Inspection and measurement automation solution

Would you like to worry about this?

- Want to automate visual inspection

- I want to reduce inspection time and realize exhaustive inspection

- I want to quantify visual and sensory inspections to eliminate variations in inspection quality

- Incorporating Inspection and Measurement Processes in-line

- Reducing the number of personnel inspection and man-hours required for control

- I want to leave the traceability of the inspection

JUKI’s inspection and measurement automation solution solves that problem.

Ideal for customers

- How do I want to automate visual inspection?

- How to reduce inspection time

- Users who want to make inspection and measurement processes in-line

- Those who want to perform exhaustive inspection

- How to eliminate variations in quality

- How do I quantify inspection quality?

- Persons who want to carry out dimension measurement

- Persons who want to traceability of inspection

- Those who want to realize skillless and high-quality manufacturing

- How to automate the entire inspection process

- People who suffer from labor shortage in the inspection process

Estimated usage scene

- Full number of precision inspections of the forming state of precision parts are possible.

- Realizes high-precision inspection of medical instruments and other items essential to advanced medical technology.

- Ideal for all precision inspections of critical parts (such as brakes, air bags, parts required by engines, and gears) that require high quality.

Main Features

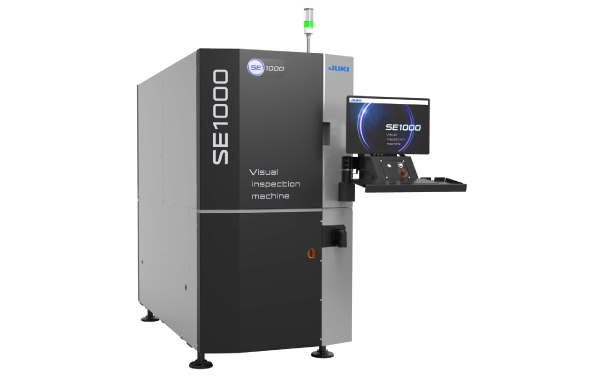

Highly versatile machine

- Inspection programs for a wide variety of parts and inspection details

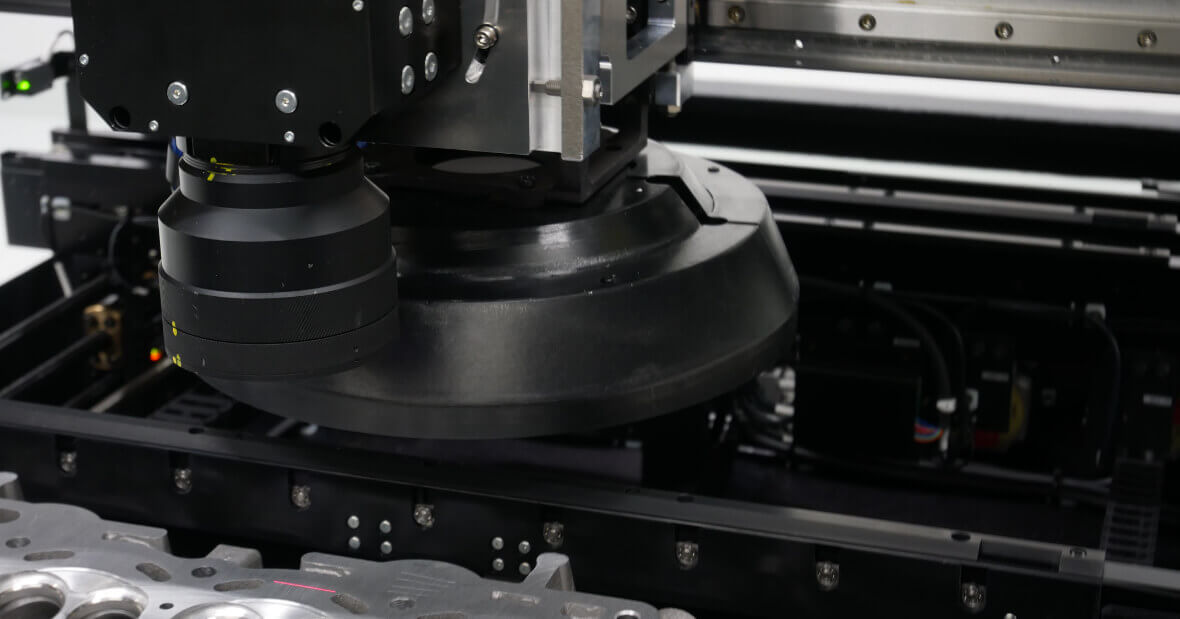

High accuracy inspection

- Optical camera unit for clear image acquisition and high-rigidity casting frame

- Adopts high-rigidity casting frame that integrates JUKI’s proprietary casting processing techniques

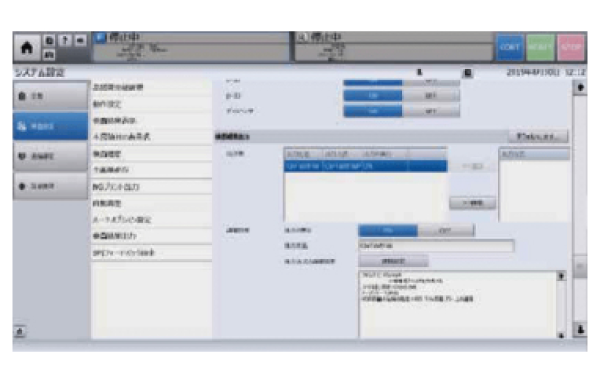

All-in-one inspection machine with all hardware and software

- Appearance inspection machines that incorporate all of the hardware of cameras, lights, PCs, and the software that controls them

- Support for customers through consistent response before and after introduction

Examples of introduction

Automation case studies:

Inspection and Measurement

Increased productivity

Realization of exhaustive testing

Automation case studies:

Inspection and Measurement

Increased productivity