Semi-dry-head, Small-cylinder-bed, Top and Bottom Coverstitch Machine

The sewing machine is applicable to the sewing of sleeve cuffs, necklines and children's wear.

Small-cylinder-bed, Top and Bottom Coverstitch Machine

Semi-dry-head, small-cylinder-bed, top and bottom coverstitch machine has been added to JUKI's product lineup. The small cylinder-bed and semi-dry head features have been achieved while placing priority on ease of use. The sewing machine supports comfortable "sewing" work.

PEGASUS : W169P series

Product features

A world-first feature

DRY-HEAD TECHNOLOGY- The frame no longer requires oiling.

Unlike the conventional models, the oiling mechanism inside the frame has been eliminated. As a result, oil does not leak from the needle bar, presser bar or spreader shaft. - Dry-head technology has materialized a frame which does not need oiling.

The needle bar mechanism and spreader mechanism have been applied with a special surface treatment. JUKI's unique special grease is used for lubrication. Grease-filled bearings have been adopted for the crank rod. These allow the machine's frame mechanism to demonstrate outstanding durability without being oiled. - Environmental consciousness

Since oil stains on sewing products are reduced, the quantity of the use of stain remover generally used in sewing plants can be reduced.

*Dichlorofluoroethane (HCFC-141), which is generally used in oil stain cleaning fluid, is included in those chemicals which need to be reduced, as it is a substances that can harm the ozone layer.

- The frame no longer requires oiling.

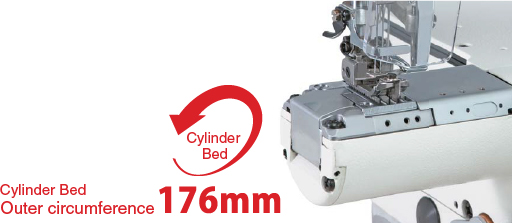

Outer circumference of the cylinder section is 176 mm!! *

The outer circumference of the cylinder section has been reduced to 176 mm. This al lows the sewing machine to easi ly sew convent ional ly hard-to-sew small-in-diameter tubular parts such as the sleeve cuffs of sportswear and ladies' cut-and-sewn wear and the necklines of children's wear.

* Outer circumference measured at the needle entry section of the small cylinder bed type sewing machine

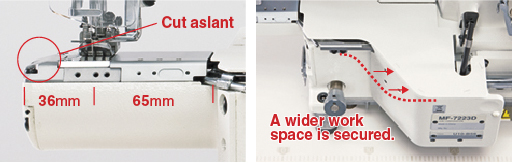

The sewing machine has been designed to achieve ease of use, placing the highest priority on easy handling and placement of the material on the sewing machine

- The distance from the needle entry to the top end of the cylinder bed has been reduced to 36 mm, thereby facilitating the sewing and handling of the sharp curves of the armholes of children's wear.

- The cylinder length from its top end to the root has been increased to 65 mm, thereby ensuring easier sewing of the long sleeve cuffs of sweat shirts.

- Since the top end of the cylinder bed has been cut aslant, placement/removal of the material on/from the sewing machine is carried out with ease.

- The front cover has been tilted and shifted to the right. As a result, the distance from the machine arm to the needle has been widened to increase ease of work.

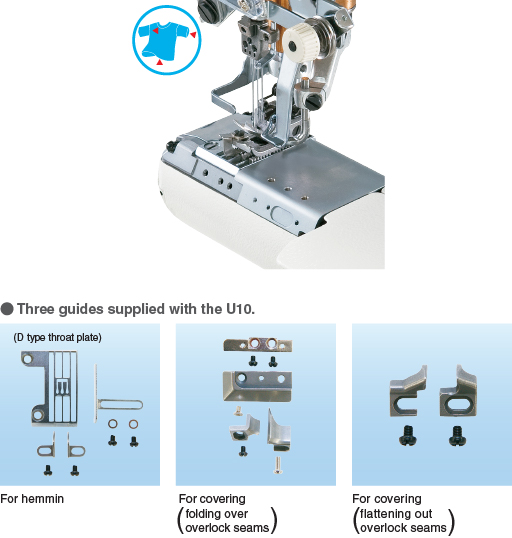

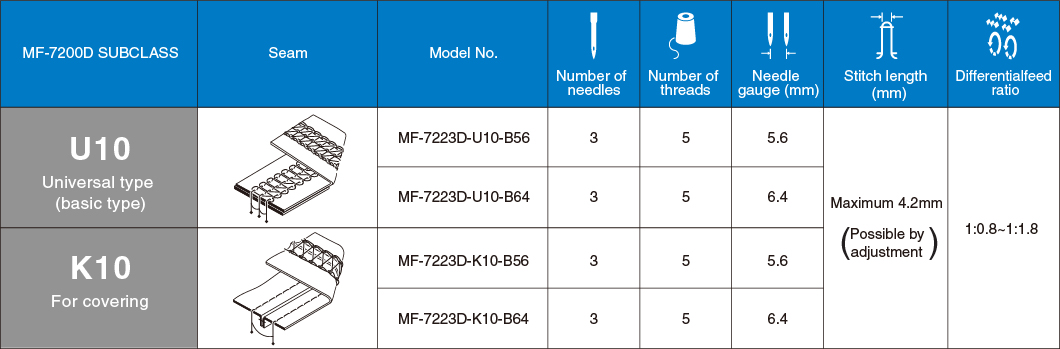

U10 Universal type (basic type)

The machine can be used for the hemming process of the sleeves and bottoms of T-shirts and for the covering process for sportswear and knitwear. It is a basic one which can be used for a broader range of processes independently.

