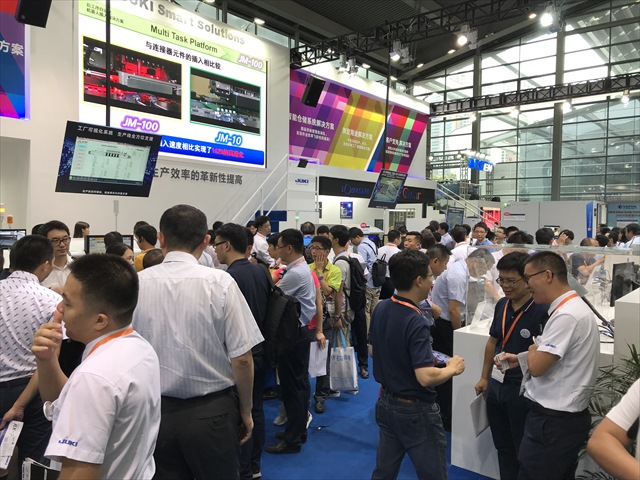

Exhibited at the Nepcon South CHINA 2018

We participated in the Nepcon South CHINA 2018 held in Shenzhen, China (Shenzhen Convention &Exhibition Center) from August 28 to August 30, 2018.

At this exhibition, we proposal five system solutions that will improve production efficiency throughout the plant. The five system solutions include high-output high-speed mounting system solutions, which combine the new products RX-7R and RS-1, and equipment and systems centered on the integrated mounting system software JaNets, under the theme “JUKI Smart Solutions: Innovative Production Efficiency Improvement in the Factory as a whole.”

In particular, a large number of customers visited the exhibition areas of “Storage System Solutions” for efficient parts supply/control and automation, “JM-100” for increasing productivity and automation in the post-process, and “Robot Insertion System Solutions for Screw Tightening”

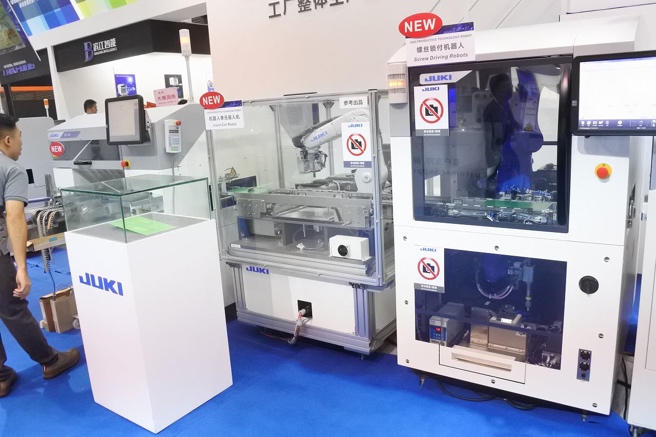

1. Post-process automated robot insertion system solution

We have proposed JUKI robot insertion technologies, such as the JM-100, a new product that automations the post-process, and the JM-100, a screw-tightening robot that realizes the component insertion process and the screw-tightening process in one unit.

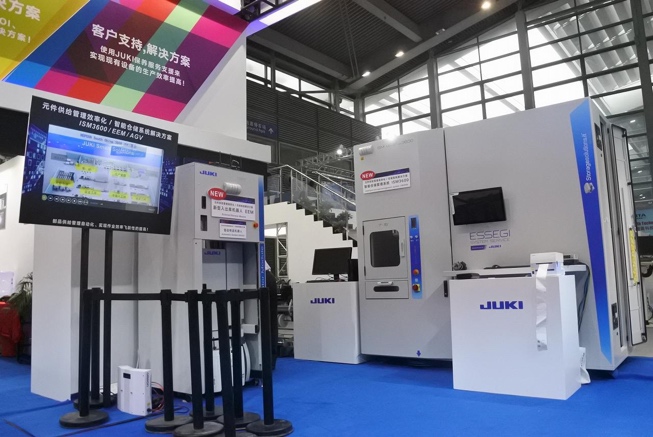

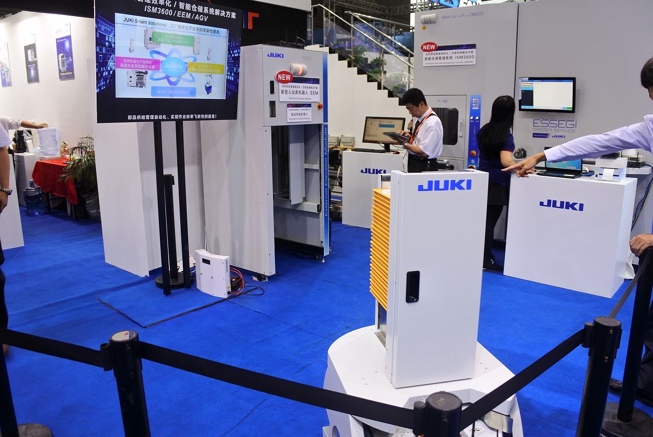

2. Storage System Solutions for Efficient Supply and Control of Parts

We conducted demonstrations of the delivery of parts to post-process lines from the delivery and delivery of automated parts using the ISM3600 automated warehouse and the new EEM+AGV.

Automatic parts unloading from ISM and automatic transportation by AGV are being seen in the near future.

3. Variable Variable Efficiency High-Speed Mounting System Solution

The new product RX-7R, which combines RS-1 with RS-1 to improve productivity in variable-volume production, and the latest high-speed mounting line were displayed.

“Inter-Facility Cooperation Functions” to improve quality/productivity through system-based cooperation between JaNets and facilities,

We have also proposed a variety of system solutions, including a visualization system that supports optimization of production progress, quality status, production status, and operational status, and a core system that realizes the smartness of the factory.

4. Measurement application solution

This paper introduces an example of realization of precision measurement inspection of precision parts and in-vehicle parts by applying the algorithm of image inspection cultivated in the appearance inspection of electronic boards.

We have proposed the “RV Series” for a variety of measurement applications.

5. Customer support solutions

The RS-1 and RX-7R mounterheads were displayed in this corner.

We have also proposal the importance of facility maintenance through maintenance parts kits, nozzle washers, and nozzle inspectors, as well as improvement of stability, quality, and problem-solving through JUKI customer support.