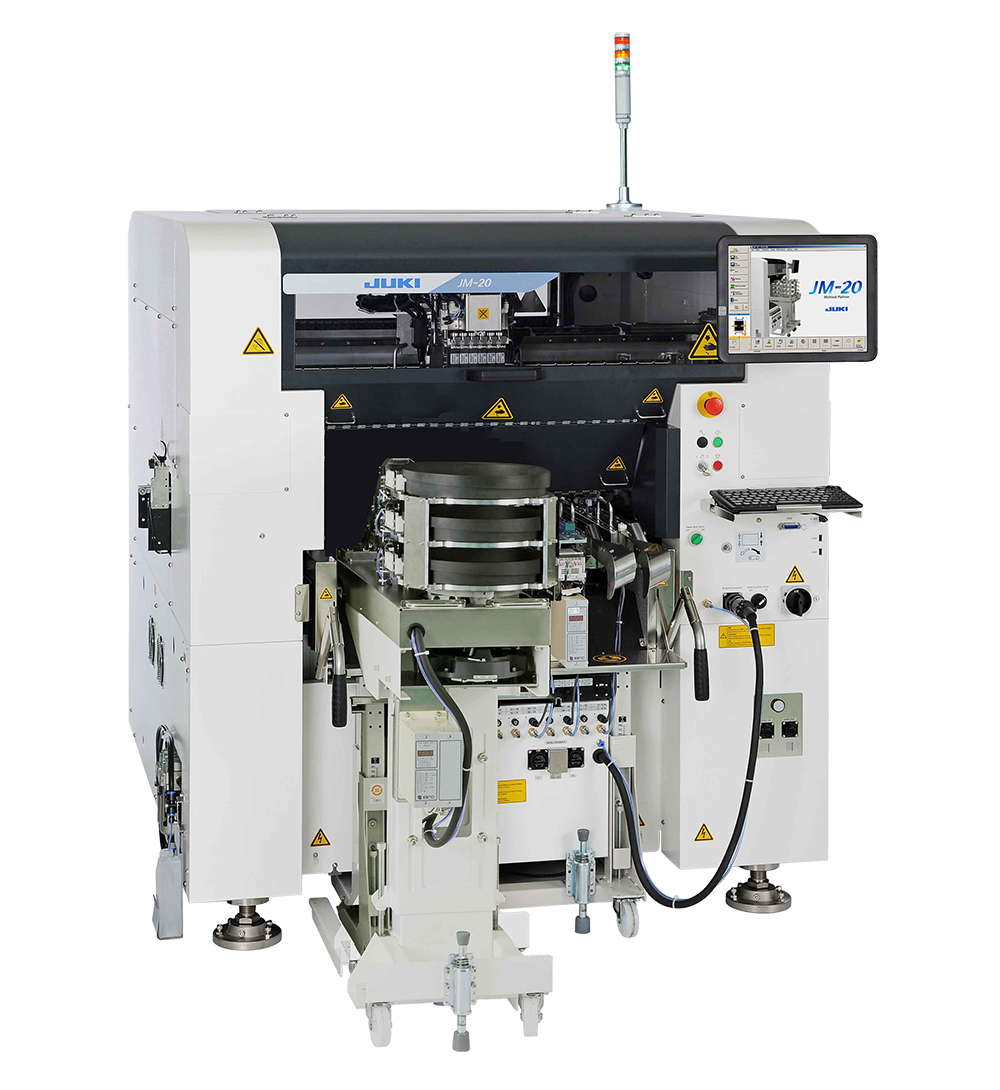

Multitask Platform

JM-20

Higher quality and labor savings by automating manual insertion.

Advanced model for larger/heavier components and larger boards

Features

- Laser sensor for lead detection

- Wide variety of feeder types

( Feeders can be customized for specific components ) - Lead 90 degree bend function

- Lead Correction Unit

Specification

| Multi Task Platform JM-20 | ||||

|---|---|---|---|---|

| L-size board | XL-size board | |||

| Board Size | Single Clamp | 410×360mm | 410×560mm | |

| Double Clamp | 800×360mm | 800×560mm | ||

| PCB Weight | max.4kg | |||

| Component Height | 28mm | ○ | ||

| 55mm | ○ | |||

| Component Size | Laser recognition | 0603 ~ □50mm | ||

| Vision recognition *1 | 54mm view camera | □3mm ~ 50mm | ||

| 27mm view camera | 1005 ~ □24mm | |||

| Insertion Speed | Vacuum (JUKI Condition) *2 | 0.8 sec/parts *3*4 | ||

| Placement Speed (SMT) | Chip (Optimal) | 15,500 CPH *3*4 | ||

| IC | 4,200CPH *3*4 | |||

| Placement Accuracy (SMT) | Laser recognition | ±0.05mm(3σ) | ||

| Vision recognition *1 | ±0.04mm | |||

*1 Optional specification.

*2 Under JUKI condition

(Component type: aluminum electrolytic capacitor (φ8㎜), Supply device: MRF-S x 2; Two points simultaneous pick x 3 times/cycle (6 nozzles), Axis speed: Default value for component type “Insertion component” “INS electrolytic capacitor (JM-20 only)”.

*3 Excludes time for PWB conveyance and mark recognition.

*4 For component height 28mm.