Case Studies

Improvement of delivery efficiency (combination parts management)

Before

Customer concerns

- It takes time to pick.

- A picking error occurs.

- Work man-hours differ according to new people and veterans (difference in skills).

- Skills are required to collect combination parts.

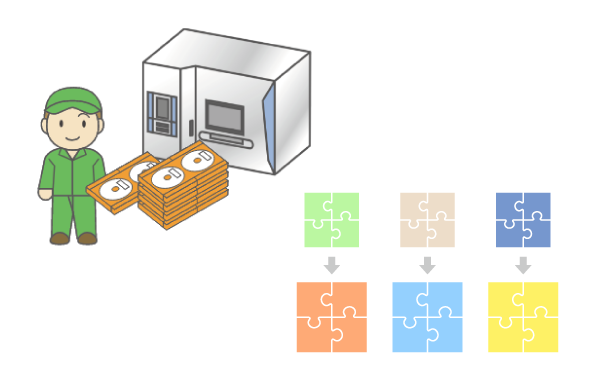

After

Customer feedback after introduction

- Reducing the workload of workers without skills

- Multiple operations became possible by workers

- Eradication of human error

- Drastic reduction in delivery time

Use in assembly processes

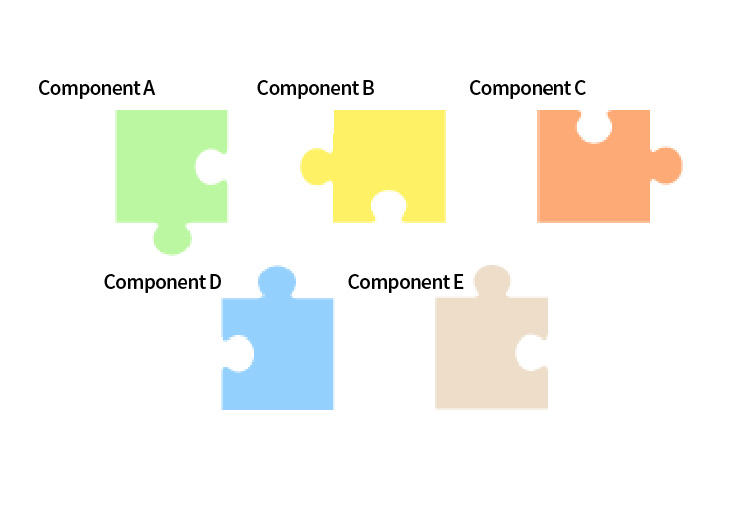

Inventory Analysis & Combined Inventory Delivery

- Combined delivery of paired parts is possible

- Determine the combination according to the delivery instruction.

- ✔ Delivery BOM datum on production planning × Production quantity Required part quantity Delivery

- ✔ No mispicking

- ✔ Can be shipped at first-in and first-out

To the list of Parts management cases