We help customers in manufacturing industries manufacture their products.

We started a “contracted development and manufacturing business” in 2016 to help customers in the manufacturing industry achieve the enhanced production capacities using techniques developed by JUKI for parts manufacture and assembly for industrial sewing machine products.

Customers in the manufacturing industry

- These customers would like to outsource the precision processing of parts.

- These customers would like to outsource production on a “unit” basis covering the stages of processing, paint, and assembly.

- These customers would like to outsource development, commercialization, and mass production.

The Ohtawara plant develops and manufactures products on a contract basis.

JUKI’s multi-selection manufacturing

We offer customers the processes that they need and demand.

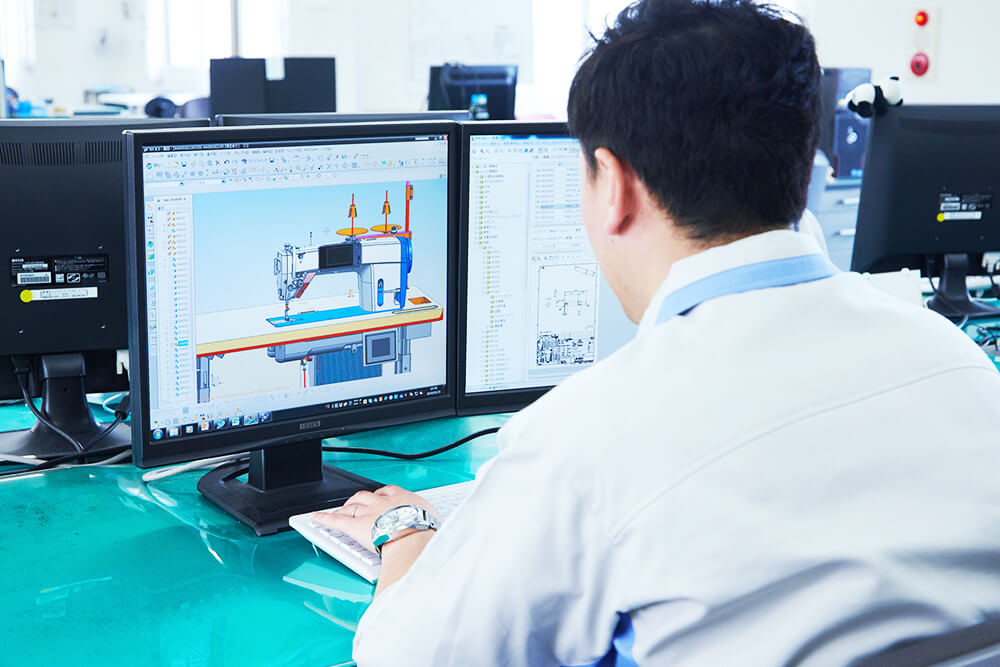

Development design

Production engineering

Parts procurement

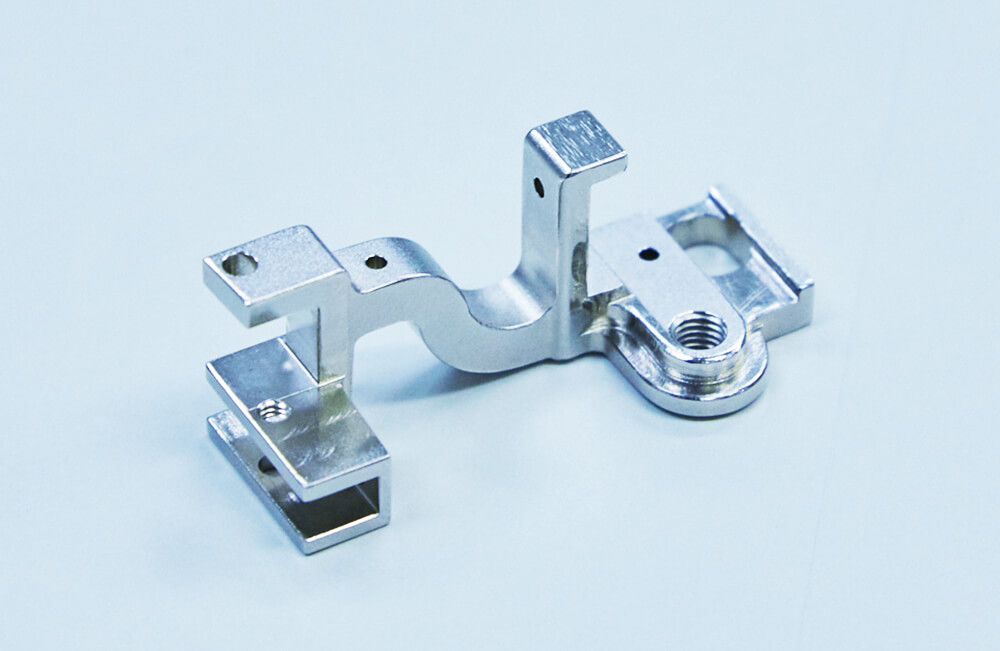

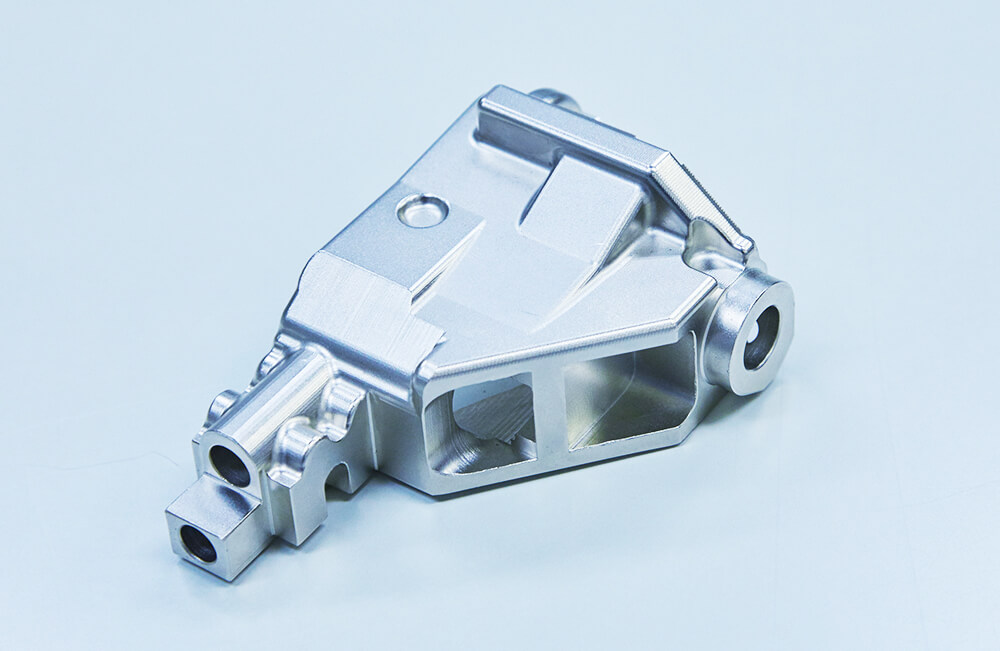

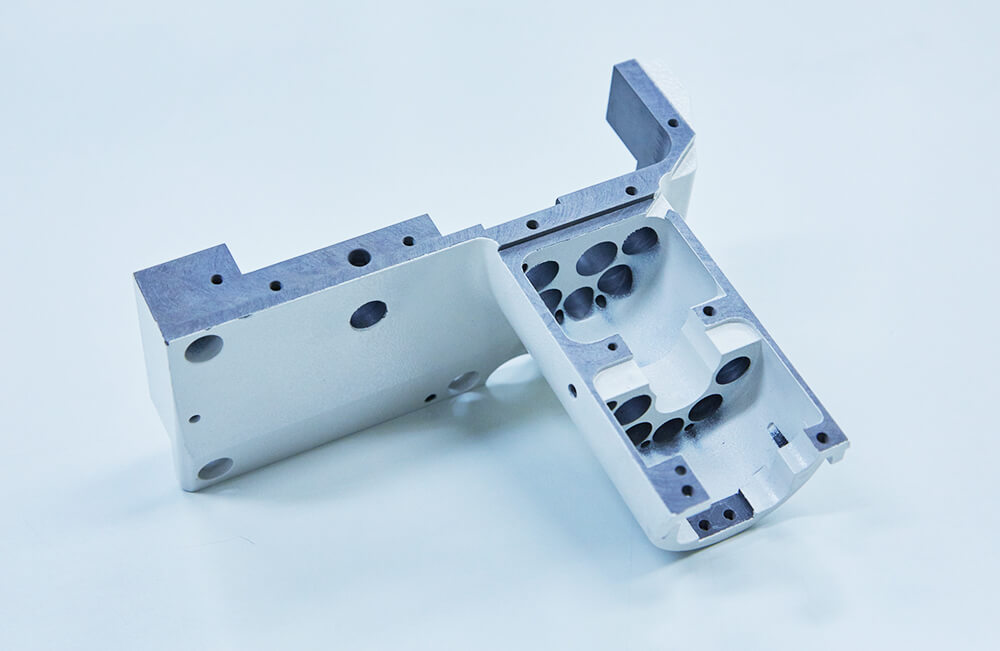

