Preventive maintenance

Before

Customer concerns

- Cannot manage maintenance timing

- Bad operation due to poor maintenance

- The product was maintained or not managed.

After

Customer feedback after introduction

- By visualizing the maintenance timing, preventive maintenance can be carried out without deviating from the timing, and the defect rate is reduced.

- Maintenance schedule of various equipment and setting of work type can be carried out, so that equipment can be maintained in good condition.

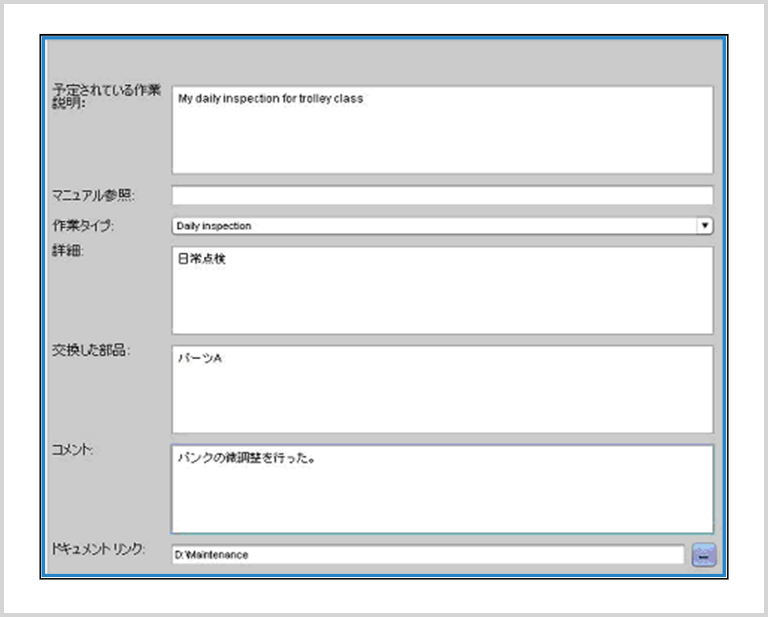

- Inspection history also became known

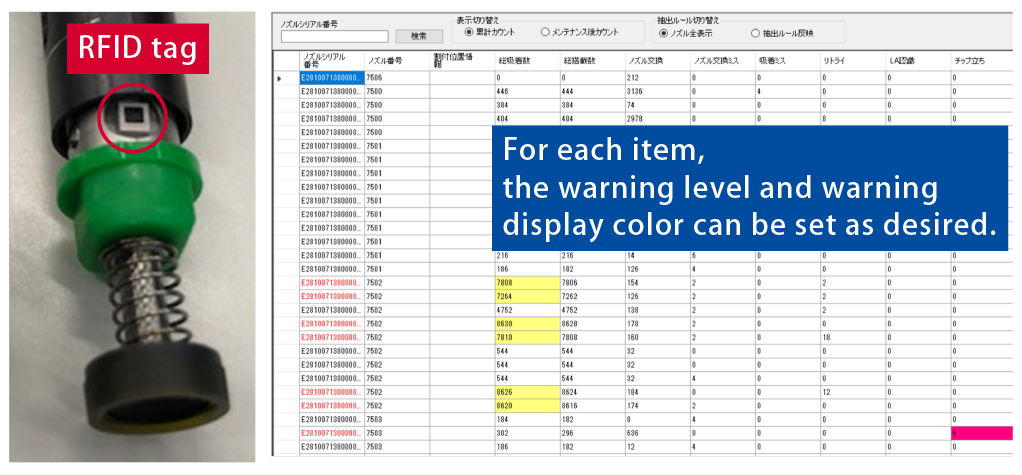

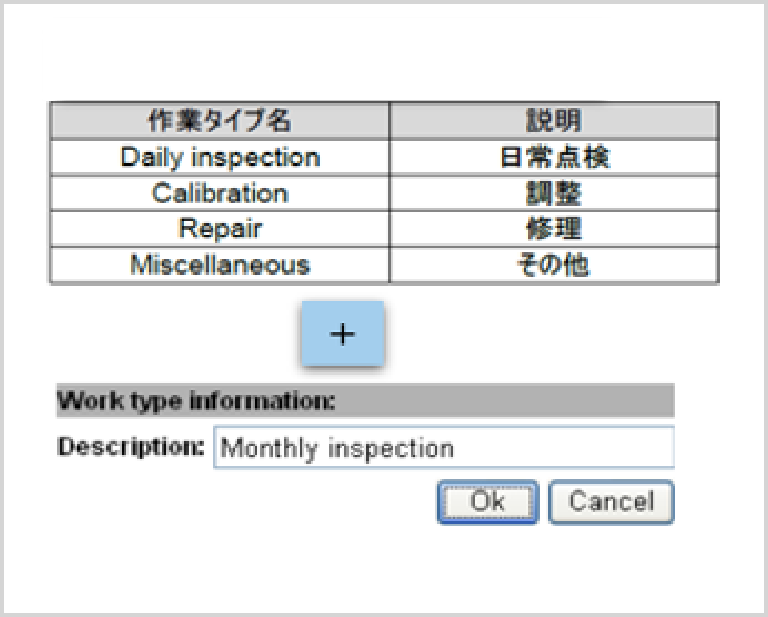

- Work type (can be added arbitrarily)

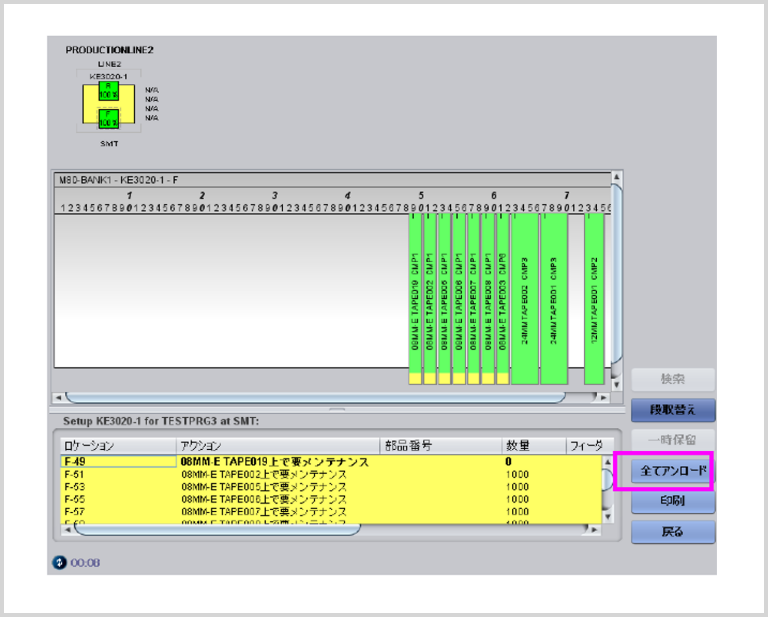

- Job setup window warns you of maintenance-related equipment.

- Inspection history screen

- The timing of the nozzle replacement was clarified by the individual control using RFID nozzle.

- This enables ratio of pick-up to be replaced prior to dropping, enabling preventive maintenance and high-level production.