Semi-dry head, 2-needle Lockstitch Machine

The LH-3500A Series has made further progress. This is the cutting-edge model 2-needle sewing machine which comes with substantially enhanced mechanisms such as the direct-drive mechanism, semi-dry head, new thread tension control mechanism and improved oiling system.

Product features

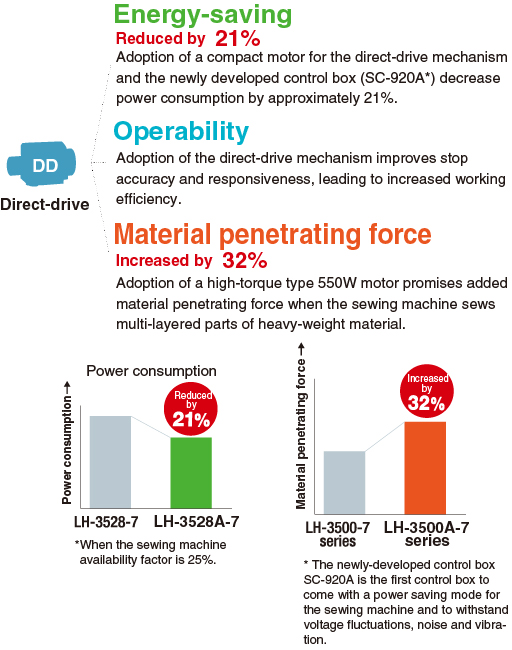

Adoption of the direct-drive mechanism enhances energy conservation and workability, and increases the needle's material penetrating force

A semi-dry head is now installed in all of the models of the LH-3500A SeriesONLY JUKI

All models of the LH-3500A Series are provided with a semi-dry head to eliminate staining with oil from the frame (the needle bar part).

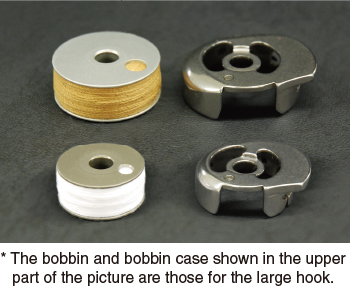

The "large-hook type" uses a hook 1.8 times larger than standard

This increase in size reduces the frequency of bobbin-thread changesThe sewing machine has been designed to eliminate waste time and the operator's stress.

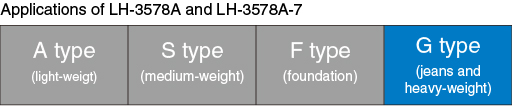

Many different models are prepared according to the type of materials

From a wide variety of models, the best-suited model can be chosen according to your sewing items, ranging from light- to heavy-weight materials.

