Multitask Platform

JM-50

Reliable, high quality automatic insertion

with unmatched value

Features

- Ideal for high-mix low-volume production

- New, flexible feeders increase component range providing superior productivity and faster changeover

- Huge variety of applications

- New Mini Chuck Nozzles support a wide range of components, reducing cycle time, decreasing tooling costs, and simplifying programming

- Largest installed base thanks to high quality and unmatched reliability

|

|

|

|

2071 |

2070 |

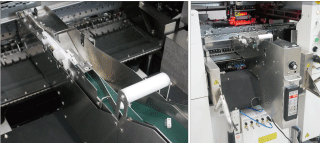

General-purpose bulk feeder is ideal for loose parts |

|

Mini chuck nozzle |

||

Movie

Specification

| Board size | Single clamping | 50×50㎜~410×360㎜ |

|---|---|---|

| Double clamping | 50×50㎜~800×360㎜ | |

| PCB weight | 2kg | |

| Max. component height | 30㎜ | |

| Component size | 0603~□50㎜ | |

| Power supply | 3-phase AC200~415V | |

| Apparent power | 2.2kVA | |

| Circuit breaker | Standard | |

| Air consumption | 81L /min | |

| Conveyor height | 900㎜、950㎜ | |

| Machine dimension (WxDxH) | 1,454×1,505×1,450㎜ | |

| Mass (approximately) | 1,300kg | |

Options

| Rear side operation unit | ● | |

|---|---|---|

| 950mm conveyor height (SMEMA) | ● | |

| 3D Vision centering system | ● | |

| Lead correction jig | ● | |

| Feeder trolley | ● | |

| Keyboard | ● | |

| Automatic conveyor width adjustment | ● | |

| External signal tower | ● | |

| Super foot | ● | |

Feeder capacity*¹

| Bankd | Max,SMT tape feeders (8mm) |

Radial feeder | Axial feeder | Stacked stick feeder |

General purpose bulk feeder MVF |

Tray holder | TRSSNK Number of trays |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| MRF-S | MRF-SN | MRF-L | MAF-S | MAF-L | Full | Half | |||||

| 18mm pitch | 56 | 18 | 18 | 14 | 14 | 10 | 10 | 5 | 1 | 2 | 40 |

| 12mm pitch | Not applicable | 16 | 18 | 12 | 16 | 12 | 12 | 6 | 1 | 2 | 40 |

*1 Max quantity of feeders for given type.

*2 Head height may be restricted depending on feeder location.

Contact