Parts management automation solution

Would you like to worry about this?

- Some parts require humidity control

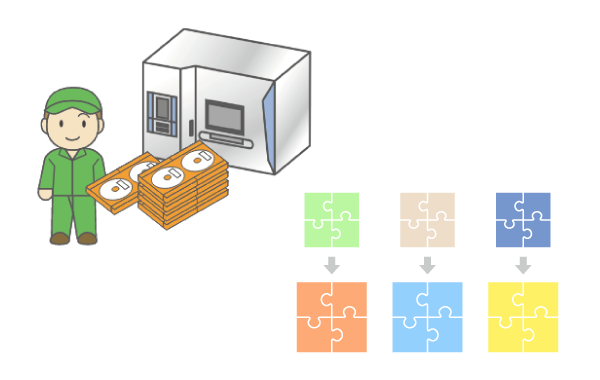

- I want to manage loose parts and cut parts

- The first-in first-out rule is not thorough.

- Parts shipping errors have resulted in double troubles

- More parts types and more complicated warehouse management

- I don’t know where the parts I’m looking for

- Have ordered excess parts

- I want to reduce the burden on workers

- It is troublesome if the person in charge of the parts business takes a rest

- The parts management is not put into a database.

- I want to shorten the inventory timing proposal

- I want to shorten the lead time and use the funding

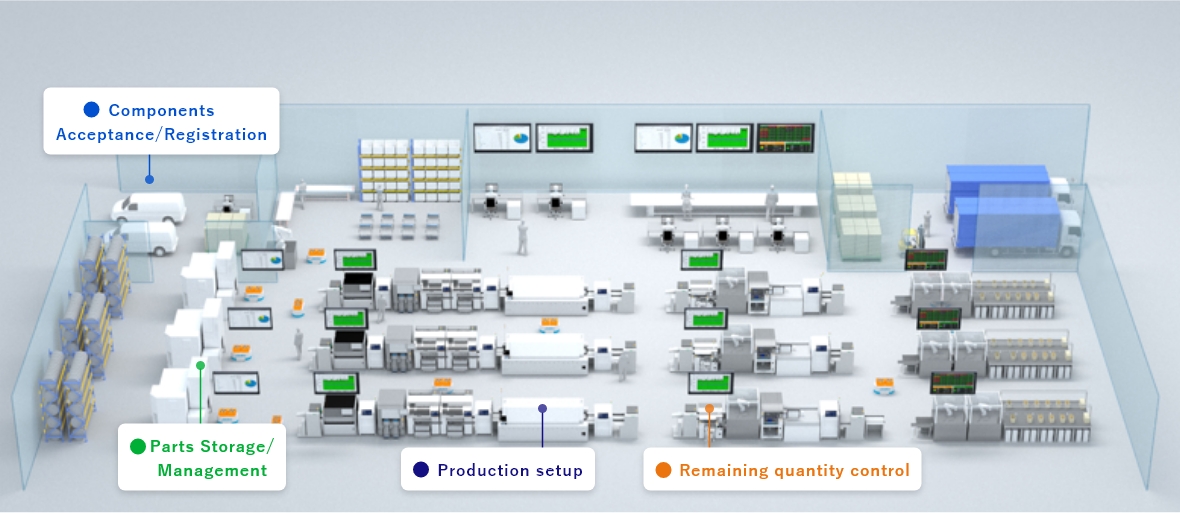

JUKI’s parts management automation solution solves various problems in parts management, such as space saving and system linkage.

It can be used not only to manage electronic components but also to manage components in the assembly process.

