Pickup and Placement as the

“Eyes of the Mounting Process”

Supported Model

KE-2070/KE-2080/KE-2080R/FX-3R/KE-3010/KE-3020V/KE-3020VR

Catalog download ContactFeatures

Defect Cause Analyzing Tool

Captured images will be stored in a database. When a defect occurs, the database can be searched to retrieve the captured image data so that analysis of the defect cause can be easily carried out. In addition, a full range of analysis supporting functions is provided including a Movie Mode and a Digital Zoom Function.

Component Presence Verification

By comparing the images captured before and after the component placement, it is possible to judge whether the component is present or absent.

Database Management

The captured images and the placement machine information are stored in a database. By selecting a specified database from a backup file, it is possible to display previously stored data.

Setup Assistance

When starting production with a new placement machine type, the master image showing normal product placement can be displayed alongside the image captured during manufacturing and trial placement. This allows verification of the placement condition to be easily carried out and shortens the setup time of the new placement machine.

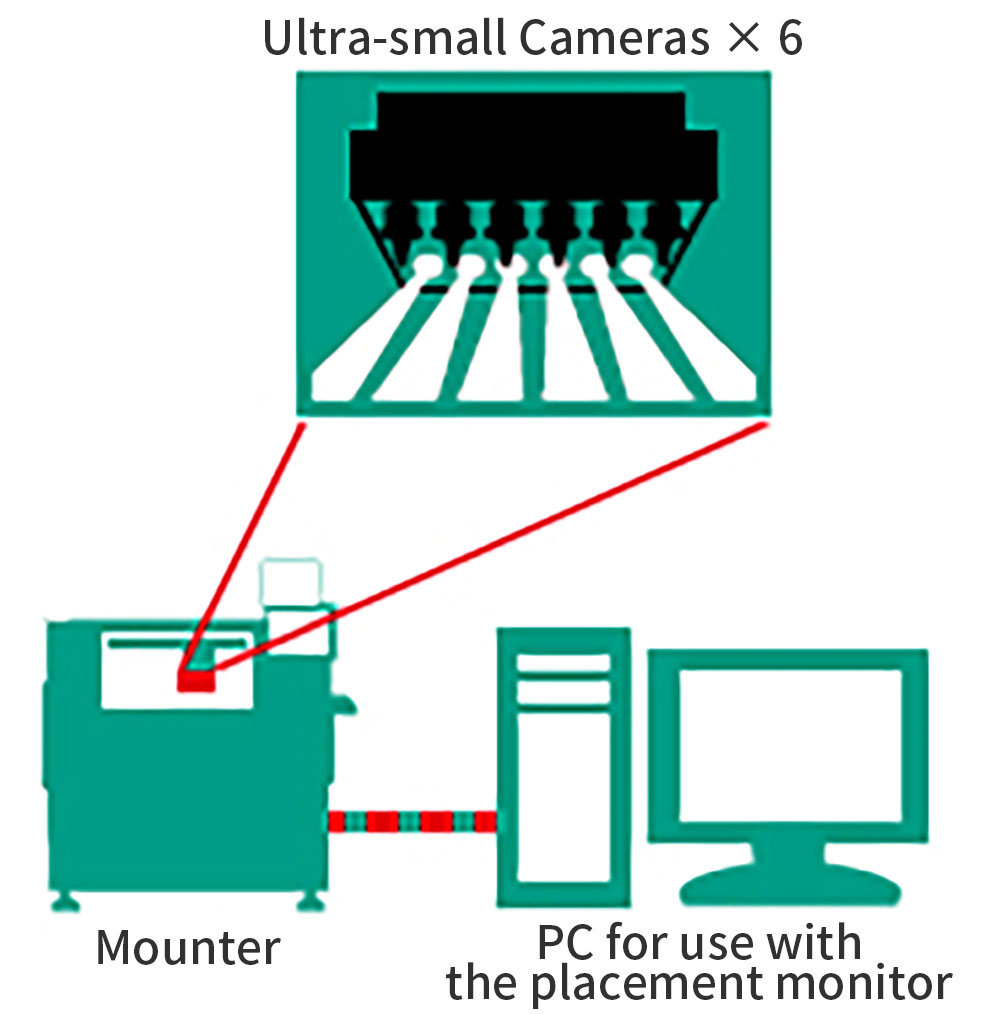

What is”Placement Monitor”?

By attaching newly developed, ultra-small cameras directly to the placement machine head, imaging and storage of the pickup and placement of each component can now be carried out in real-time. When a defect occurs, cause analysis can be carried out visually by the operator based on the stored image data.

Specification

< Basic Specifications>

| Supported Model | KE-2070 / KE-3010 | KE-2080 / KE-2080R / KE-3020V / KE-3020VR |

FX-3R | |

|---|---|---|---|---|

| Camera field of view | 12.0×7.5mm | 10.3×7.3mm | 10.3×6.1mm | |

| Estimated data size of captured images | Capacity consumption per image | Approximately 200KB(*.bmp), 50 ~ 120KB(*.png) (Monochrome) | ||

| Capacity consumption per hour | Approximately 18.3GB | Approximately 16.7GB | Approximately 52.8GB*4*5 | |

| Component presence or absence judging | Component size | Min.0.4×0.2mm ~ Max.5.0×5.0mm | ||

| Component height | Max.2.0mm | |||

< Computer Specifications>

| CPU | 2.66GHz or faster (Intel Core |

|---|---|

| Memory | 4GB or more |

| HDD Capacity | C drive: 750GB or more (SATA) D drive: 2.25TB or more (SATA, RAID 0) (Create C drive and D drive; create the data storage area in D drive.Note) *1*2 |

| Chipset | Intel X58 chipset or the equivalent |

| DVD-ROM Drive | 1 or more unit |

| USB port | 1 port or more |

| LAN port | 1 port or more |

| Monitor resolution | 1024×768 pixels or greater |

| Expansion slot | 1 PCI bus slot *3 |

| OS | Microsoft Windows 7 Professional 32-bit |

*1 External hard Drive D cannot execute the system.

*2 HDD capacity of the recommended specifications is approximately 1.3 M images (*.bmp) (equivalent to 2.6 M components).

*3 An IEEE1394a expansion card specified by JUKI is to be connected to the slot for communication with a mounter.

*4 It is a total capacity when taking four images with four placement monitors installed.

*5 Five-image mode is selectable. Feel free to contact us for more details.

* Microsoft Windows 7 is a registered trademark of Microsoft Corporation in the United States and other countries.

* Intel Core is a trademark of Intel Corporation in the United States and other countries.