High Precision Solder Paste Printer with

excellent cost performance

Features

Optimum-Paste Control (OPC) – Get ready for lights – out manufacturing

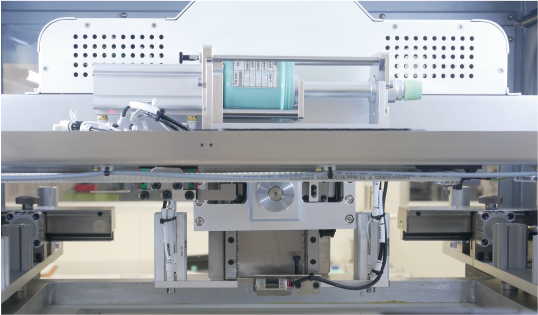

Auto solder paste replenishment system

The solder paste is automatically dispensed across the entire squeegee length, maintaining at 15 mm rolling diameter, adopting the common 500 grams’ solder paste jar. Completely eliminates the wastage of solder paste overflowing to the sides of squeegee.

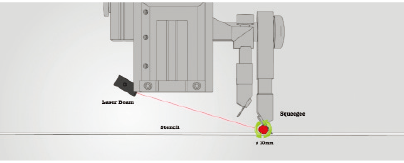

Solder paste rolling diameter monitoring system

Tracing solder paste rolling diameter in real time and trigger the auto dispensing if it falls below 10 mm. Completely eliminate insufficient solder paste on stencil and keep the paste rolling speed within optimum range to achieve best printing result.

Quality Print Control (QPC) – Nothing is more important than a GOOD print

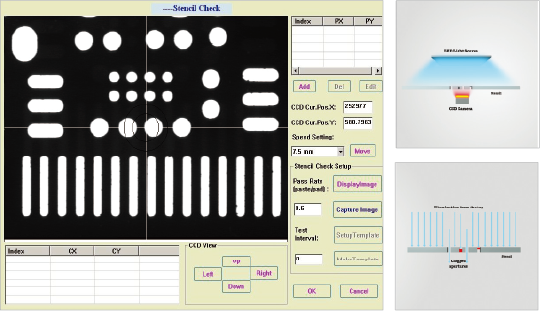

Stencil aperture inspection system

Using panel light installed at the top and CCD camera below to inspect stencil apertures. It automatically detects the clogging of stencil apertures to eliminate poor quality stencil being used, ensure quality printing right from the start.

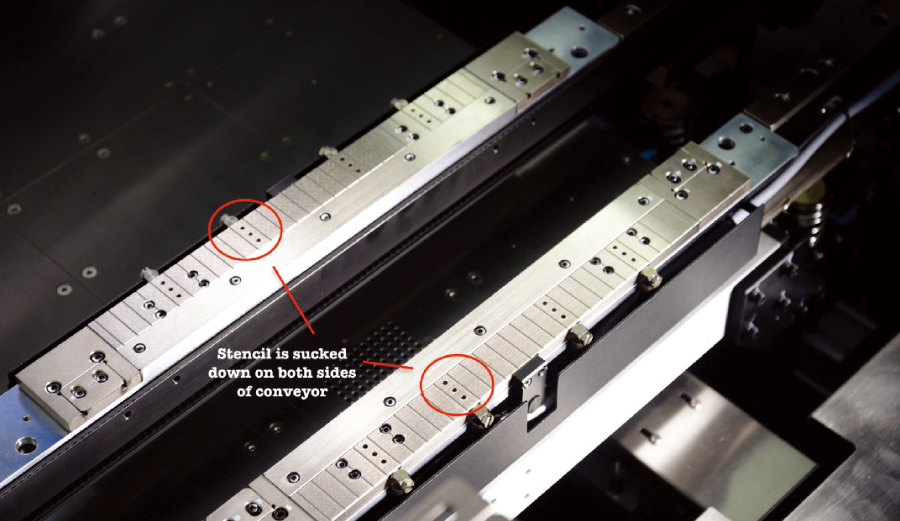

The Stencil lock & PCB clamper

The Stencil lock sucks the stencil firmly on both sides of the conveyor during printing cycle. To eliminate stencil vibration by having firm contact with PCB. The PCB clamper is a combination of retractable top clamp and motor controlled side clamp, uniquely designed by GKG (patented). With these standard features, all of today’ s available and challenging substrates can be securely clamped and print to the highest quality.

SPI Close-loop connection

With SPI close-loop system, machine will automatically adjust and correct the print deposits based on the feedback given with regards to poor printing quality. This will facilitate improved print quality and production efficiency, by forming a complete printing feedback system.

Movie

Specification

| PCB size | 50mm×50mm – 510mm×510mm |

|---|---|

| Cycle time | 8.5 sec+Printing time |

| Positioning accuracy | ±10μm(6σ) |

| Stencil frame size (L x W) | Adjustable, 470 x 370 mm to 737 x 737 mm |

| Power supply | Single-phase AC200V~240V 50/60Hz |

| Air supply | 0.4 ~0.6MPa/cm² |

| Dimension (excluding signal tower) |

1,240 (L) x 1,560 (W) x 1,490 (H) |

| Machine weight | 1,200kg |