Development department

This department develops new industrial sewing machine products and products and devices customized to customer requests while providing maintenance for the products it has already developed.

The department designs products and devices using a 3D-CAD system, analysis tools, and high-speed videos. The department is advancing the development of safe and high-quality products by using and improving differentiated independent technology and using and promoting open innovation.

The department is also developing new forms of environment-friendly “manufacturing” that customers appreciate. The department cooperates with the Manufacturing, Quality Assurance, Procurement, and Sales departments until products are completed.

Production engineering department

This department builds production lines and designs tools to perform highly efficient production at factories.

The department is aiming to operate as a smart factory that excels in the lean and highly efficient production of high-quality industrial sewing machines.

The department is aiming to develop, introduce, and apply highly efficient techniques for operation, automation, and labor-saving through the visualization of the working situations of both equipment and workers by expanding its links with group companies both at home and abroad centered on the Ohtawara plant as a mother factory.

QA department

This department maintains the quality of product as the “fort.” The department implements the PDCA cycle along a quality management system and realizes zero-complaint factories. The department also plays a role in promoting activities to create the base. The department is in charge of executing policy management, promoting QC circle activities that all employees participate in, eliminating waste in processes performed by humans, and maintaining and promoting an ISO9001-certified quality management system.

The job of quality assurance requires expert knowledge of quality control and deep knowledge about industrial sewing machines. The department works behind the scenes to offer refined knowledge to help factories eliminate the production of defective products.

Processing department

This department has two operations: one is to process industrial sewing machine bodies; the other is to process parts for the machines.

The department processes sewing machine bodies (arm and bead) with a machining center that stays running around the clock based on the software instructions for the models being processed. Eight kinds of robots are being installed in the line to handle heavy goods.

The department serves two functions: to process parts for industrial sewing machines and to produce parts especially requested by customers in the manufacturing industry (based on contracted development and manufacturing business).

The department processes small-lot parts, parts for prototypes, spare parts, and emergency response parts for industrial sewing machines with micron-level precision, all with an unstinting commitment to “make items in strict accordance with the drawings.” The department also performs heat treatments for parts (carburizing quenching and tempering, ion nitriding, and neutral salt-bath furnace immersion). The department is manned by a group of slightly uncompromising artisans who operate their machines with veteran skill and knowhow.

They also apply their artisanal skill to make jigs and tools for the factory.

Painting department

This department applies “powder coatings and solvent coatings “on industrial sewing machine bodies (head: arms and beds) and small parts. The department paints parts according to the specifications required by customers in the manufacturing industry (as a contracted development and manufacturing business). Many of the personnel in the department hold national qualifications for metal coating.

The department powder coats sewing machine bodies processed upstream on the line. The software-driven robot paints automatically to optimize workability and minimize dangers and adverse impacts on human bodies in the workplace. The software instructions depend on the models being painted. Painting processes for special sewing machines formerly managed by skilled workers are now fully performed by machine. The department prevents variations in the receptiveness of the sewing machines to paint by heating the frames before applying the undercoats and raises painting performance by maintaining stable coating films.

One process still handled by humans is the attachment of the “JUKI logo” to every machine one by one while most of operations in the department are being automated.

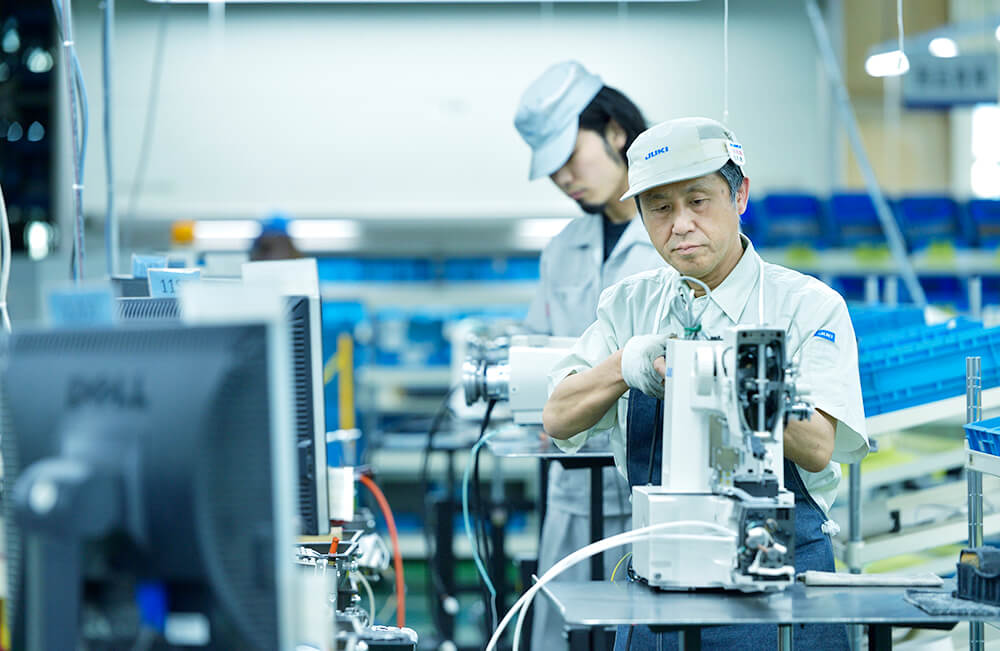

Assembly department

The largest number of workers in this factory work to finish the industrial sewing machines on the production line by mounting various parts, driving motors, and thread trimming units on the painted sewing machine bodies.

The department is trying to improve technologies and skills by educating and training its people to work with nine elemental technologies applied in machine assembly and skills needed for screw-tightening and matching work. The department is also working to improve its workplace based on the principle of SANTEI (fixed position, fixed quantity, and fixed article) in the 5S framework.

The department is evolving a more efficient production system with mix flow and takt systems every day with help from “digital cell production” system supported by the visualization of assembly procedures and necessary parts and tools on PC monitors

Inspection department

This department performs different types of inspections. The department inspects the parts that the Parts Center in the factory purchased, the sewing machine body, and the measuring instruments being used in the factory using the various devices.

The department has introduced a system to manage inspection records and information as electronic data based on JUKI’s mission-critical system (JMENU), a system the department started using in 2012. The department is also working on smart inspections.

Procurement department

This department purchases materials and parts needed to produce industrial sewing machines. The department purchases high-quality materials only when needed, only in the amount needed, and at appropriate prices, based on production plans formulated in cooperation with the Tama Head Office, a fellow procurer in JUKI family.