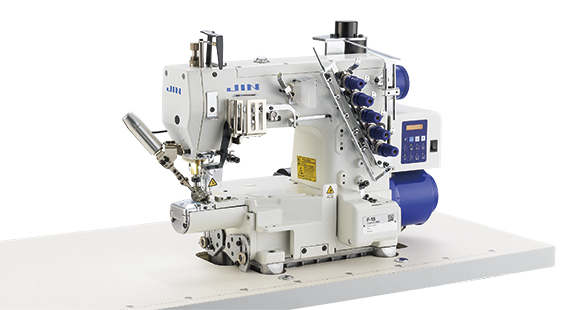

High-speed, Small Cylinder-bed, Top & Bottom Coverstitch Machine

The sewing machine is applicable to the sewing of sleeve cuffs, necklines and children’s wear.

The direct drive system has been adopted.

Operation panel and control box are integrated with the machine head.(with thread trimming device)

Product features

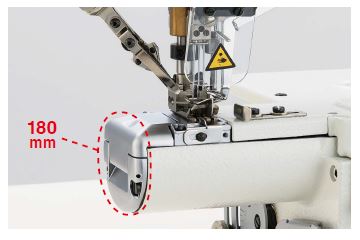

Outer circumference of the cylinder section is 180 mm!!

The outer circumference of the cylinder section has been reduced to 180 mm.

This allows the sewing machine to easily sew conventionally hard-to-sew small-in-diameter tubular parts such as the sleeve cuffs of sportswear and ladies’ cut-and-sewn wear and the necklines of children’s wear.Stitch length adjustment mechanism and differential-feed ratio adjustment mechanism

1 The stitch pitch (stitch length) can be easily adjusted by adjustment the stitch lever.

2 The differential-feed ratio adjustment mechanism can be made possible to adjust the differential feed amount to a best-suited value for the material to be used. In addition,the differential feed ratio remains the same even when the stitch length is changed.

Basic performance

The operation panel is integrated with the control box

The sewing machine has been integrated with the operation panel and the control box for ease of use. The operation panel has a simple design such as switching the vertical position of the needle and setting the maximum sewing speed. The operation panel of the type with thread cutter has additional keys for presser-foot and trimming functions, etc.

LED light

The LED light is standard equipment for all F-1S series. (ON/OFF setting possible).

Universal type (basic type)

The machine can be used for the hemming process of the sleeves and bottoms of T-shirts and for the covering process for sportswear and knitwear. It is not a specific-purpose model, but a basic one which can be used for a broader range of processes independently.

Specification

| Model name | F-1S-U |

|---|---|

| Stitch type | 3-needle top and bottom covering stitch |

| Max. sewing speed | 5,000 sti/min* |

| Stitch pitch adjustment | By lever |

| Differential feed adjustment | By lever |

| Needle bar stroke converting function | 31.0mm |

| Lift of the presser foot | 5mm (with top and bottom covering stitch), 6mm (with bottom covering stitch) |

| Needle | UY×128GAS #11 (#11~#14) |

| Lubrication | Automatic |

| Lubricating oil | JUKI Machine Oil 18 (equivalent to ISO VG18) |

| Silicon oil tank for needle tip and needle thread | Provided as standard |

| Cartridge oil filter | Provided as standard |

| Power requirement | Single-phase 220V/Single-phase 110V |

| Power consumption | 781VA |

*sti/min is the abbreviation for “stitches per minute”