AE-200AN

![]()

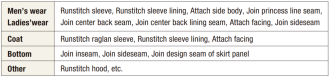

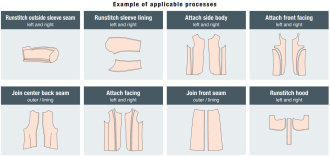

Applications

It is applicable to many different processes such as sewing the center of back of men’s and ladies’ jackets and joining the sides of ladies’ skirts.

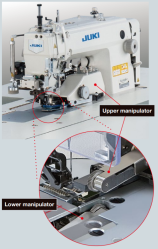

De-skilling

It is applicable to the sewing of materials with different curves and different-in-kind materials.

The AE-200A uses JUKI's unique technology to make it possible for inexperienced operators to sew this difficult and skilled process simply by setting the fabric.

High productivity

The operator is only required to place materials on the sewing machine.

The sewing machine automatically and continuously sews the materials while aligning the materials’ ends until the sewing end is reached.

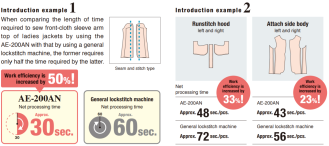

When comparing the length of time required to sew front-cloth sleeve arm top of ladies jackets by using the AE-200AN with that by using a general lockstitch machine, the former requires only half the time required by the latter.

Improve workability

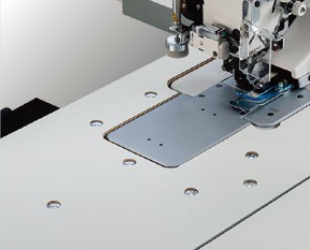

Air blow table

Air blow to assist feed the material is provided as standard to improve workability.

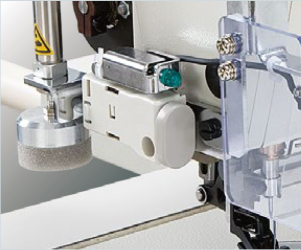

Handy switch

The start/pause switch is provided close at hand as standard.

The switch is located near the position where the operator places the materials on the sewing machine, allowing the operator to carry out sewing in a responsive manner.

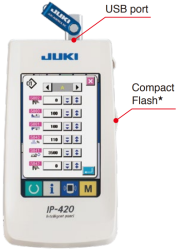

Color touch panel

The larger LCD makes it easy to select a sewing pattern and set the number of stitches, allowing intuitive operation.

In addition, settings of the pressure and differential feed amount of the manipulator can be checked at a glance, reducing the time required for pattern changes.

Pin-tuck specification

The AE-200ANLD is able to produce beautiful and equally-spaced pin tucks by installing the pin tuck device (40088621).

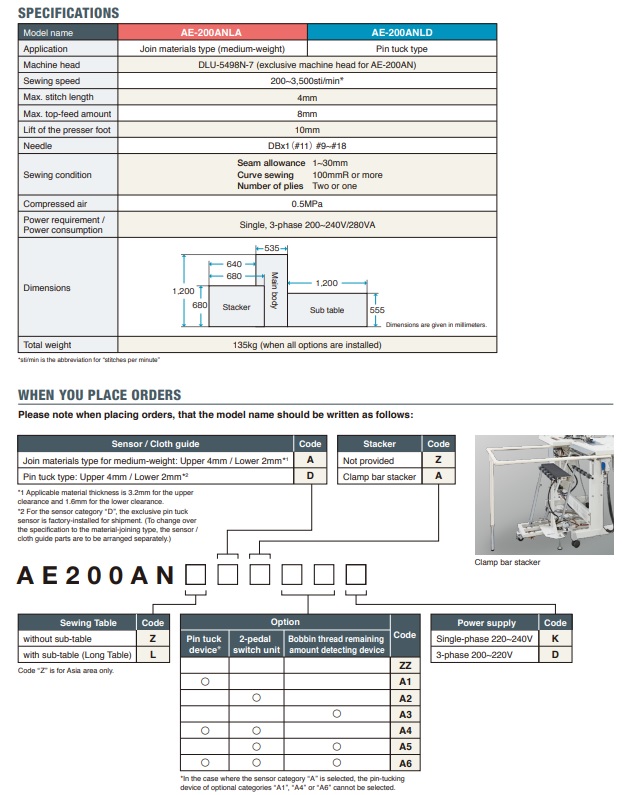

Specification