Production support function

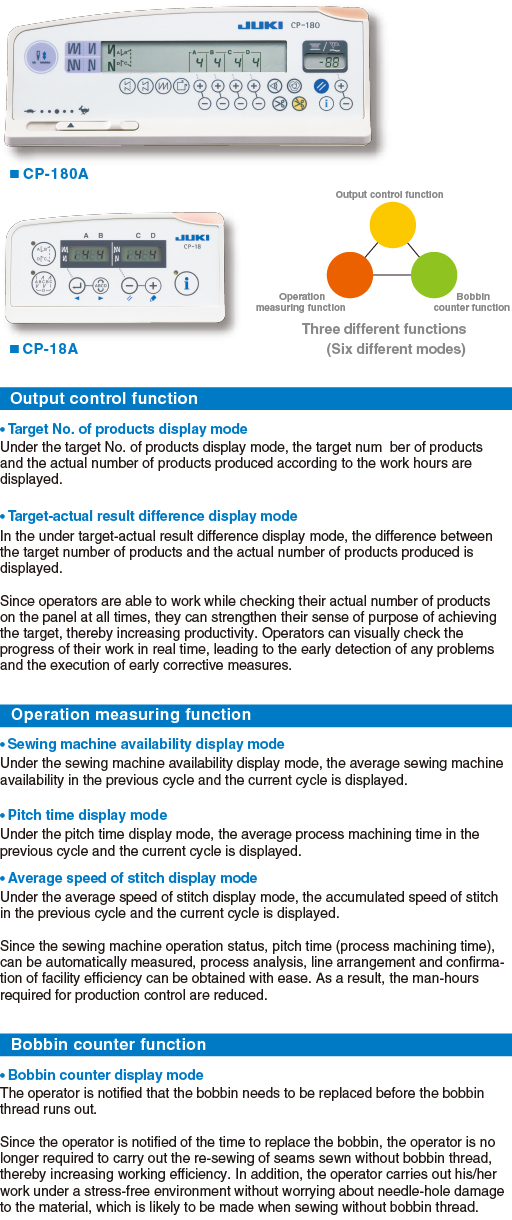

The operation panels CP-18A and CP-180A are provided with a production support function

The production support function actually consists of three different functions (six different modes), which are the output control function, operation measuring function and bobbin counter function. Each with its own production support effect. An appropriate function (mode) can be selected as required.

The parameter setting can be done on the panel located on the top of the sewing machine, thereby helping reduce operator fatigue during setup changing.

Basic performance

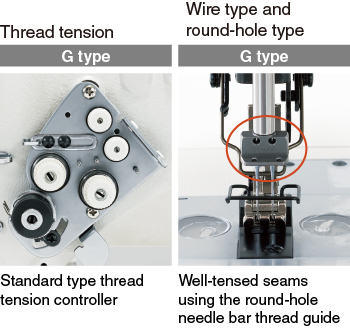

The best-suited thread tension is achieved according to the sewing specificationsUnique to JUKI

Two different types of thread tension controllers have been developed

The needle tension controller comes in two different mechanisms according to the type of sewing machine. For the G types, the sewing range has been broadened to produce well-tensed seams even when thick thread is used.

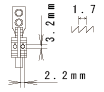

Wire type and round-hole type needle bar thread guide

Two different kinds of needle bar thread guides (needle clamps), the wire type and round-hole type, have been developed according to the type of sewing machine. The round-hole type needle bar thread guide has been adopted for the G types which sew materials requiring well-tensed seams. In addition, the G type is provided as standard with the presser foot with guide which is effective for the topstitching process.

Highly reliable thread-trimming mechanism

Our direct-acting thread trimmer mechanism, which spreads thread without fail, has been further improved. The thread trimmer trims the needle thread and bobbin thread without fail even when thick thread is used. In addition, the thread trimmer's bobbin thread retaining force has been increased.

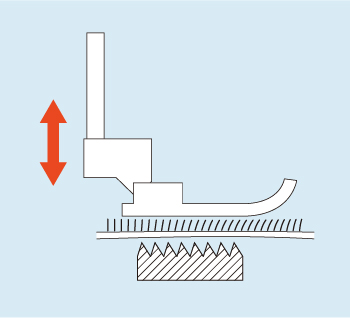

Material-friendly micro-lifter mechanism

The presser foot can be lifted by a minute amount by adjusting the eccentric pin located in the presser lifter lever section. When sewing shaggy and elastic fabrics, the load applied to the material is reduced by slightly lifting the presser foot. Materials are handled more easily and are finished without sacrificing the inherent texture of the material.

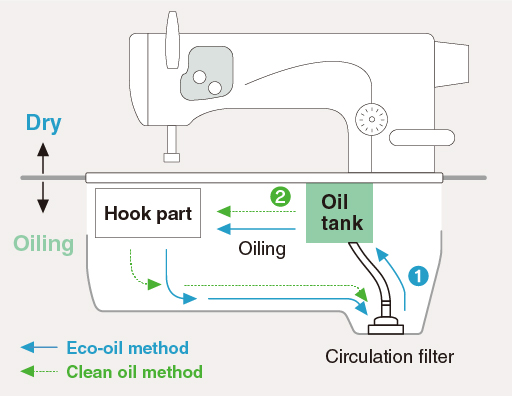

Two selectable new-method oiling mechanismsUnique to JUKI

ECO-oli method (circulation type)

ECO-oli method (circulation type)The oil dropped from the hook and its surrounding sections into the under-cover is filtered to remove dirt and dust and is then returned to the oil tank. This method saves the effort of oiling and reduces oil consumption.

