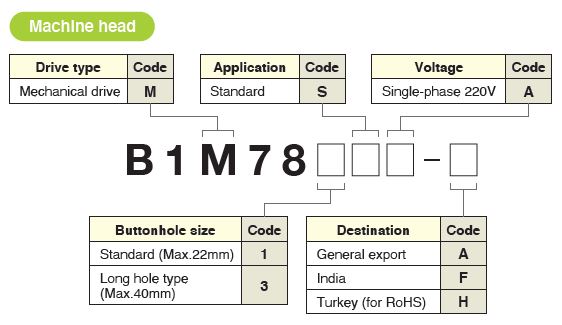

1-needle, Lockstitch Buttonholing Machine

The B-1M Series buttonhole machines produce consistent quality seams and are widely adaptable to many different kinds of materials and seam specifications.

Product overview

Product features

The control box is integrated into the head

The control box is integrated with the head of the sewing machine, making it easy to set up and use.

The B-1M Series adopt the direct drive system. As a result, Quietness of the sewing machine during sewing is ensured by the direct-drive motor.

The sewing machine starts up swiftly and promises increased stop accuracy, thereby demonstrating improved responsiveness.Comfortable working environment

The knife mechanism and stop-motion mechanism produce less noise when they actuate, thus contributing to a more comfortable working environment. Thanks to the simple design of the stop-motion mechanism and unique knife mechanism, the machine operates with low noise. The machine starts, decelerates and stops smoothly.

Basic performance

Lift of the work clamp

The work clamp foot height can be increased up to 12 mm, enabling the machine to make high-quality buttonholes in heavy-weight materials. The lifting of the work clamp is driven by a motor, which reduces operator work. The operation can be easily done with one pedal.

LED light

The LED light is located on the underside of the arm jaw. It is provided as standard for all models of the B-1M Series. It reduces operator fatigue and improves work efficiency.

In addition, this needle drop point can be easily visually observed. This permits easy positioning of buttonholes.Sewing settings can be easily changed

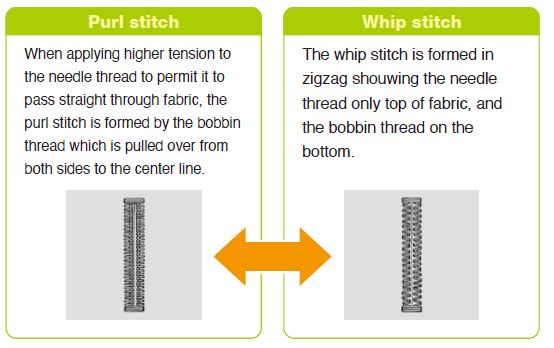

This machine is capable of forming two different types of stitches, namely whip stitch and purl stitch.

Standard operation panel

The sewing machine has been integrated with the operation panel and the control box for ease of use. The operation panel has a simple design that allows the user to adjust the origin position of the feed

cam and change the sewing speed.Changing the number of stitches

The gears are ibcluded in the standard accessories.

● Spur gears

By selecting the spur gears, your can control the number of stitches as shouwn in the table. Use a combination of gears which have the samealphabetical marks.

The numeral engraved on the gear installed in the rear position will represent the number of stitched provided by the then combination of spur gears.

Specification

| Model name | B-1M781S | B-1M783S |

|---|---|---|

| Application | Standard | |

| Max. sewing speed | 3,600sti/min* (Factory default: 3,300sti/min*) | |

| Needle bar stroke | 34.6mm | |

| Lift of the work clamp | 12mm | |

| Thickness of material that can be used | 4mm (with the work clamp lowered) | |

| Number of stitches | 83~225 (by gear-change method) | |

| Length of buttonholes | 22mm | 40mm |

| Needle | DP×5 #11~#14 | |

| Hook | DP type, automatic-lubricating full-rotary hook | |

| Lubrication | Automatic | |

| Lubricating oil | Sewing machine oil #10 (ISO VG10) | |

| Power supply / Power requirement | Single-phase 220V | |

| Power consumption | 366VA | |

| Weight | Machine head (include motor) 50kg | |

*sti/min is the abbreviation for “stitches per minute”