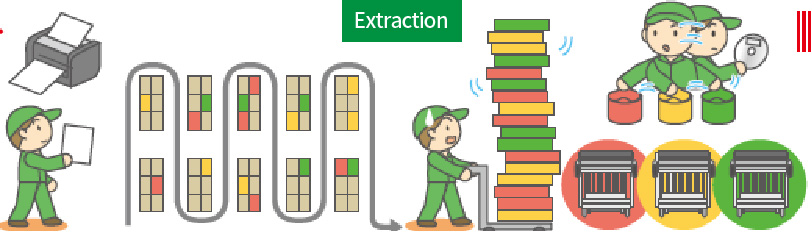

Automatic transport

Before

Customer concerns

- Since the warehouse is separated, the burden of the worker is large.

- Have workers do a variety of work.

- Manual parts handling is required.

After

Customer feedback after introduction

- Automatic transfer in AGV was able to be realized.

- Since the working time was able to be reduced, the worker became able to carry out another work.

Introduction example

Number of steps counted in a worker’s picking operation

| Before | After |

|---|---|

| 1,527,040 Walk/month | 572,640 /month |

60% reduction

Introduction of related products

Automated transfer ISM-AGV linkage

ISM and AGV are systematically linked to realize automation of part transfer from ISM and from ISM