Case Studies

Quantification of sensory testing

Before

Customer concerns

- Variation is caused by the experienced value of the inspector, fatigue condition, etc.

- Inspection judgement errors may occur due to blurring of inspection criteria.

- Be costly to adopt and educate inspectors

- Difficult to pass on inspection technology

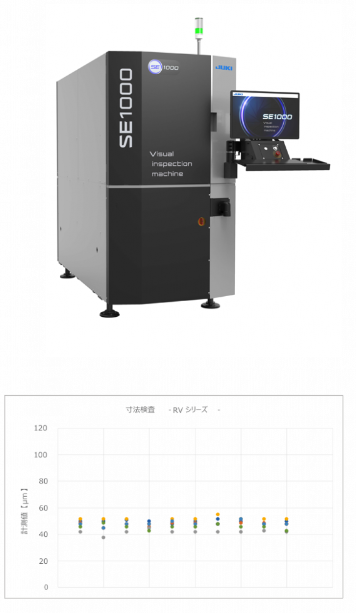

After

Customer feedback after introduction

- Evaluation criteria for inspection were clarified, and inspection judgement errors were eliminated.

- There was no knack for human judgement, and overlooking of the inspection was eliminated.

- Inspection standard irregularity due to inspection time has disappeared

- There was no difference by the experienced value, and the inspection quality became constant.

- Quality was improved by quantifying inspection contents and items.

- Labor saving was realized.

- JUKI inspection algorithms and AI are utilized to enable continuous and accurate inspection.

To the list of Inspection and Measurement cases