MS-1261A/DWS

![]()

Multi-layered part detection sensor

The presser foot pressure control function equipped with a multi-layered part detection sensor as standard enables control of presser foot pressure suitable for different fabric thicknesses, such as sewing inseam, to realize high-quality sewing.

In combination with the belt-type digital cloth puller which enables digital setting of the belt presser foot pressure and feed length, the sewing machine achieves "more beautifully-finished seams".

Belt-type digital cloth puller

This belt-type digital cloth puller prevents stitch skipping and stitch gathering that are likely to occur at multi-layered parts of material.

The "belt presser foot pressure" and "feed length" can be set on the operation panel of the sewing machine.

The digital cloth puller can be lifted up only by operating the lever.

Prevention of stitch skipping

Through the improvement to the feed locus, needle bending is prevented by decreasing the feed amount when the needle penetrates the material. As a result, the looper thread is securely retained to ensure stable loop formation, thereby allowing the looper to catch the needle thread appropriately to produce seams without fail. In addition, the backward-moving type needle guard helps feed heavy-weight materials smoothly, thereby preventing the occurrence of stitch skipping.

Improved operability and energy saving

In pursuit of ease of sewing and ease of handling of materials, the MS-1261A/DWS has adopted newly-developed machine head the shape of which is like of the general-purpose sewing machines.

The MS-1261A/DWS is the first sewing system that comes with an energy-saving high-powered direct-drive motor. As a result, workability and maintainability are improved.

Digitalization

Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially-available Android tablet in contactless mode. This enables quick check for uniform settings as well as confirmation of conditions of sewing machines in a sewing line, thereby facilitating setup changes.

The operation panel also has a USB port as standard, allowing easy data management between devices and software version upgrades.

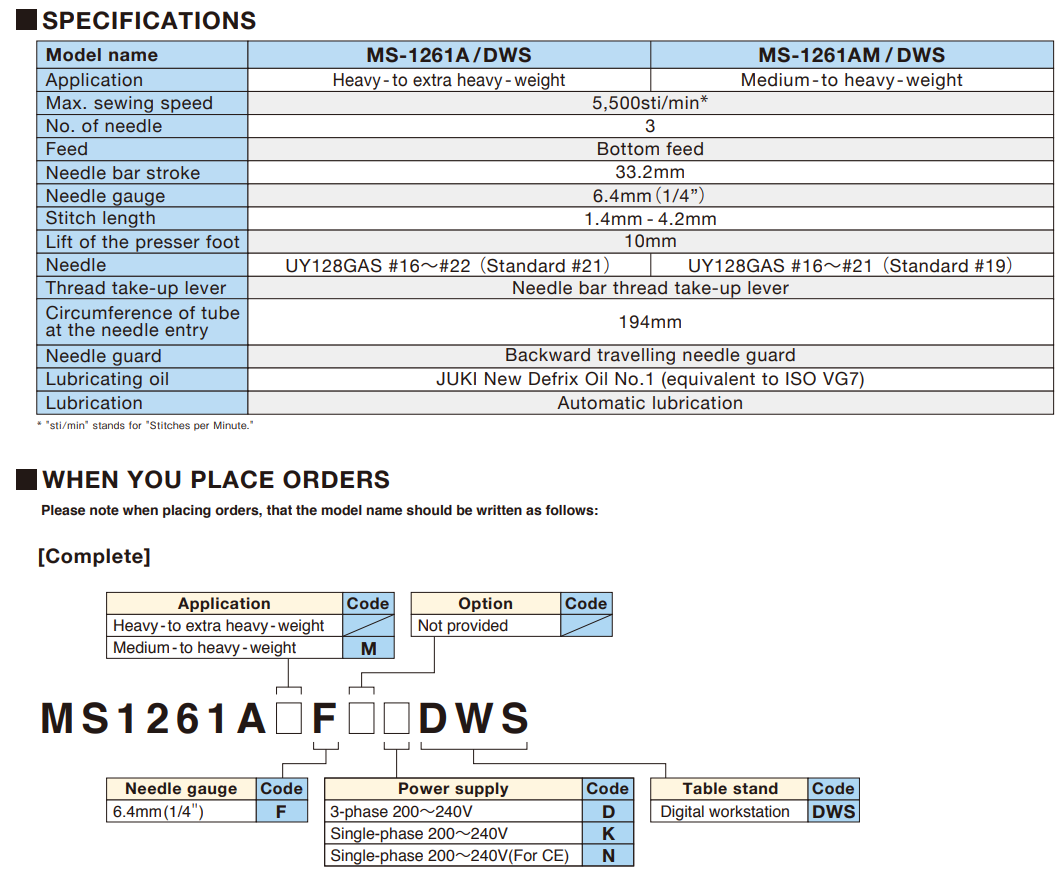

Specification