Case Studies

Improvement of work efficiency (systematization of existing shelves)

Before

Customer concerns

- Take time to pick

- The picking time varies depending on the level of the operator.

- Cause picking errors

- Want workers to perform various tasks

- Work man-hours differ depending on new people and veterans (difference in skills)

- Sudden stock shortage occurred

- It takes a long time to manage inventory.

After

Customer feedback after introduction

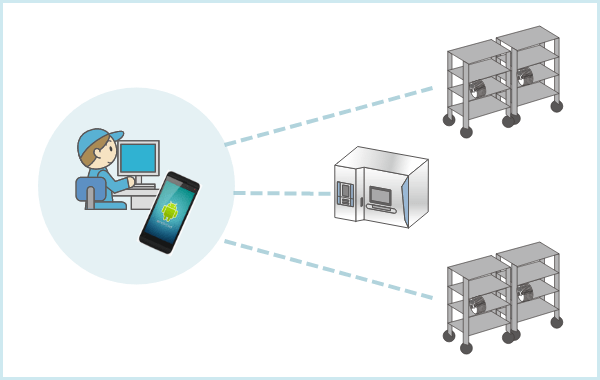

- Accurate inventory of parts shelves can be grasped in real time

- Reduction of the man-hour for picking work was achieved.

- Realization of skillless workers

- Multiple operations became possible by workers

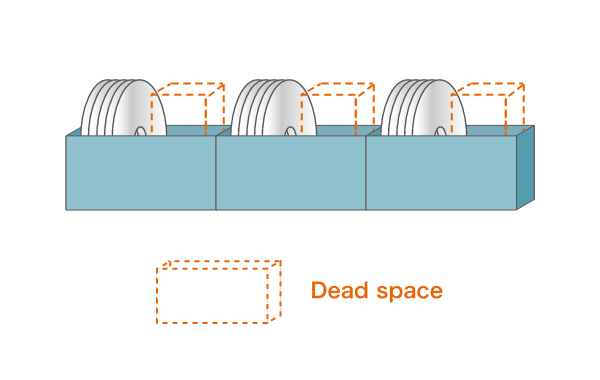

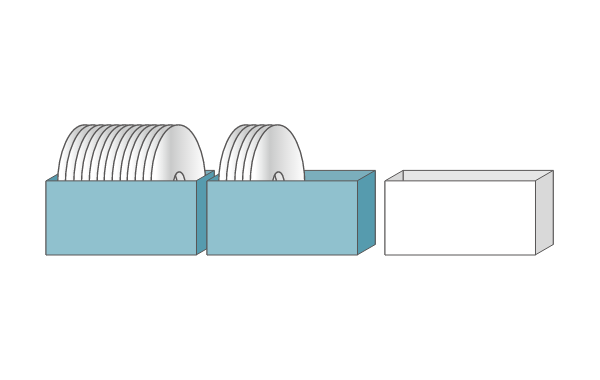

- Space saving was achieved by eliminating dead space.

To the list of Parts management cases