Improvement of work efficiency (efficiency of warehousing work)

Before

Customer concerns

- We want to reduce inventory time.

- We want to shorten the storage time.

- We want to thoroughly carry out first-in and first-out of parts.

- Have workers do a variety of work.

- Work man-hours differ depending on new people and veterans (difference in skills)

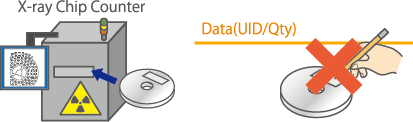

- In the remaining quantity control process, workers use a reel counter to fill in it by hand, and it takes a lot of time.

After

Customer feedback after introduction

- By the system cooperation with the X-ray counter, the inventory time was able to be reduced by about 90%.

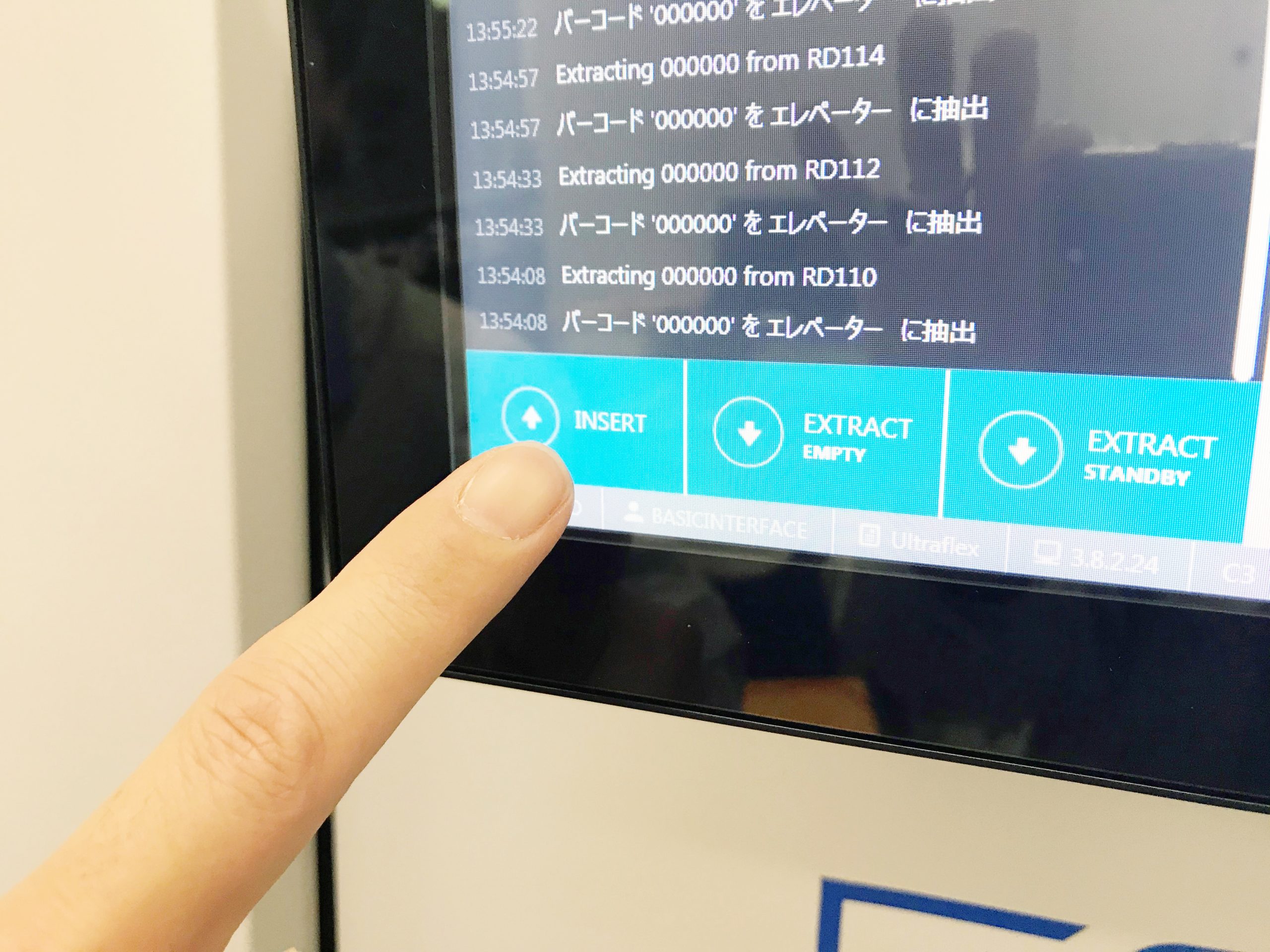

- Since ISM automatically go in and out at one time, we were able to reduce the number of hours involved in going in and out.

- Since the first-in and first-out of the components can be done at ISM, the checking operation of the worker was able to be reduced.

- Since the warehousing time could be reduced, the worker became able to carry out another work.

- A share of work was achieved.

