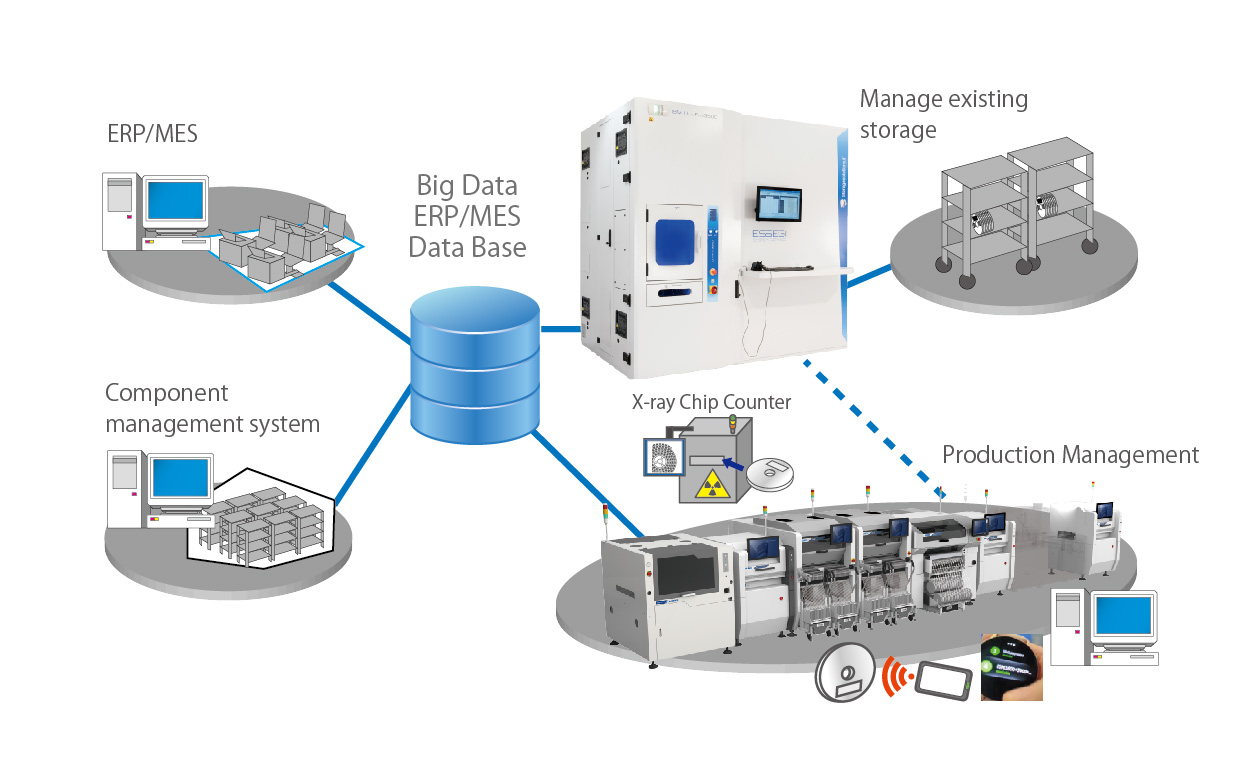

System linkage

Before

Customer concerns

- The parts management is not put into a database.

- We want to bring out the necessary number of parts in the production line considering them as well

- You want to use the currently used shelf as well.

- We want to operate it in cooperation with other systems such as production control systems

- Manual parts transportation work

- There are many chocolate stops due to shortage of parts during production, and the operation rate is poor.

- We want to check the production status and perform remote control at a place away from the production site

After

Customer feedback after introduction

- By analyzing it with a ISM, it was possible to reduce unnecessary delivery components.

- Real-time delivery is possible according to the number of parts required for on-site production

- System coordination enables the use of existing shelves

- Since it was possible to cooperate with various facilities and systems, and a large system change was also not necessary, it was able to smoothly introduce it.

- Automated transfer by AGV was realized.

- Automatic delivery of parts shortage warning has greatly reduced the stopping time.

- Multiple operations became possible by workers

- Remote operation was possible from a smartphone or smartwatch.

Introduction of related products

Smart Device Linkage System Smart Phone and Watch Linkage System

Remote control from smart devices possible