The sewing machine supports hemming and covering (single-side bent and flattening) by the use of the guide supplied with the unit.

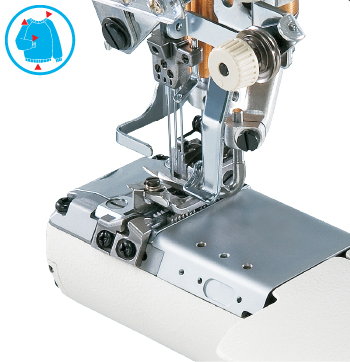

K10 For covering

This model is best sui ted to the covering processes for polo shirts, sportswear and knit outers, etc. The sewing machine has been provided as standard with an exclusive gauge (throat plate, feed dog) and guide for flattening.

The sewing machine is also supplied with a guide for covering (folding over overlock seams) and a hemming guide (excluding the throat plate) as accessories.

Basic performance

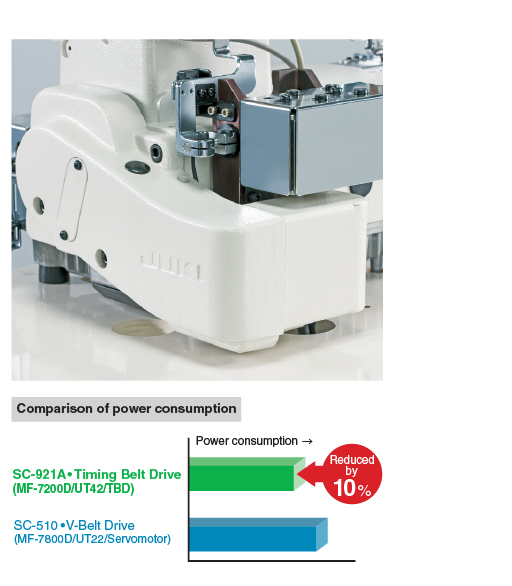

Timing Belt Drive(TBD)

The sewing machine has adopted the timing-belt drive method to achieve sewing without any loss of driving force.

Belt abrasion powder which can stain the product is no longer produced. Setup of the conventional belt is troublesome, but now easier setup of the belt is also achieved by the adoption of the timing belt.

In addition, the motor size has been reduced to achieve energy-saving.

New model control box SC-921A

New model control panel CP-18BThe new model control box SC-921A has been newly developed.

The control box is resistant to voltage fluctuations, noise and vibration.

The new model control box is provided with an energy-saving mode for the first time in a control box for sewing machines. It reduces power consumption during standby time when the motor is not rotating.

The new model operation panel, CP-18B has been adopted.

The CP-18B is installed with a product support function.Output control function

- Target No. of products display mode

- Target-actual result difference display mode

Operation measuring function

- Sewing machine availability display mode

- Pitch time display mode

- Average speed of stitch display mode

* The timing belt drive method and SC-921A/CP-18B have only been adopted by the sewing machine series provided with a thread trimmer (UT42, UT45).

Micro-lifter mechanism

Elastic material or delicate material can be sewn with the presser foot kept slightly raised. This effectively helps reduce the degree of slippage, warpage and damage of the material.

Stitch length adjusting mechanism

Stitch pitch (stitch length) can be adjusted with ease simply by turning the stitch dial.

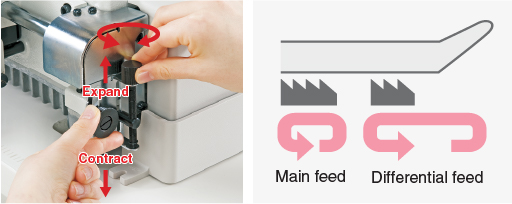

Differential-feed micro-adjustment mechanism

It is possible to finely adjust the differential feed amount to a best-suited value for the material to be used. In addition, the differential feed ratio remains the same even when the stitch length is changed.

Auxiliary cover

The bed seat has been provided as standard with the auxiliary cover.

By using this cover, the sewing machine is not only applicable to the sewing of tubular products, but also to a broad range of processes, as in the case of the sewing machines with a flat bed. In addition, the top-loading binder can be installed with ease.