- As a veteran member with the ease of entry and exit work by a new worker We was able to go to other work.

- The use of Incoming Material Station has reduced acceptance errors.

Image of remaining number of X-ray counter

Introduction example

| Before | After |

|---|---|

| 2171 min/month | Reduced to 1250 minutes per month |

58% reduction

NEW PRODUCT

Parts Acceptance Register Incoming Material Station

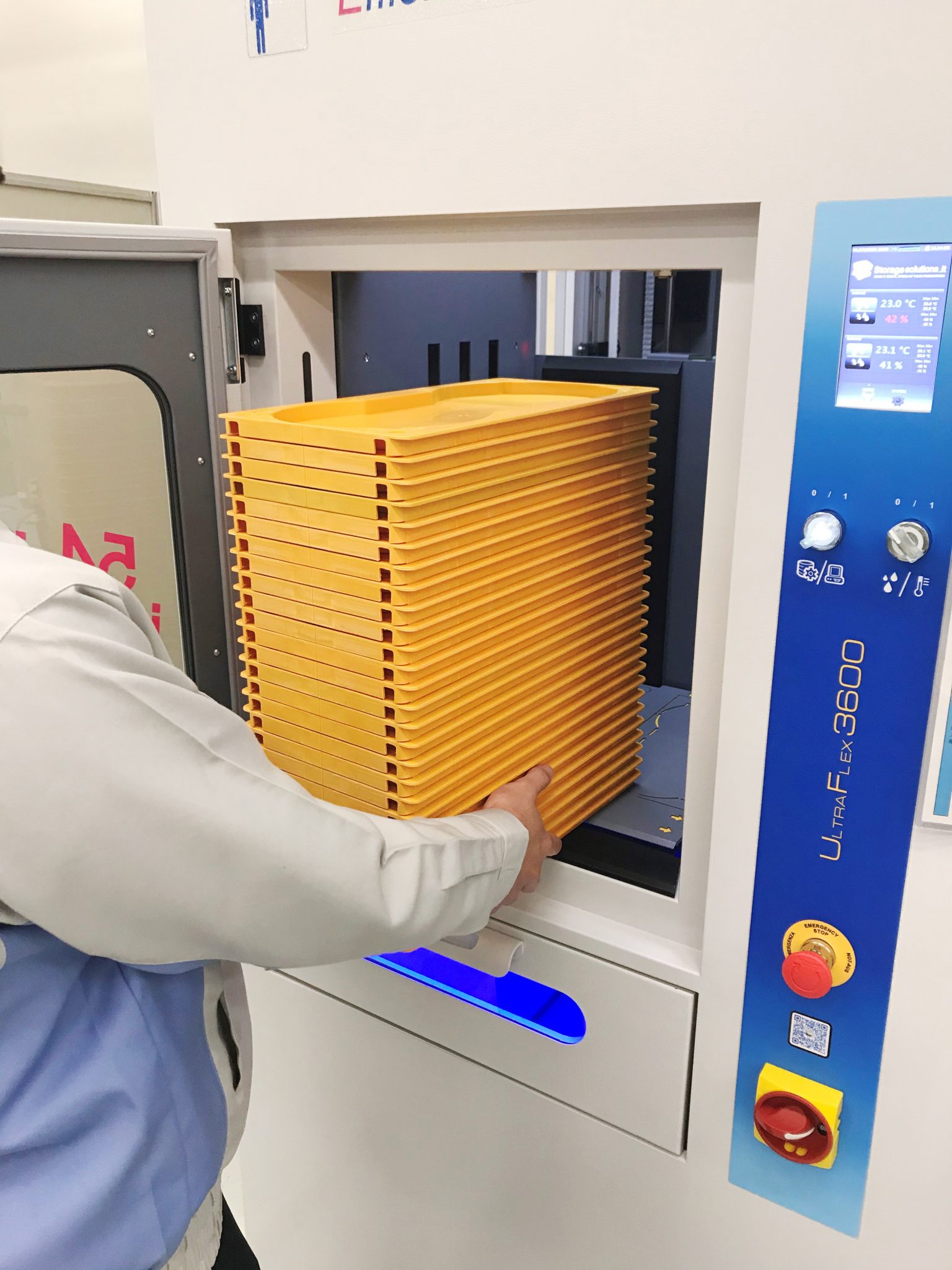

Incoming Material Station is efficient for receiving reel-related materials and reduces work errors.

It also improves data-entry and traceability while generating new unique ID during storage.

It also improves data-entry and traceability while generating new unique ID during storage.

Use in parts management: Realization of manpower saving by automatic picking

Before

Delivery by one reel while checking the number

After

Automatic picking by robot

No operator required during storage and retrieval

- Eliminate part picking errors

- Parts can be shipped first-in and first-out.

Use in assembly processes

The automated warehousing ISM series can also be used in the post-assembly process.

Parts can be safely managed not only in bulk but also in packages if they are sized to fit in a case.

The case height can be extended up to 88 mm.

To parts management case list