Clean oil method

Clean oil methodThe oil dropped from the hook and its surrounding sections into the under-cover is not returned to the oil tank, but only clean oil is supplied to the hook at all times.

*The oiling method can be changed over as desired.

Specification

| Model name | LH-3578A-G | |||||

|---|---|---|---|---|---|---|

| Application | Jeans and heavy-weight | |||||

| Organized split needle bar mechanism | Not provided | |||||

| Hook | Vertical axis 1.8 times large hook | |||||

| Lubrication | Semi-dry / hook section: minute-quantity lubrication (tank system) | |||||

| Max. sewing speed | 3,000sti/min* | |||||

| Distance from needle to machine arm | 120mm (H) × 266mm (W) × 87mm (height of jaw part) | |||||

| Feed system | Needle-feed | |||||

| Max. stitch length | 5mm | |||||

| Needle bar stroke | 33.4mm | |||||

| Thread take-up | Slide type | |||||

| Tensioner | Standard type | |||||

| Thread winder | Built-in the machine head | |||||

| Lift of the presser foot | 7mm (by hand), 13mm (by knee) | |||||

| Oiling method | Eco-oil method (circulation type), Clean oil method | |||||

| Tank capacity | 280cm³ | |||||

| Lubricating oil | JUKI New Defrix Oil No.1 (equivalent to ISO VG7) | |||||

| Needle | DP×5 (#21) #16~#23 |

|||||

| Outside dimensions of package (mm) | LH-3578A: 718mm (H) × 341mm (W) × 744mm (L) LH-3578A-7: 768mm (H) × 341mm (W) × 744mm (L) |

|||||

| Machine head weight (including the package) | LH-3578A: 48kg LH-3578A-7: 61kg (with AK: 63kg) |

|||||

*"sti/min" stands for "Stitches per Minute."