Parts processing

Advantages and features

We process parts in response to customer requests using the technologies, skills, and equipment developed in-house for the processing of sewing machine parts. We handle wide-ranging parts of all sizes, some for prototype application, others for mass-produced products.

Painting

Advantages and features

- We apply a wide array of paints and coatings using technologies and skills developed to suit the shapes and colors of JUKI’s various industrial sewing machines.

- We apply the specifications that the customer requests to our company’s original standards and maintain stable quality.

- Even when a customer worries that a specification or painting process will be difficult for JUKI to handle, we prepare the necessary painting environment and immediately make the necessary arrangements with our subcontractors (trading companies and paint makers).

- We produce products stably at high rates of output with a strict determination to detect and correct any form of unreasonableness, waste, and inconsistency in production.

Pretreatment

We apply optimum pretreatments for painting using exclusive chemicals that prevent the peeling of paint and boost the various tolerance effects. We also perform daily monitoring and adjustment to manage the concentrations of the chemicals we work with and periodically manage the ingredients supplied by chemical makers to maintain the stable paint quality.

Powder coating

Power coating can meet the requirements of “hammer tone painting” and “flat painting” for various powder coating applications. Various coating colors are also available.

Solvent coating

Solvent coating can meet the needs of “metallic painting,” “leather tone painting,” and “flat painting” centered on “bake coating” and “natural drying.” We can implement the whole working process from surface treatment to final coating. The coating colors are also wide ranging.

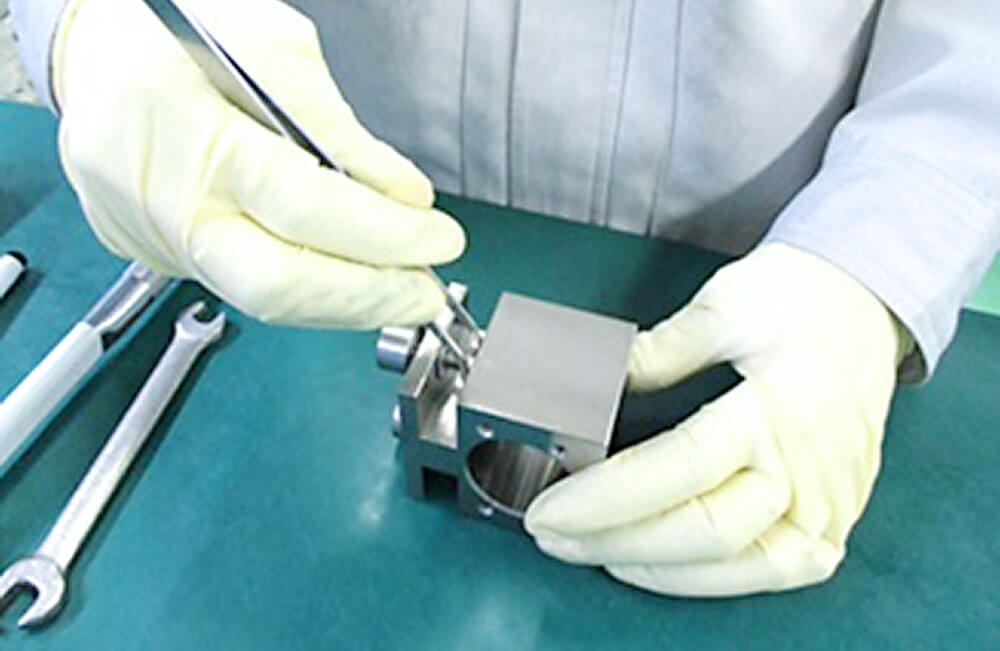

Assembly

Advantages and features

- We respond to a wide range of product assembly tasks using the technologies and skills developed through the assembly of industrial sewing machines.