Ideal for customers

- Studying efficiency of picking work due to labor shortage

- Concept of improving space efficiency

- Those who want to confirm inventory in real time

- How to reduce inventory man-hours

- Concept of data coordination for extraction instructions

- Improvement of productivity by announcing that parts have run out

Estimated usage scene

- Management of important automobile parts

- Control of jewelry and other valuables

- Drug control at pharmacies

- Inventory management at retail stores

- Management of maintenance parts on plant lines

Main Features

Five points

- Compatible with various types of supply

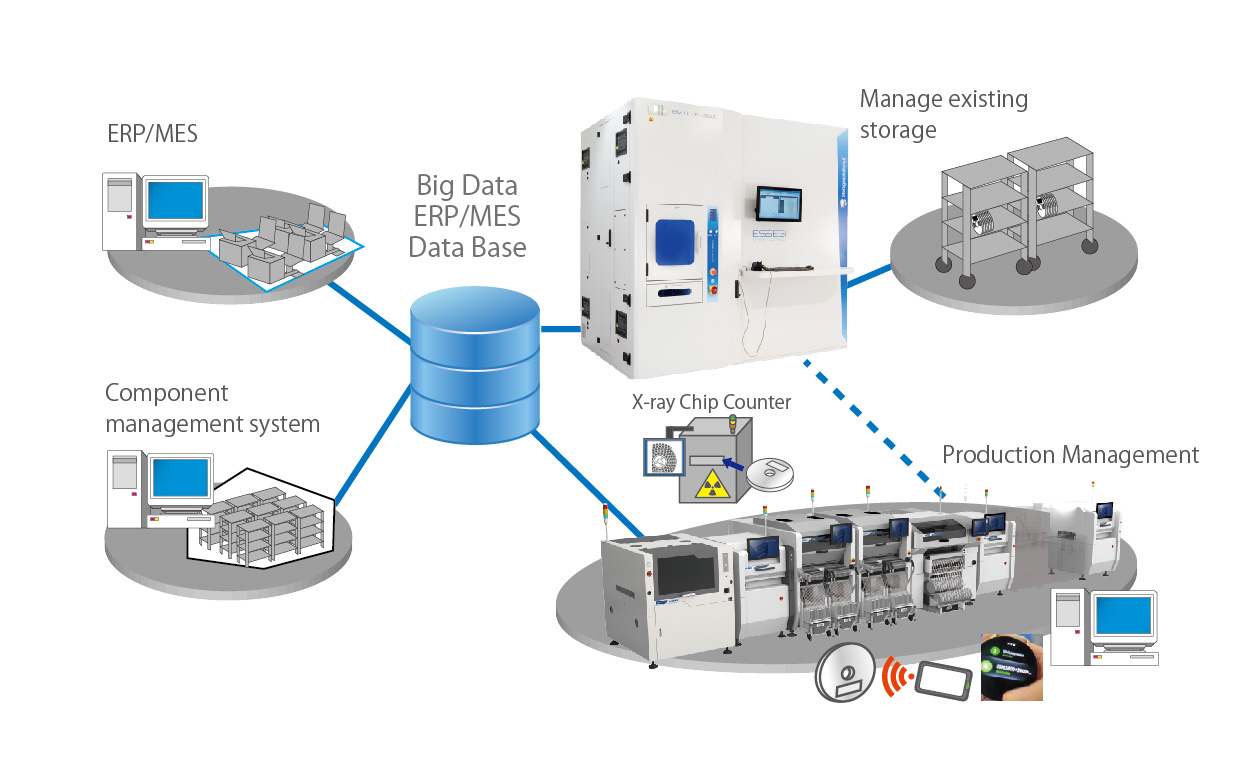

- Improved efficiency through system coordination

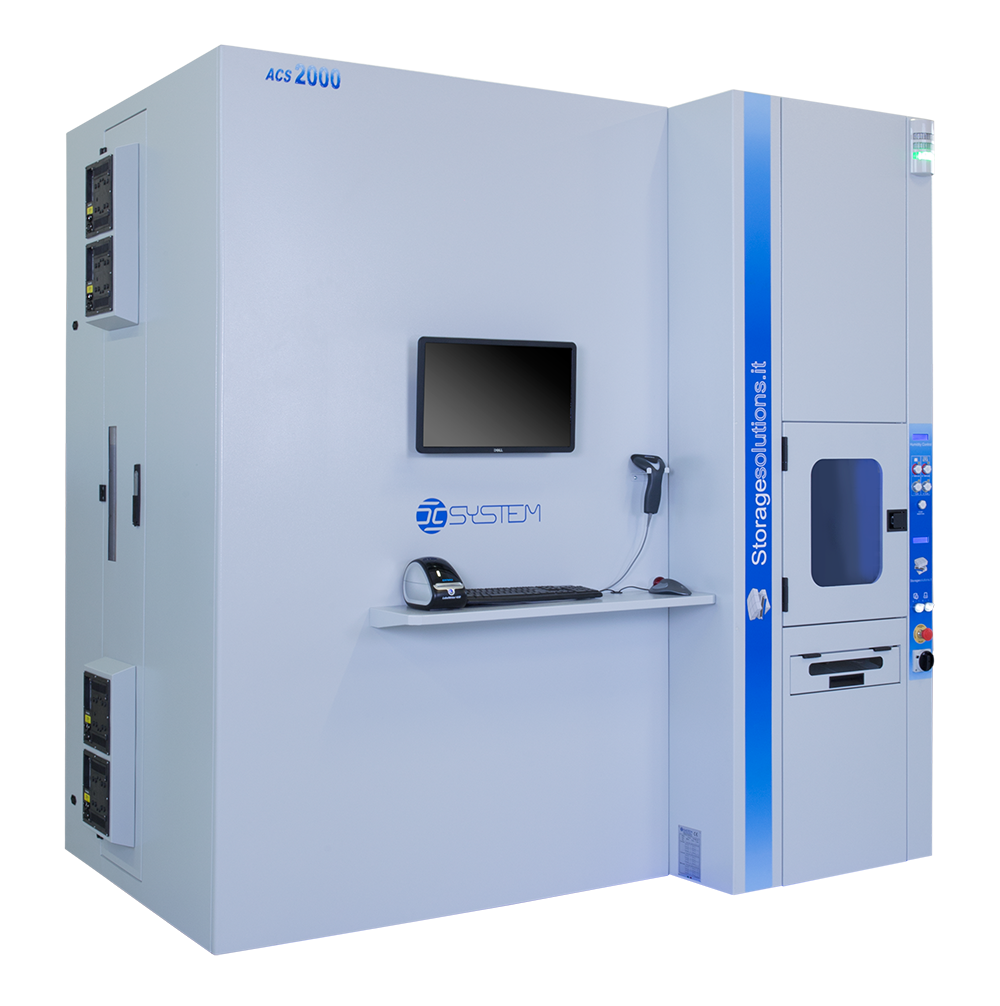

- Space savings

- Humidity control

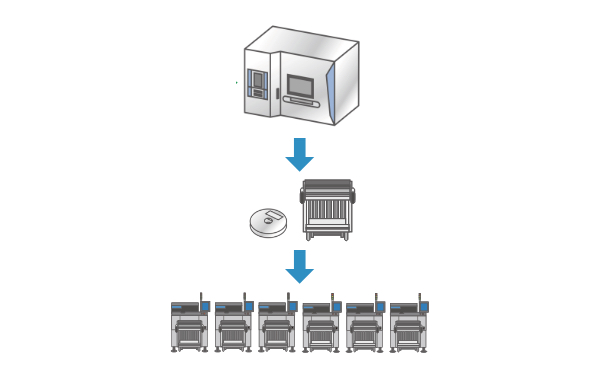

- Automatic loading/unloading is possible