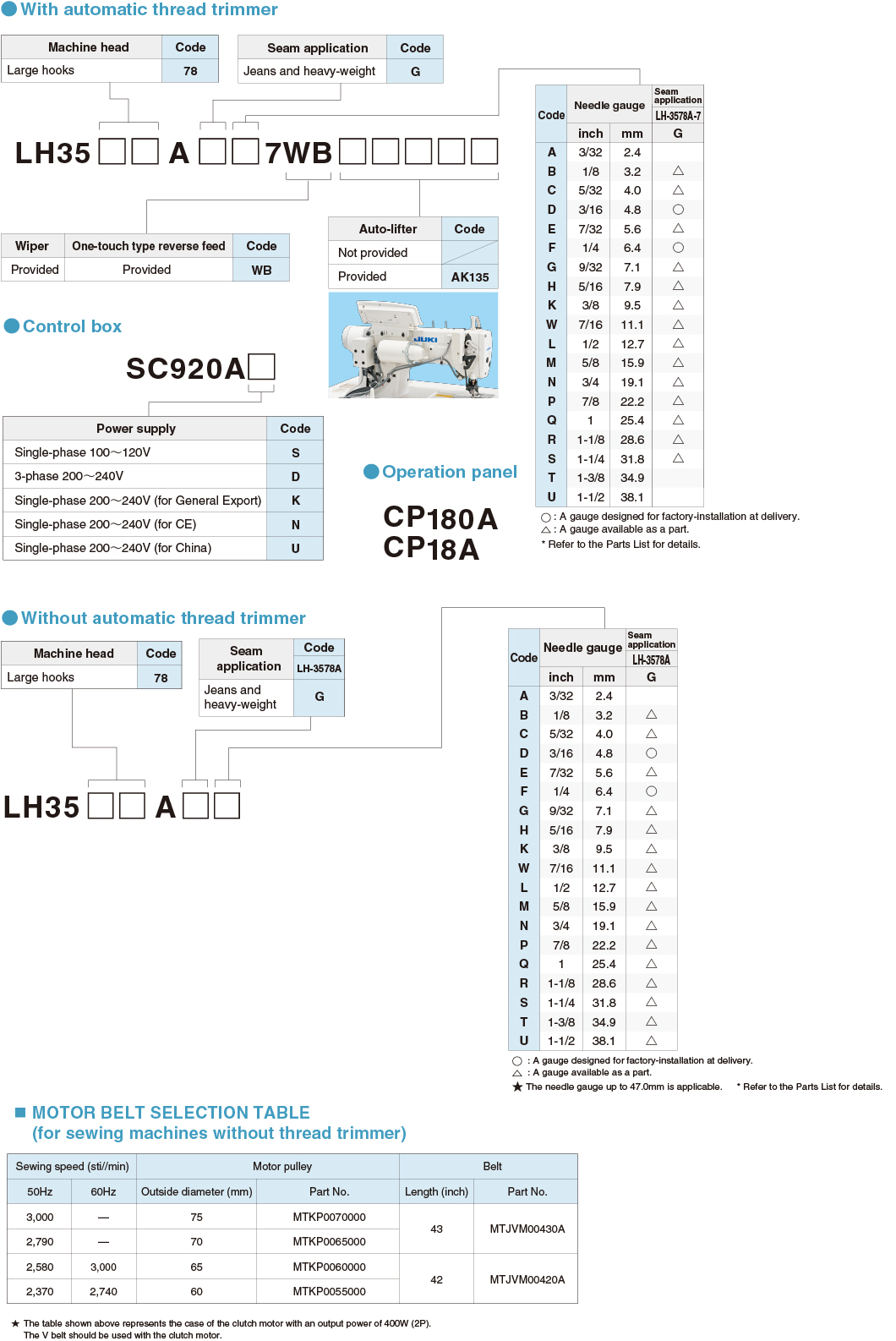

When you place orders

Gauge

LH-3578A-G

| Guage | NEEDLE CLAMP ASM. | FEED DOG | FEED DOG | ||

|---|---|---|---|---|---|

| Figure |  |

|

|

||

| Needle width | P/N | P/N | P/N | ||

| Code | inch | mm | |||

| B | 1/8 | 3.2 | 10147650 | B1613512B0H | - |

| C | 5/32 | 4.0 | 10147759 | B1613512C0H | - |

| D | 3/16 | 4.8 | 10147858 | B1613512D0H | 40025801 |

| E | 7/32 | 5.6 | 10147957 | B1613512E0H | 40025802 |

| F | 1/4 | 6.4 | 10148054 | B1613512F0H | 40025803 |

| G | 9/32 | 7.1 | 10148153 | B1613512G0H | 40025804 |

| H | 5/16 | 7.9 | 10148252 | B1613512H0H | 40025805 |

| K | 3/8 | 9.5 | 10148351 | B1613512K0H | 40025806 |

| W | 7/16 | 11.1 | 10148450 | 40075311 | 40025807 |

| L | 1/2 | 12.7 | 10148559 | B1613512L0H | 40025808 |

| M | 5/8 | 15.9 | 10148658 | B1613512M0H | 40025809 |

| N | 3/4 | 19.1 | 10148757 | B1613512N0H | 40025810 |

| P | 7/8 | 22.2 | 10148856 | B1613512P0H | 40025811 |

| Q | 1 | 25.4 | 10148955 | B1613512Q0H | 40025812 |

| R | 1-1/8 | 28.6 | 10149052 | B1613512R0H | 40025813 |

| S | 1-1/4 | 31.8 | 10149151 | B1613512S0H | 40025814 |

| T | 1-3/8 | 34.9 | 10149250 | B1613512T0H | 40025815 |

| U | 1-1/2 | 38.1 | 10149359 | B1613512U0H | 40025816 |

| Remarks | - | - | Option | ||

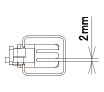

| Guage | PRESSER FOOT ASM._TIP DIVIDED | THROAT PLATE | ||

|---|---|---|---|---|

| Figure |  |

|

||

| Needle width | P/N | P/N | ||

| Code | inch | mm | ||

| B | 1/8 | 3.2 | 40035896 | 40072337 |

| C | 5/32 | 4.0 | 40071909 | 40072338 |

| D | 3/16 | 4.8 | 22816557 | 22625305 |

| E | 7/32 | 5.6 | 22816656 | 22625404 |

| F | 1/4 | 6.4 | 22816755 | 22625503 |

| G | 9/32 | 7.1 | 22816854 | 22625602 |

| H | 5/16 | 7.9 | 22816953 | 22625701 |

| K | 3/8 | 9.5 | 22817050 | 22625800 |

| W | 7/16 | 11.1 | 40033941 | 22625909 |

| L | 1/2 | 12.7 | 22817159 | 22626006 |

| M | 5/8 | 15.9 | 40033945 | 22626006 |

