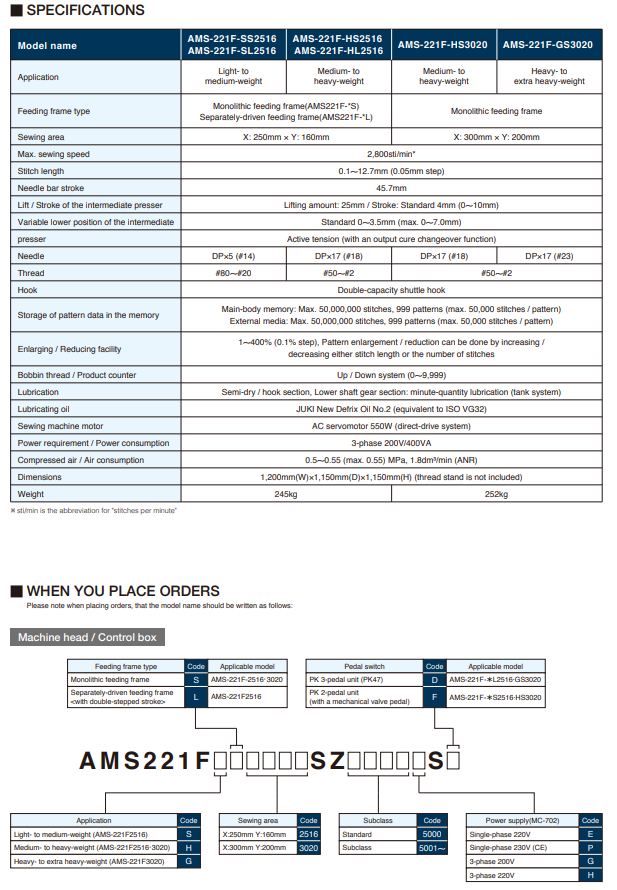

AMS-221F

![]()

Digitization

IoT Data management

Sewing machine parameter can be transfered contactlessly from any commercially available Android device. Uniform settings to multiple sewing machines, as well as checking and changing their status, are easy.The operation panel is also equipped with a USB port as a standard feature, making it easy to manage data between devices and upgrade software versions. Sewing data can be stored up to 50,000,000 stitches and 999 patterns (maximum 50,000 stitches per pattern).

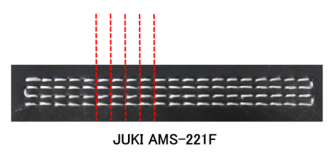

Needle entry point

Industry's most accurate needle entry point is ensured

Increased rigidity and JUKI's unique high-performance feed control system contribute to increased feed accuracy, thereby reducing uneven material feed during outward/inward sewing. Uneven material feed during outward/inward sewing is reduced. In addition, for the feed system of the feeding frame, either the intermittent feed or the continuous feed can be selected.

Active tension

Highly-evaluated active tension that is used for setting the needle thread tension is now added with new functions. The output can be changed over with the memory switch between the low-tension side output and the high-tension side output to enable fine adjustment of the thread tension in the actual area of use. All of these adjustments can be done on a stitch-by-stitch basis through the operation panel with ease. And, set up changing time is reduced at the time of changeover of processes.

Direct drive

AMS-221F has adopted the direct-drive system by means of a compact AC servomotor. Thanks to the capabilities enabled by the direct-drive system such as the panel screen display OFF feature and motor-excitation OFF feature, the power consumption is reduced by 12.2% as compared with the AMS-221EN.

Two different types of feeding frames

The feeding frame comes in two types; one is the monolithic feeding frame and the other is the separately-driven feeding frame (consisting of separate right and left parts). Since the right and left parts of separately-driven feeding frame can be operated independently, easier placement of the material under the feeding frame is promised. The amount of lift and lifting/lowering speed of the feeding frame can be set separately for its right and left parts.

Bird's nest & remaining thread reduction

Bird's nest reducing function

Since thread trimming is performed at the beginning of sewing, so-called bird's nest (thread tangling in at the beginning of sewing) is reduced, thereby producing more beautiful seams.

Shorter thread remaining function

Since the counter knife position has been changed, length of needle thread and bobbin thread remaining on the material after thread trimming is reduced to 5 mm or less. As a result, securing of thread at the end of sewing is no longer required.

* The bird's nest reduction function and shorter-thread remaining function cannot be used simultaneously.

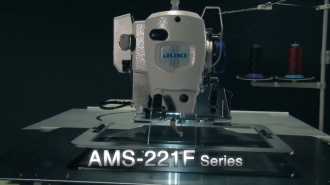

Specification