Specification

| Model name | MF-7200D Series | ||

|---|---|---|---|

| Stitch type | 3-needle top and bottom covering stitch | ||

| Max. sewing speed | 4,000sti/min* | ||

| Needle | UY128GAS (#10S) #9S~#12S | ||

| Lift of the presser foot | 8mm (needle gauge 5.6mm, without top covering stitch), 5mm (with top covering stitch) | ||

| Stitch pitch adjustment | By dial | ||

| Differential feed adjustment | By micro-adjustment mechanism | ||

| Lubrication | Semi-dry/Automatic (frame: no lubrication) | ||

| Lubricating oil | JUKI MACHINE OIL 18 (equivalent to ISO VG18) | ||

| Feed dog inclination adjustment | Provided as standard | ||

| Micro-lifter | Provided as standard | ||

| Needle bar stroke converting function | 31mm | ||

| Silicon oil tank for needle thread | Provided as standard | ||

| Cartridge oil filter | Provided as standard | ||

| Weight of the machine head | 42kg (without device), 44kg (with UT45), 48kg (with UT42) | ||

*"sti/min" stands for "Stitches per Minute."

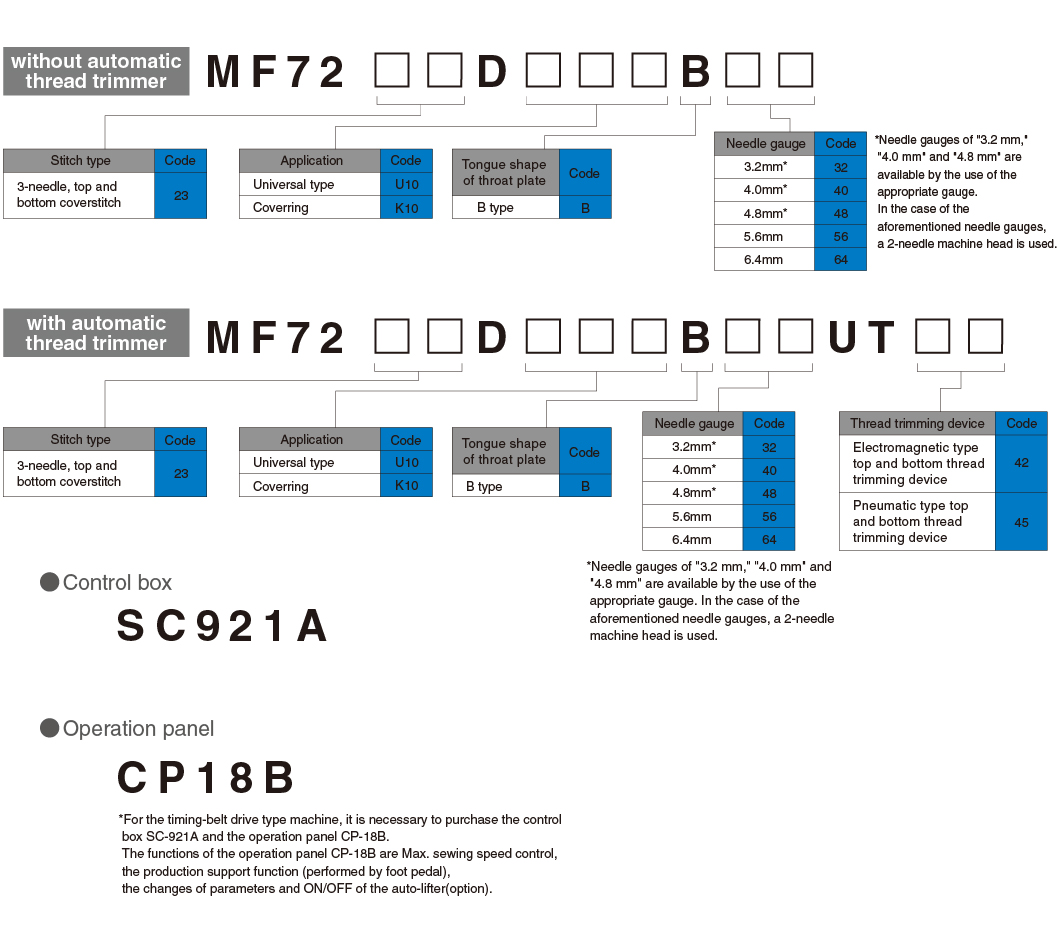

When you place orders

Subclass machine list

Gauge

MF-7223D-U10

MF-7223D-U10/UT

MF-7223D-K10

MF-7223D-K10/UT

| Guage | NEEDLE CLAMP | NEEDLE | NEEDLE PLATE | PRESSER FOOT ASM. | MAIN FEED DOG | DIFFERENTIAL FEED DOG | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

||||

| Needle width | P/N | P/N | P/N | Remarks | P/N | P/N | Remarks | P/N | Remarks | |

| inch | mm | |||||||||

| 7/32 | 5.6 | 13350301 | MUY128S1000 | 40086230 40086242 | U10 K10 |

40082974 | 40086228 40086231 | U10 K10 |

40086229 40090243 | U10 K10 |

| 1/4 | 6.4 | 13350400 | MUY128S1000 | 40090240 40086241 | U10 K10 |

40082974 | 40086228 40086231 | U10 K10 |

40086229 40090243 | U10 K10 |