Post-process automation solution

Process improvement

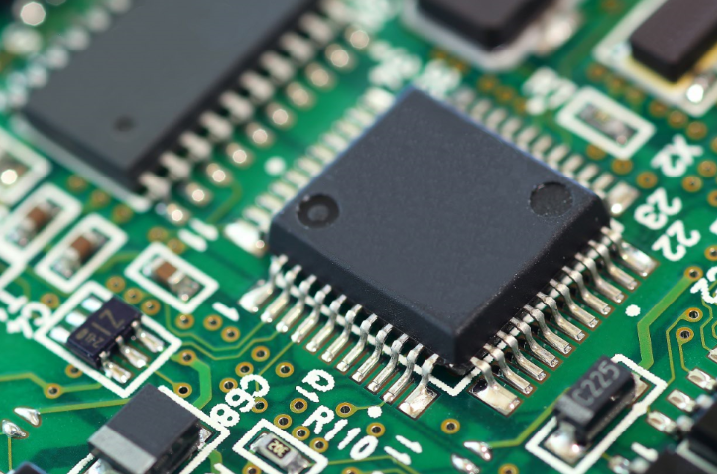

Before

After

Customer feedback after introduction

- Compatible with insertion parts as well as surface mount parts, and highly versatile

- We were also able to deal with hand-inserted parts that could not be handled by automated machines (AI machines).

- Process improvement was also realized because of high versatility.

- Since the modular system is similar to the mounting machine, it is possible to improve the productivity by connecting them.

- Batch replacement of the parts mounted on the bogie reduced the line stopping time at the time of model switching.

- The line length became shorter because the machine was highly versatile and multiple parts could be inserted by one unit.