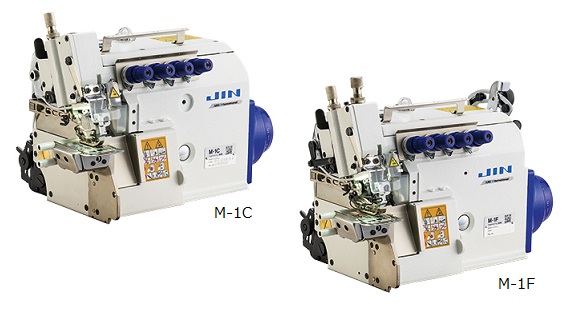

Direct-drive, High-speed, Cylinder-bed, Overlock Machine

The direct drive system has been adopted.

The operation panel is integrated with the control box.

Product features

New and powerful machine for sewing tubular materials!

The M-1C/M-1F Series sewing machine, provided with a small-in-diameter cylinder bed, is capable of runstitching or blind-hemming tubular materials, such as sleeve cuffs, with ease. The operator can carry out sewing of the tubular material while turning it downward. This promises improved workability and contributes to dramatically increased productivity.

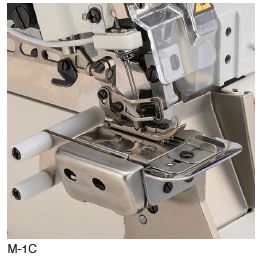

Small-in-diameter cylinder bed

The cylinder is bestsuited to the runstitching and blind hemming of tubular materials.

The machine comes with the top feed dog that moves along an ideal locus (M-1F)

The feed dog securely catches the material and allows the multi-layer portion of a material to be fed under it with consistency. In addition it helps finish uniform seams while preventing the presser foot from jumping and smoothly feeds the material without fail. Compact-shape of the cylinder effectively prevents the material from being fed unevenly and from twisting in various kinds of sewing of tubular materials eg., joining sleeve cuffs of which diameter is small and blind hemming long materials.

Basic performance

The operation panel is integrated with the control box

The sewing machine has been integrated with the operation panel and the control box for ease of use. The operation panel has a simple design such as switching the vertical position of the needle and setting the maximum sewing speed.

LED hand light

The LED hand light is standard equipment for all M-1 series. (ON/OFF setting possible)

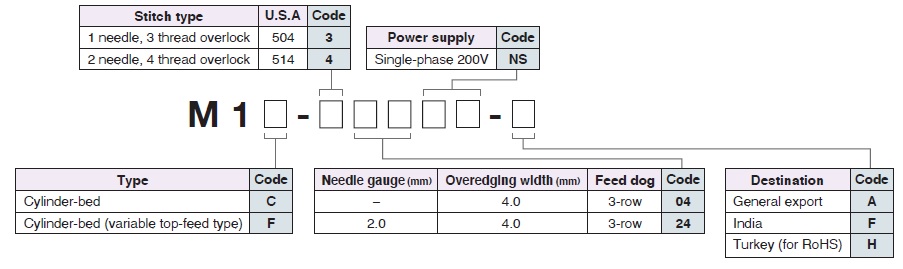

Specification

| Model name | M1C-304NS | M1C-424NS | M1F-304NS | M1F-424NS |

|---|---|---|---|---|

| Stitch type | 1-needle overlock |

2-needle overlock |

1-needle overlock |

2-needle overlock |

| Max. sewing speed | 6,000sti/min* | 5,500sti/min* | ||

| Stitch length | 3.8mm | |||

| Needle gauge (mm) | - | 2.0 | - | 2.0 |

| Overedging width (mm) | 4.0 | |||

| Needle bar stroke | 23.0mm | |||

| Needle | DC×27 #11 | |||

| Max. lift of the presser foot | 5.0 mm | |||

| Lubrication | Automatiac | |||

| Lubricating oil | JUKI Machine Oil 18 (equivalent to ISO VG18) | |||

| Cartridge oil filter | Provided as standard | |||

| Power requirement | Single-phase 220V | |||

| Power consumption | 608VA | 538VA | ||

*sti/min is the abbreviation for “stitches per minute”