| N | 3/4 | 19.1 | 40033947 | 22626204 |

| P | 7/8 | 22.2 | 40033949 | 22626303 |

| Q | 1 | 25.4 | 40033951 | 22626402 |

| R | 1-1/8 | 28.6 | 40033953 | 22626501 |

| S | 1-1/4 | 31.8 | 40033955 | 22626600 |

| T | 1-3/8 | 34.9 | 40033957 | 22626709 |

| U | 1-1/2 | 38.1 | 40033959 | 22626808 |

| Guage | SLIDE PLATE ASM._LEFT | SLIDE PLATE ASM._RIGHT | SLIDE PLATE ASM._LEFT | SLIDE PLATE ASM._FRONT | ||

|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

||

| Needle width | P/N | P/N | P/N | P/N | ||

| Code | inch | mm | ||||

| A | 3/32 | 2.4 | 22601058 | 22600555 | 40051633 | 40042874 |

| B | 1/8 | 3.2 | 22601058 | 22600555 | 40051633 | 40042874 |

| C | 5/32 | 4.0 | 22601058 | 22600555 | 40051633 | 40042874 |

| D | 3/16 | 4.8 | 22601058 | 22600555 | 40051633 | 40042874 |

| E | 7/32 | 5.6 | 22601058 | 22600555 | 40051633 | 40042874 |

| F | 1/4 | 6.4 | 22601058 | 22600555 | 40051633 | 40042874 |

| G | 9/32 | 7.1 | 22601058 | 22600555 | 40051633 | 40042874 |

| H | 5/16 | 7.9 | 22601058 | 22600555 | 40051633 | 40042874 |

| K | 3/8 | 9.5 | 22601058 | 22600555 | 40051633 | 40042874 |

| W | 7/16 | 11.1 | 22601058 | 22600555 | 40051633 | 40042874 |

| L | 1/2 | 12.7 | 22601157 | 22600654 | 40045729 | 40042874 |

| M | 5/8 | 15.9 | 22601157 | 22600654 | 40045729 | 40042874 |

| N | 3/4 | 19.1 | 22601157 | 22600654 | 40045729 | 40042874 |

| P | 7/8 | 22.2 | 22601256 | 22600753 | 40045730 | 40042874 |

| Q | 1 | 25.4 | 22601256 | 22600753 | 40045730 | 40042874 |

| R | 1-1/8 | 28.6 | 22601256 | 22600753 | 40045730 | 40042874 |

| S | 1-1/4 | 31.8 | 22601355 | 22600852 | 40045731 | 40042874 |

| T | 1-3/8 | 34.9 | 22601355 | 22600852 | 40045731 | 40042874 |

| U | 1-1/2 | 38.1 | 22601355 | 22600852 | 40045731 | 40042874 |

| Remarks | - | - | Option | - | ||

LH-3578AG-7

| Guage | NEEDLE CLAMP ASM. | FEED DOG | FEED DOG | PRESSER FOOT ASM._TIP DIVIDED | SWIVEL GUIDE PRESSER ASM. | THROAT PLATE | ||

