|---|

| Board size | Minimum | 50 mm ×50 mm | |

| Maximum | 1 buffer | 800 mm ×370 mm | |

| 3 buffers | 410 mm×370mm | ||

| Allowable board weight | Max. 3 kg | ||

| Substrate thickness | 0.3~6.0mm | ||

| Component height | 25 mm | ||

| Component size | 03015-50 mm x 150 mm (1 x 3 segment recognition) x □74mm (2 x 2 segment recognition) | ||

| Placement speed | Optimum | 50,000CPH | |

| IPC9850 | 32,000CPH | ||

| Placement accuracy | ±35μm(Cpk≧1) | ||

| Feeder inputs | 112 products*1 | ||

| Power supply | Three-phase AC200V (Standard Type)/Three-phase 200 VAC to 415V (When the Type with Transformer is Selected) | ||

| Apparent power | 2.2 kVA | ||

| Operating air pressure | 0.5±0.05 MPa | ||

| Air consumption | When using a vacuum generator: 200L/min (standard), when using a vacuum pump: 50L/min (optional) | ||

| Machine dimensions(WxDxH)*2 | 1,500 mm ×1,686 mm ×1,450 mm | ||

| Mass(approximately) | 1,630kg | ||

*1 Using RF(RF08AS) feeders

*2 D dimension does not include the front operation monitor. H dimension does not include signal tower.

Contact