Automatic Assembly Solution

Case1. Reduces manual labor required by 50%

Overview

Process automation

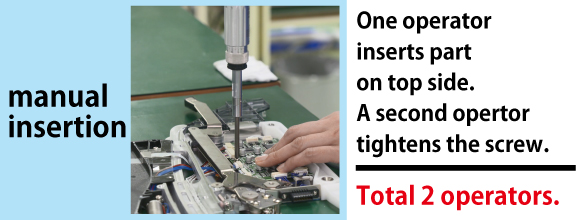

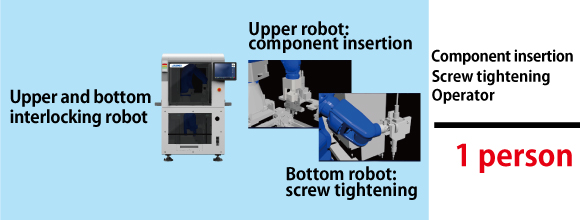

Top side: insetion ⇒ Bottom side: screw tightening

Using robots replaces 2 manual processes

Top side: insetion –> Bottom side: screw tightening

After the introduction of automation improvement

Benefits

- Simpler process

・Automation and labor savings - Easy operation

・Faster setup

・Less operator trainning

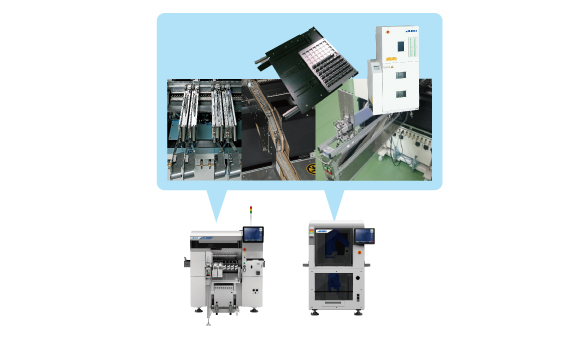

Case2. Reduction of pick and place machines needed

Overview

Aging insertion machines ⇒ Replace with flexible insertion platforms

Using dedicated AI machines. Multiple types needed (radial, axial)

Flexible insertion machine. Wide range supported on 1 machine.

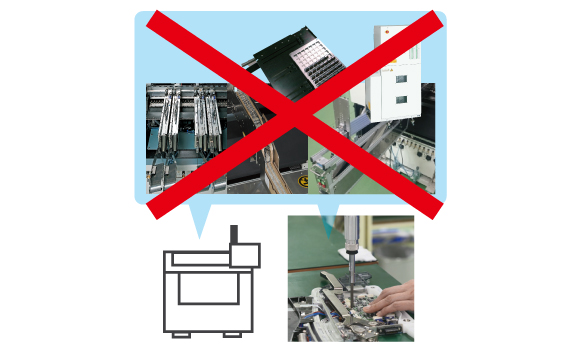

Auto Insertion machine :

External setup is not possible

General-purpose insertion machine:

Bucket-type parts can be set up externally

AI-dedicated facility : Large facility-Split production not possible

General-purpose inserter: Split-production by external setup

Benefits

- Strengths of General Purpose Insertion Machines

・Supports a wide varity of component types in one platform - Single model covers a wide range of production requirements

・Use of off-line feeder setup: Significantly reduces setup time

・Reduced floor space due to fewer total machines

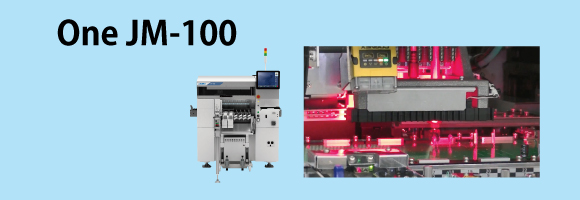

Case3. Full automation reduces new product introduction time

Overview

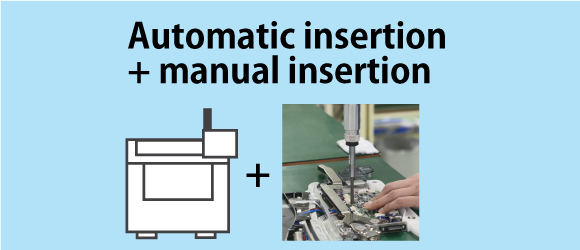

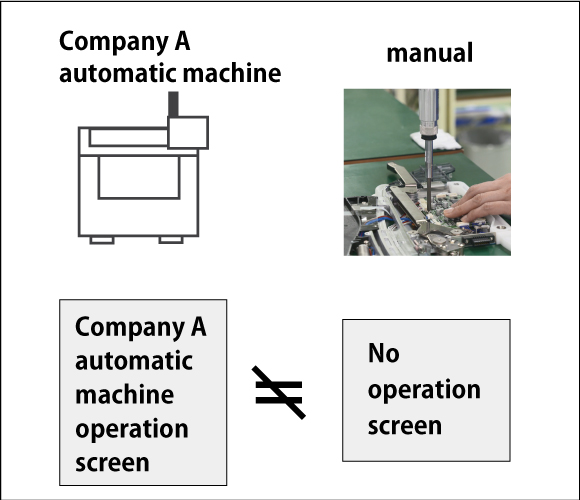

JM Series + MR-01 can fully automate lines that currently have a mix of automation and manual assembly

Manual processes required in-line with automatic machines

MR-01 replaces manual assembly

Completely manual work

Production lines using a common platform capable of a variety of assembly work.

Dedicated insertion machines cannot support many components

Standard feeders and tooling supports a variety of parts

All machines required for every job, regardless of part types

Benefits

- Full process automation

・Shortens setup time and reduces manpower - Use of flexible assembly machines

・Maximizes use of assets (common feeders and nozzles)

・Reduces capital investment