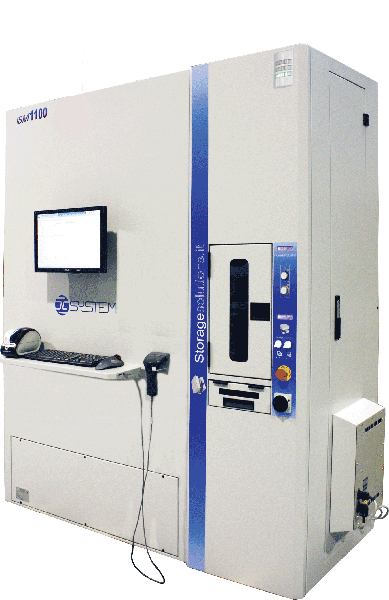

Overview

- It is equipped with ISM exclusive software. It can collectively manage inventory status such as inventory control and inventory control.

- No major system changes are required.

- Data files (CSV, etc.) and API can be linked with various systems.

- It is easy to construct a system tailored to the customer’s operation method.

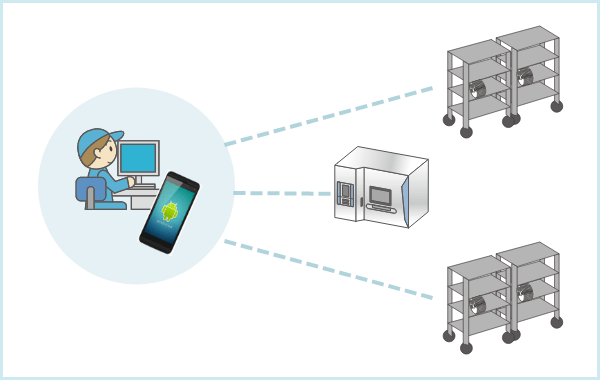

- You can use ISM more easily with JUKI・ISM Connection (software).

- It can be extended to automated AGV transport. Smart factories are realized.

Examples of introduction

Automation case studies:

Parts management

Improvement of work efficiency (real-time inventory control)

Automation case studies:

Parts management

Improvement of work efficiency (systematization of existing shelves)

Automation case studies:

Parts management