M900/DJ

![]()

JUKI × Pegasus

JUKI and PEGASUS 1st Model by Joint Development

The M900/DJ Series is the first product to be jointly developed as part of the business alliance between JUKI and Pegasus announced in 2021. This product is a fusion of Pegaus' product and manufacturing expertise in overlock sewing machines and JUKI's advanced direct drive technology.

(Product sold exclusively overseas)

JUKI and PEGASUS 1st Model by Joint Development M900/DJ series Release

Integrated head & motor

Energy saving and improved sewing machine operational responsiveness

Conventionally, the main shaft of a sewing machine and the motor that drives it were connected by a belt and operated. By installing a motor in the head of the sewing machine and connecting it directly to the main shaft, the operating responsiveness of the sewing machine when the pedal is pressed has been dramatically improved.

In addition, because the energy of the motor can be directly transferred to the operation of the sewing machine, it saves about 70% energy compared to the conventional belt-type model.

Sensor thread cutter

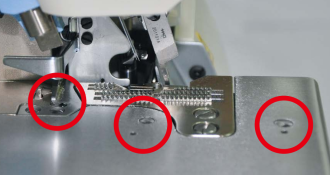

2 types of sensor detection system

Sensors are placed on the plate to detect the edge of fabric for switching between (1) lifter, (2) auto chain-off thread trimming, (3) suction of waste chain-off thread and fabric dust.

*DJ21/22 have a 2-point sensor, and DJ23 has a 3-point sensor.

3 types of thread cutters

KH cutter (flat type) : Thread cutter with horizontal type chain suction device

KS cutter (side type) : Thread cutter with vertical type chain suction device

AT cutter (chopper type) : Automatic tape/chain-off thread cutter

3 operation modes

Three operation modes can be set in combination with the operation mode and the presser foot lifter mode, depending on the work process and the operator's skill level.

Manual mode

Lift up the presser foot by pedal -> Sewing start by pedal -> Thread trimming by pedal

Semi-automatic mode

Automatically lift up the presser foot by sensor -> Sewing start by pedal -> Automatic thread trimming by sensor -> Automatic stop after thread trimming

Full automatic mode

Automatically lift up the presser foot by sensor -> Automatic sewing start by sensor -> Automatic thread trimming by sensor -> Automatic stop after thread trimming

Safety sensor

Sensors are placed at 3 locations : (1) eye guard, (2) cloth plate cover, (3) presser foot arm, so that the sewing machine will not operate for safety reasons if any of the locations are not in the correct position. This prevents accidents due to unexpected operation of the sewing machine by the operator.

Needle thread releasing device

The automatic needle thread releasing device (SC device: Strechable Chain) reduces the weight of the thread chain by releasing the thread chain on the blank, making it easier to suck. It also allows the thread chain to be cut shorter, reducing thread consumption.

*Available on DJ21/22 only.

LED Light

In addition to the white color of ordinary LED lights, warm light colors are provided, and three different color tones can be selected by combining the color tones. In addition, brightness can be adjusted in five levels.

By selecting the color tone and brightness according to the operator and work environment, operator fatigue is reduced.

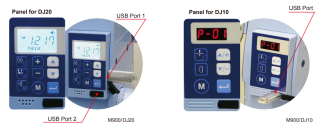

USB Port

The head-integrated panel comes standard with a USB port for easy software updates. It also has a 1.0A power supply, allowing use of air fans and charging of smartphones. *DJ21/22/23 types have two USB ports, and DJ10 type has one.