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

||

| Needle width | P/N | P/N | P/N | P/N | P/N | P/N | ||

| Code | inch | mm | ||||||

| A | 3/32 | 2.4 | 10147551 | - | - | - | - | - |

| B | 1/8 | 3.2 | 10147650 | 40053705 | 40053705 | 40035896 | - | 40035881 |

| C | 5/32 | 4.0 | 10147759 | 40071911 | - | 40071909 | - | 40025485 |

| D | 3/16 | 4.8 | 10147858 | 40035891 | 40025831 | 22816557 | 40095293 | 40095289 |

| E | 7/32 | 5.6 | 10147957 | 40050009 | 40025832 | 22816656 | - | 40025491 |

| F | 1/4 | 6.4 | 10148054 | 40035892 | 40025833 | 22816755 | 40094776 | 40094773 |

| G | 9/32 | 7.1 | 10148153 | 40050010 | 40025834 | 22816854 | - | 40025493 |

| H | 5/16 | 7.9 | 10148252 | 40050011 | 40025835 | 22816953 | - | 40025494 |

| K | 3/8 | 9.5 | 10148351 | 40035893 | 40025836 | 22817050 | - | 40025495 |

| W | 7/16 | 11.1 | 10148450 | - | 40025837 | 40033941 | - | 40025496 |

| L | 1/2 | 12.7 | 10148559 | 40035894 | 40025838 | 22817159 | - | 40025498 |

| M | 5/8 | 15.9 | 10148658 | 40071912 | 40025839 | 40033945 | - | 40025499 |

| N | 3/4 | 19.1 | 10148757 | 40035895 | 40025840 | 40033947 | - | 40025500 |

| P | 7/8 | 22.2 | 10148856 | 40071913 | 40025841 | 40033949 | - | 40025502 |

| Q | 1 | 25.4 | 10148955 | 40071914 | 40025842 | 40033951 | - | 40025503 |

| R | 1-1/8 | 28.6 | 10149052 | 40071915 | 40025843 | 40033953 | - | 40025504 |

| S | 1-1/4 | 31.8 | 10149151 | 40071916 | 40025844 | 40033955 | - | 40025505 |

| T | 1-3/8 | 34.9 | 10149250 | - | - | - | - | - |

| U | 1-1/2 | 38.1 | 10149359 | - | - | - | - | - |

| Remarks | - | - | Option | - | - | - | ||

| Guage | SLIDE PLATE ASM._LEFT | SLIDE PLATE ASM._RIGHT | SLIDE PLATE ASM._LEFT | SLIDE PLATE ASM._RIGHT | ||

|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

||

| Needle width | P/N | P/N | P/N | P/N | ||

| Code | inch | mm | ||||

| B | 1/8 | 3.2 | 40025247 | 40025235 | 40051633 | 40042880 |

| C | 5/32 | 4.0 | 40025247 | 40025235 | 40051633 | 40042880 |

| D | 3/16 | 4.8 | 40025247 | 40025235 | 40051633 | 40042880 |

| E | 7/32 | 5.6 | 40025247 | 40025235 | 40051633 | 40042880 |

| F | 1/4 | 6.4 | 40025247 | 40025235 | 40051633 | 40042880 |

| G | 9/32 | 7.1 | 40025247 | 40025235 | 40051633 | 40042880 |

| H | 5/16 | 7.9 | 40025247 | 40025235 | 40051633 | 40042880 |

| K | 3/8 | 9.5 | 40025247 | 40025235 | 40051633 | 40042880 |

| W | 7/16 | 11.1 | 40025247 | 40025235 | 40051633 | 40042880 |

| L | 1/2 | 12.7 | 40025248 | 40025236 | 40045729 | 40042880 |

| M | 5/8 | 15.9 | 40025248 | 40025236 | 40045729 | 40042880 |

| N | 3/4 | 19.1 | 40025248 | 40025236 | 40045729 | 40042880 |

| P | 7/8 | 22.2 | 40025249 | 40025239 | 40045730 | 40042880 |

| Q | 1 | 25.4 | 40025249 | 40025239 | 40045730 | 40042880 |

| R | 1-1/8 | 28.6 | 40025249 | 40025239 | 40045730 | 40042880 |

| S | 1-1/4 | 31.8 | 40025250 | 40025240 | 40045731 | 40042880 |

| Remarks | - | - | Option | - | ||