Computer-controlled, High-speed, Lockstitch, Button Sewing Machine

The direct drive system has been adopted.

The control box is integrated with the machine head.

Active tension is standard equipment.

Product features

Active tension (electronic thread tension control mechanism)

The active tension has been introduced to the needle thread tension controller. With the active tension, pinpoint changes in the needle thread tension during sewing are enabled.

The needle thread tension, therefore, can be set in conjunction with the material thickness and can be corrected according to the direction of sewing on a stitch-by-stitch basis through the operation panel. Since the needle thread tension is reproducible, supporting a broader range of sewing conditions.The control box is integrated into the head

The control box is integrated with the head of the sewing machine, making it easy to set up and use. All of the K-1E Series adopt the direct drive system. As a result,

the sewing machine starts up swiftly and promises increased stop accuracy, thereby demonstrating improved thereby demonstrating improved responsiveness.

Basic performance

Operation panel

Functional settings, such as pattern numbers and needle thread tensions can be established through the operation panel with ease. Distance between holes in a button can be easily changed by means of pattern enlargement/reduction feature.

●USB port

The K-1E series is equipped as standard with a USB port that can be used to charge smartphones, etc.Oil stains are eliminated

Thanks to our advanced dry-head technology, the frame (needle bar and thread take-up) no longer requires lubrication.

This prevents the material from being stained with lubricating oil.

Addressing oil stains incurs various costs, including personnel expenses, cleaning equipment, detergents, and the space required for setting up these facilities.

LED light

The LED light is located on the underside of the arm jaw. It reduces operator fatigue and improves work efficiency.

It is provided as standard for all models of the K-1E Series.

Specification

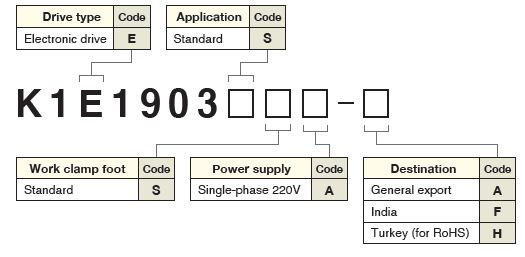

| Model name | K-1E-1903SS |

|---|---|

| Application | Medium weight material |

| Lubrication | Semi-dry head (Hook: minute-quantity lubrication) |

| Max. sewing speed | 2,700sti/min* (Factory default: 2,000sti/min*) |

| Sewing area | Φ10~Φ24 |

| Stitch length | 0.1~10mm (0.1mm step) |

| Needle bar stroke | 41.2mm |

| Lift of the work clamp foot | Standard 13mm (17mm when the reverse-rotation needle-up function) |

| Auto-lifter | Provided as standard (stepping motor type) |

| Needle thread tension | Active tension (electronic thread tension control system) |

| Needle (at the time of delivery) | DP × 17 (#14) |

| Hook | Standard shuttle hook |

| Number of stitches that can be stored in memory | Max.13,000 stitchs |

| Number of standard patterns | 100 patterns |

| Number of data that can be input | 200 patterns |

| Enlarging / Reducing facility | 20~200% (1% step), Pattern enlargement / reduction can be done by increasing / decreasing the stitch length |

| Memory medium | Internal-organs memory |

| Bobbin thread counter | Provided as standard (up / down method) |

| Lubricating oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) |

| Sewing machine motor | Compact AC servomotor (direct-drive system) |

| Power supply / Power requirement | Single-phase 220V |

| Power consumption | 610VA |

| Weight | Machine head 48kg |

*sti/min is the abbreviation for “stitches per minute”