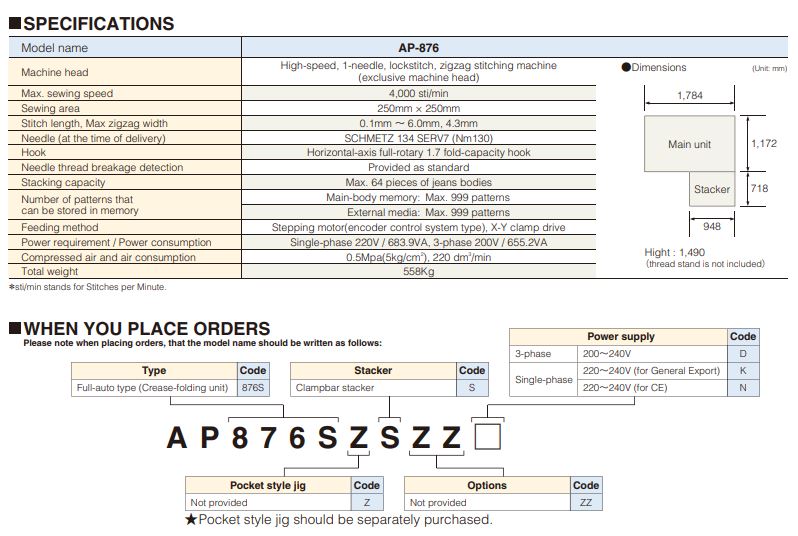

AP-876

![]()

De-skill & high productivity

Automation reduces manpower and de-skills the workforce

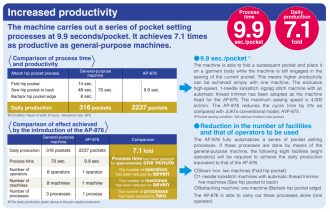

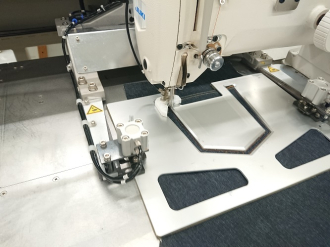

High productivity is realized with a single machine that can perform overlapping operations of pocket setting, folding, and sewing.

In addition, a series of pocketing processes are fully automated to reduce manpower and eliminate the need for skilled operators.

Prevent fabric flapping

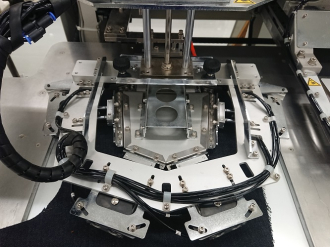

A pocket cloth is folded on the table surface and properly tensed by a pocket style jig to create sharp creases without material slippage or bulging.

The pocket cloth is vertically shifted and pulled to the suitable tautness for placement on the garment body.

This prevents the pocket cloth from slipping out of the correct position and makes it easy to adjust folding timing.

With this pocket-folding and pocket-positioning mechanism, the machine is widely adaptable to various materials.

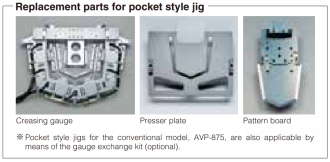

Easy jig change

The pocket style jig can be changed in less than five minutes without requiring a tool.

This means that the machine supports small-lot production flexibly.

Active tension

Market-proven active tension has been introduced to the needle thread tension controller.

Pinpoint adjustment of the needle thread tension is enabled during sewing.

Data on the thread tension setting relative to the material thickness and thread tension correction which varies depending on the sewing direction can be entered through the operation panel on a stitch-by-stitch basis.

The needle thread tension is reproducible.

This reduces the setup time required when changing the material thickness.

Stacker

The stacker can stack 64 pieces of finished products at the maximum.

In addition, the stacker is equipped as standard with a stacker-capacity detector.

The stacker can be stored inside the main body of the AP-876 sewing machine.

Stacker can be retracted by operating the operation panel (IP-420).

This system is very helpful when moving the machine.

Large color touch panel

The AP-876 has adopted, as its operation panel, the IP-420 which has a large color liquid crystal touch panel.

Entry and modification of sewing data can now be carried out on the main body of the sewing machine.

In addition, the machine supports USB, allowing for the use of various USB thumb drives and media. (SD Card, CF, SM, FD)

[PM-1] *Sewing data creation and editing software PM-1 (separately available) allows you to easily input, check, and correct more detailed sewing data than IP-420.