MOL-254

![]()

Machine time 1.2 sec.

The head, developed for belt-loop attaching machine, installs a direct-drive system to achieve good start-up and short sewing time.

High speed belt-loop feeding realizes a machine time of 1.2 seconds per belt-loop (with 28 stitches).

Smooth belt-loop feeding device

Belt-loops are fed out by the conventional gear-roller feeding mechanism and also drawn out by the new drawing mechanism on the clamp device. Supported by these two mechanisms, the folding fork catches “curled” or “creased” belt-loops every time and supplies them to the head. In addition, the sensor of the clamp device detects the presence/absence of belt-loops. If it detects a faulty belt-loop feed, the clamp device automatically repeats the clamping action. Since the operator doesn't have to operate the set-back switch, less time is lost.

Automatic detection of splice

The machine preliminarily detects each splice in the belt-loops and efficiently disposes them. This means that even when the machine carries out the splice-disposal procedure, the belt-loop feeding device can complete its belt-loop supply action and supply the next belt-loop well before the machine starts to sew.

As a result, the operator can perform rhythmical and efficient sewing work with no delay in cycle time. By detecting changes in the material thickness, the machine's potentiometer finds splice in belt-loops and disposes them perfectly.

When changing the material to be sewn, the change in the material thickness recognized by the potentiometer as a splice can be easily adjusted and programmed through the machines's teaching function.

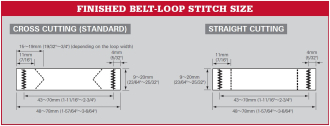

Easy cross and straight cut switching

The applicable loop width for the cross-cutting device is increased. In this model, both the cross-cutting device and the straight-cutting device can now cut loop up to 20mm width.

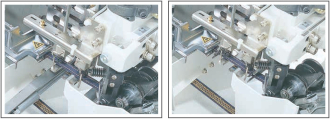

Electric sliding mechanism

The newly incorporated electric sliding mechanism is used to electrically shift the front hook when replacing the bobbin or conducting maintenance on nearby components in order to widen the space between the hooks and facilitate the job.

In addition, when changing the needle gauge, the front hook can be finely positioned in increments of 0.01mm through the operating panel, thereby allowing the operator to easily adjust the distance between the blade points of the two shuttle hooks.

Since the machine no longer requires any adjustment in the hook timing (phase), needle gauge adjustment is much simpler than ever before.

Specification