- We apply the product assembly specifications that the customer requests to our company’s original standards and maintain stable quality.

- We verify the quality of every unit individually using the check sheets to maintain self-processing quality.

- We respond flexibly to customer requests for short delivery times by keeping our support system between departments ready at all times.

- We strive to make products with a strict determination to detect and correct any form of unreasonableness, waste, and inconsistency in production.

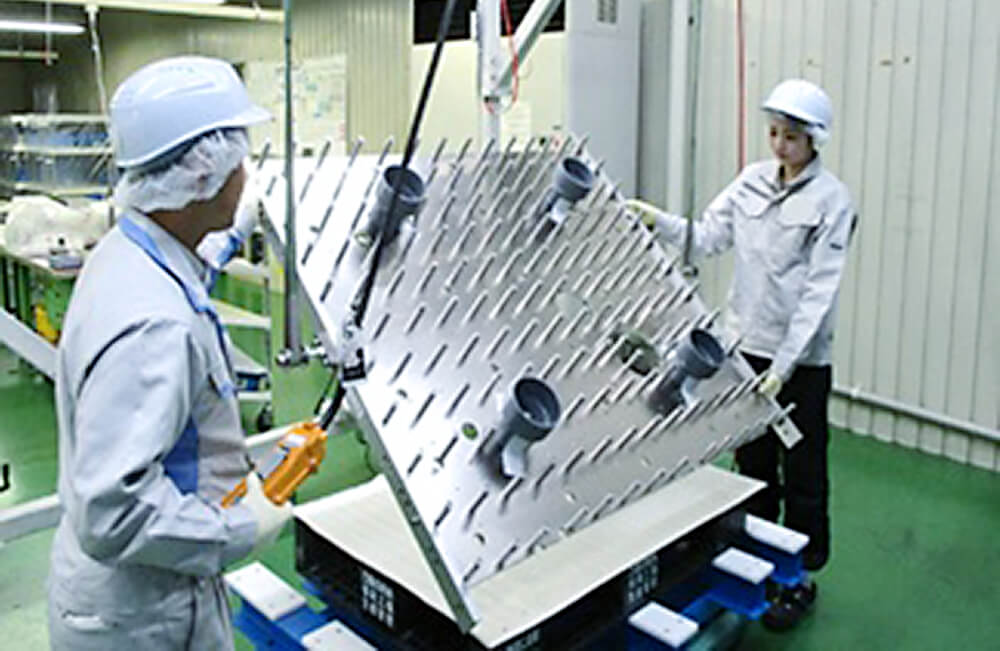

Work case: a large piece of equipment

We produce large products.

Work case: a small piece of equipment

We are thoroughly versed in detailed work.

Customer introduction

AIMECHATEC, Ltd.

https://www.ai-mech.com/wp_en/

Senior Engineer, Manufacturing Department, Manufacturing and Quality Division

We have the utmost confidence in JUKI’s ability as a manufacturing company dedicated to the pursuit of “the world’s best performance and quality.”

Our company develops and manufactures equipment to produce “flat-panel displays” used in wide-ranging products. Massive equipment weighing upwards of 60 tons, one of our product line-ups, processes parts with a micron-level of precision.

Our company was split off from Hitachi, Ltd. in July 2016 as the newly born AIMECHATEC, Ltd. The “AI” in our company name stands for Advanced and Innovative Technology. “Ai” in Japanese also means “love.” When written out in English in lower case, “ai,” these letters remind us of the love we have for both to our customers and products. We established a Process Development Center in July 2018 and continue to pursue further technical innovations and an expanded business domain.

Our outsourcing to the JUKI Ohtawara plant started with frame processing and has since expanded to the assembly of units. After training for about a month at our company, engineers from the JUKI Ohtawara plant built a jig and created a standard operation manual to improve the processes and ensure that everyone would perform high-quality assembly. I think that the certainty of JUKI’s manufacturing capacity, together with JUKI’s stoic determination to constantly find ways to improve no matter how well things are already working, enables JUKI to respond to the QCD we pursue.

We expect that the collective strength of JUKI’s production technology and quality assurance at the Ohtawara plant will help drive our next big leap to become a global company that pursues “Monodzukuri” as uncompromisingly as JUKI does.