Conceptual illustration of the JUKI booth

JUKI will be showcasing its industrial and household sewing machines at Texprocess 2024, a major exhibition to be held at the Frankfurt International Exhibition Center in Frankfurt am Main, Germany, from April 23 to 26 this year.

The industrial segment exhibit will be introducing state-of-the-art machines and services that make up a total solution for your production line, based on the concept of “JUKI Smart Solutions -Innovation with our Best Global Support”.

Visit the special section to experience JUKI’s newest systems and machines, including the winner of the Texprocess Innovation Awards 2024. Experience JUKI’s non-apparel products item by item, alongside apparel-focused products developed to promote automation and seamless operation.

In the non-apparel category, we will be exhibiting the PLK-J series developed by JUKI Techno Solutions. In the apparel category, visitors will see products jointly developed with PEGASUS and equipment created to extend the JUKI lineups.

Our JaNets system exhibit will demonstrate how digital sewing machine specifications can be seamlessly changed by transmitting information customized to the fabric used. Visitors will also experience JUKI’s latest solutions for the IoT era, such as JUKI-ShuHaRi, a cloud system that enables preventive maintenance and daily inspections using a dedicated smartphone app.

The home segment exhibit will introduce a household sewing machine, a compact overlock/safety stitch machine, and a professional sewing machine that recently won the Good Design Award sponsored by the Japan Institute of Design Promotion.

JUKI Booth Exhibit Outline

|

Location |

Frankfurt International Exhibition Center in Frankfurt am Main, Germany |

|

|

Exhibition space |

400 m² |

|

|

Number of models exhibited |

Industrial sewing machines |

39 models (including 5 new models and 4 models to be released soon) |

|

Household sewing machines |

3 models(including 1 new models) |

|

|

Exhibition Concept |

JUKI Smart Solutions - Innovation with our Best Global Support - |

|

Outline of each corner and main exhibits

1. Automotive (Car seats/Air bags)

Models suitable for the sewing of car components such as car seats and air bags.

2. Safety(Belts, Ropes), Furniture

Models suitable for the sewing of belts, ropes, and fabrics.

3. Leather goods

Models suitable for the sewing of products made of leather.

4. Automatic Machines for Apparel Products

Automatic sewing machines developed to raise mass production, labor-saving, and deskilling to unrivalled levels in the manufacture of apparel.

5. New Technology

Next-generation digital sewing machines incorporating forefront technologies. The winner of the Texprocess Innovation Awards 2024 will also be introduced.

6. JaNets Line (Polo Shirts/Underwear)

A production line that acquires digital sewing machine data through JaNets JT Simple for the optimal manufacture of apparel such as polo shirts and underwear.

7. Seamless

The latest bonding machine models that process fabrics without using sewing machines.

8. Parts and Support System Consultation

Parts that improve quality and raise production capacity, as well as “JUKI-ShuHaRi" and “JUKI e-learning" – a preventive maintenance system and education system for operator use will be introduced.

9. Home Sewing

A household sewing machine, a compact overlock/safety stitch machine, and a professional sewing machine selected as winners of the Good Design Award in Japan will be introduced.

New Products

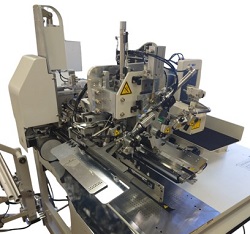

PLK-J6040R/AW-3SD

Computer-controlled Cycle Machine with an Input Device (Full-rotary, Double-capacity Hook Type, with an Automatic Bobbin Thread Winding and Feeding Device)

A computer-controlled cycle sewing machine with a full-rotary, double-capacity hook, retrofittable with an automatic bobbin thread winding and feeding device.

The automatic bobbin thread winding and feeding device can be attached to your JUKI computer-controlled cycle sewing machine to further improve the quality, productivity, and operability of your sewing works. Without the AW3 attachment, bobbins are replaced manually by the operator in the conventional fashion. With the attachment, the machine automatically winds the spare bobbin thread during sewing and replaces the bobbin before the thread runs out. Operators can focus on their work without worrying about winding the bobbin or running out of thread.

AMS-224EN-HS4530RSW/Camera Specifications

Computer-controlled Cycle Machine with an Input Device (Full-rotary, Double-capacity Hook Type, with an Automatic Bobbin Thread Winding and Feeding Device and Camera Specifications)

A computer-controlled cycle sewing machine with a full-rotary, double-capacity hook and image recognition device, retrofittable with an automatic bobbin thread winding and feeding device.

The camera recognizes misalignments caused by the stretching or shrinkage of fabric during sewing to enable the automatic correction of the next sewing position. The machine’s accurate response to the condition of the fabric promises a beautiful sewing finish.

Visitors will see the machine at work on the perforation process for car seats.

APW-896N-RA12ZR2K/X70443

Lockstitch, Automatic Welting Machine (Slanted Flap Type, with an Automatic Flap Feeding Device)

A 2-needle lockstitch sewing machine with a single-needle stop and an electronically adjustable corner-knife cutting system for the sewing of parallel double welts, parallel single welts, slanted double welts, slanted single welts, and trapezoidal stitches (with and without flaps).

Equipped with an automatic flap feeding device, the cycle time (including setting) is reduced and productivity is greatly improved.

Visitors will see the machine at work on the sewing of pockets with flaps using the automatic flap feeding device.

PLC-2710NV-M70BBZ/JEUX0031_700

Semi-dry Direct-drive, Post-bed, Unison-feed, Lockstitch Sewing System with a Vertical-axis Small Hook

(Long arm, area expansion type)

A semi-dry direct-drive, post-bed, unison-feed, digital sewing machine equipped with a small, vertical-axis hook. All of the major sewing parameters—thread tension, stitch length, sewing speed, presser foot pressure, alternate vertical movement, etc.—are digitized to enable fast adjustments and guarantee 100% reproducibility of sewing quality without requiring operating experience or skill.

Visitors will see the machine at work on the sewing of car seats.